The price of Chinese flanges is so cheap, is the quality guaranteed?

I. Introduction

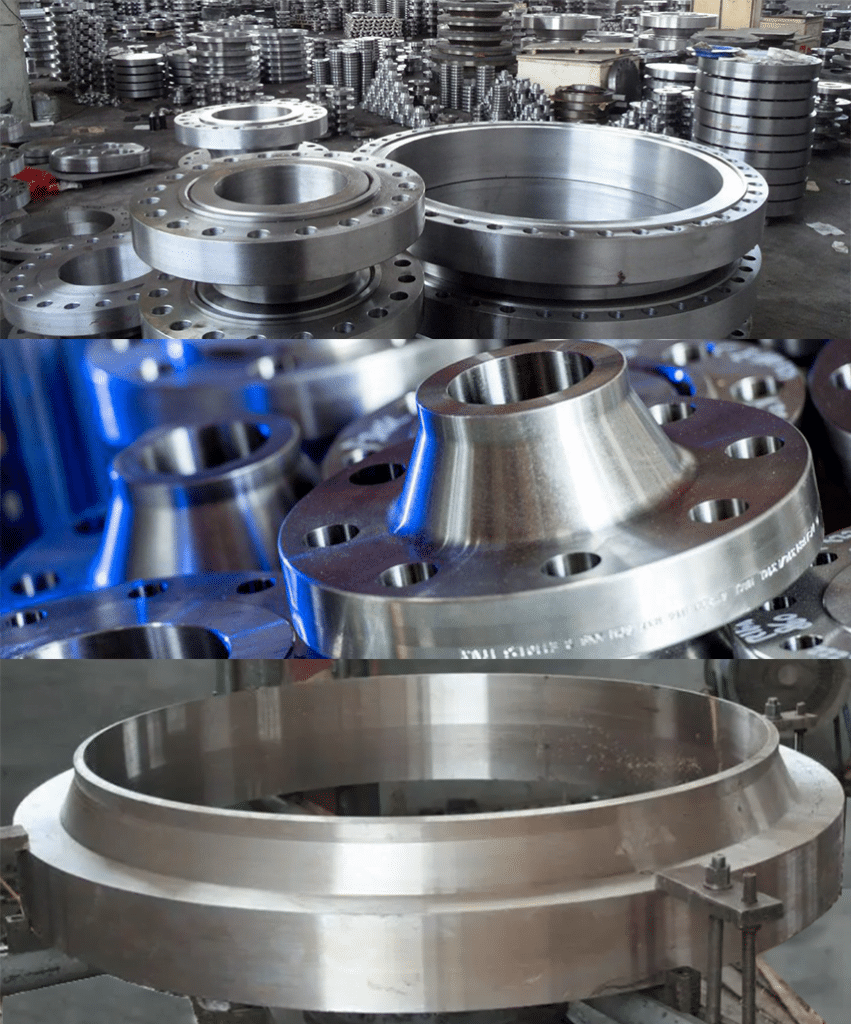

When it comes to purchasing industrial equipment, price is always an important factor. In recent years, the Chinese flange industry has been expanding rapidly, providing attractive prices for its products such as flanges, fittings, and pipes. However, many customers are left wondering whether these cheaper prices come at a cost to quality. Here at Yanhao Pipeline Equipment Co., Ltd., we understand why customers may have concerns about Chinese flanges quality.

In this blog post, we will delve into the Chinese flange industry’s current state and examine the factors affecting Chinese flange prices, including labor, raw materials, and production processes. We will also provide evidence to demonstrate how we, at Yanhao Pipeline Equipment Co., Ltd., uphold the highest standards of quality control in our products.

We hope this post will shed light on some of the misconceptions surrounding Chinese flanges’ quality and help customers make informed decisions when purchasing industrial equipment.

II. Chinese flange industry overview

The Chinese flange industry has been experiencing significant growth in recent years, thanks to the country’s booming industrial sector. As a result, China has become the world’s largest producer and exporter of flanges, with an estimated 38% share of the global flange market.

According to research by QYR Consulting, the Chinese flange industry was valued at approximately 8.9 billion USD in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 3.7% from 2020 to 2026. The report also highlights that the country’s increasing demand for energy and rapid industrialization continue to drive the industry’s growth.

Comparatively, flanges produced in other countries such as the United States, Germany, and Japan have been known to be of high quality and are often favored by customers who prioritize quality over price. However, Chinese manufacturers have improved significantly in recent years, and many now produce flanges that meet international standards such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO).

Moreover, one must note that the Chinese flange industry offers competitive pricing as it benefits from significant cost savings in labor, raw material costs, and streamlined production processes. While the price may be a primary factor for some customers, it is essential to ensure that the quality of the products is not compromised. Therefore, customers must evaluate the quality standards of the products they intend to purchase, regardless of their country of origin.

