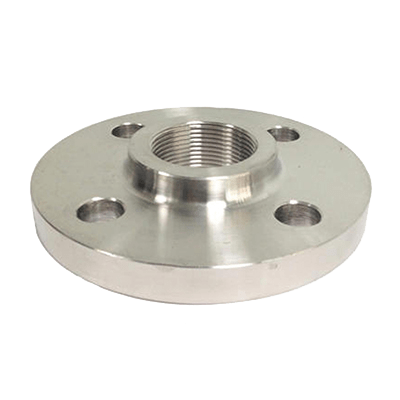

Threaded Flanges

China Threaded Flanges Supplier

We provide flange products of various standards, such as ASME/ANSI B16.5, EN, DIN, JIS standards, etc. We also provide customized threaded flange products.

As a company with 25 years of flange production experience, we support all types of flanges, and we can give you the best product quality, the most reasonable price.

Please enjoy a copy of our online fashion catalog:

Threaded Flange Specifications

| Standard | Type | Class | Size |

|---|---|---|---|

| ASME B16.5 | WN/LWN/SO/Blind/Lap Joint | 150#-2500# | 1/2″-24″ |

| ASME B16.47 Series A | WN/blind flange | 150# -900# | 22″-60″ |

| ASME B16.47 Series B | WN/blind flange | 75# 400# 600# | 26″-60″ |

| 900# | 26″-48″ | ||

| EN1092-1:2002 | Plate flange for welding/loose plate | PN2.5-PN100 | DN10-DN4000 |

| flange with weld-on plate collar or | |||

| for lapped pipe end/Blind/WN flange | |||

| JIS B2220 | Welding Flange, Lap joint flange, threaded flange | PN6-PN100 | DN10-DN1500 |

| BS4504 BS10 TableD/E | Plate Flange for welding/WN flange/Blank Flange | PN6-PN100 | DN10-DN1500 |

| Sealing Surface | RF, FF, MFM, TG, RJ | ||

| Coating | Vanish, yellow paint, anti-rust oil, galvanizing etc | ||

Threaded Flange Materials & Grades

Threaded flanges are available in a variety of materials. These materials must meet the standards. The material should also meet the quality specified by ASTM or ASME standards. The thickness and inner diameter of the flange depend on the size of the pipe for which this Threaded flange is manufactured.

Carbon steel flanges are commonly used manufacturing materials for Threaded flanges. You can choose the appropriate material according to the medium of the pipeline. You can choose ASTM A105 for normal temperature, ASTM A350 for low temperature, and ASTM A694 for high temperature.

Flanges are available in a variety of grades, such as ASME B16 5, ASME B16 47 “A” series and “B” series to meet the needs of customers and industries.

In addition to this material, Threaded flanges are also available in stainless steel and alloy steel, which have material properties such as corrosion resistance, high temperature resistance, and wear resistance. At the same time, we also have duplex steel materials to meet the technical requirements of various pipelines of customers. The following table shows the grades of these common materials:

| Material | Grade |

|---|---|

| Carbon Steel | ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70 |

| Alloy Steel | ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ; |

| Stainless Steel | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| Duplex and Super Duplex | ASTM/ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61, S31803, S32205, S32550, S31254, SMO254, S32750, S32760, S32950 |

| Nickel Alloy Steel | ASTM/ASME B/SB151 UNS