III. Factors affecting the price and quality of Chinese flanges

There are several factors affecting the price and quality of Chinese flanges. One of the most significant factors is the cost-benefit analysis of production factors such as labor, raw materials, and technology.

In terms of labor, China is an emerging market with lower labor costs compared to more developed countries. This cost advantage provides Chinese manufacturing companies the ability to produce products at a lower cost, which contributes to lower pricing for their products. However, cheaper labor costs may affect the quality of products if manufacturers cut corners in the production process to reduce costs.

In addition to labor, the cost of raw materials also plays a crucial role in the production cost of Chinese flanges. China is abundant in natural resources such as steel, copper, and iron, which are used in the production of flanges. The lower cost of obtaining raw materials translates to cheaper production costs and ultimately results in a lower price for the finished goods.

Lastly, technological advancement and industrial automation also play a significant role in the cost-benefit analysis of Chinese flange production. With the widespread application of technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM), Chinese manufacturers are increasingly capable of producing high-quality products in a shorter time frame. The use of automation further reduces the cost of labor, improves efficiency, and leads to higher-quality products.

Regarding the production process and quality control standards, Chinese flange manufacturers have come a long way in recent years. While concerns over product quality and regulatory compliance have previously been an issue in China, most manufacturers have begun to put in place stringent quality control measures and safety standards. Such measures include extensive product testing, compliance with global quality standards, and certification from independent third-party organizations.

In summary, while factors such as labor, raw materials, and technology contribute to the competitiveness of Chinese flanges’ pricing, quality control measures taken by Chinese manufacturers play a crucial role in ensuring the products’ quality meets global standards. Customers should conduct due diligence when assessing the quality of products they intend to purchase.

IV. The quality guarantee of Yanhao

Yanhao Pipeline Equipment Co., Ltd. is a Chinese flange manufacturer specializing in the production of high-quality industrial pipeline components such as flanges, fittings, and valves. We have been in operation for more than 5 years, and our products are exported globally, serving customers in industries such as oil and gas, petrochemical, and power generation.

At Yanhao, we prioritize quality control and have implemented several measures to ensure we meet or exceed international quality standards. These measures include:

- Strict supplier selection: We select our raw material suppliers carefully and create long-term partnerships with them to ensure consistent quality.

- Extensive product testing: Our products undergo rigorous testing in specialized laboratories to ensure they meet the required safety and quality standards. All tests are carried out based on our customers’ specifications and international standards.

- Certification: We have obtained international certifications such as ISO, CE, API, and ASME, which demonstrate our commitment to quality standards.

- Product traceability: Our products are traceable from raw materials to the finished product. We keep detailed records of the manufacturing process and maintain records of all tests carried out.

Our commitment to quality control has resulted in positive feedback and satisfied customers. Here are some of the testimonials we have received:

- “The quality of their products is unmatched. We have been using Yanhao flanges on our projects for years, and they never disappoint.” – John Smith, Project Manager, Oil, and Gas Company.

- “Yanhao’s customer service is excellent. They are always willing to help and provide prompt responses to our inquiries.” – Jane Doe, Purchasing Manager, Chemical Company.

- “The flanges we received from Yanhao were of excellent quality, and their delivery was prompt. We highly recommend their products.” – David Lee, Project Engineer, Power Generation Company.

In conclusion, Yanhao Pipeline Equipment Co., Ltd. is committed to providing high-quality, cost-effective products. Our focus on quality control has yielded positive results, as evidenced by our certifications and testimonials. We continue to strive for excellence in our products and services and look forward to serving our customers’ needs for years to come.

V. Conclusion

In conclusion, the Chinese flange industry has experienced significant growth in recent years, attributed to the country’s booming industrial sector. Chinese manufacturers have improved significantly in producing flanges that meet international standards while offering competitive pricing.

Key points to note include understanding the factors that affect the pricing and quality of Chinese flanges, examining the production process and quality control standards of Chinese manufacturers, and seeking testimonials and feedback from satisfied customers.

Yanhao Pipeline Equipment Co., Ltd. is an example of a Chinese manufacturer that prioritizes product quality and has implemented measures to ensure consistency in its products. Their focus on quality control has resulted in positive testimonials from satisfied customers, including rigorous product testing, certification, and traceability.

In the future, the Chinese flange industry’s growth prospects remain bright, with increasing demand for energy and rapid industrialization. We advise customers seeking quality Chinese flanges to conduct due diligence, evaluate the quality standards of the products they intend to purchase, and invest in long-term partnerships with reputable manufacturers.

In conclusion, we encourage customers to consider Yanhao Pipeline Equipment Co., Ltd. for their flange manufacturing needs and other reputable manufacturers in the industry. Choosing quality suppliers helps to ensure consistency in product quality and long-term reliability, thus contributing to sustainable business growth.

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.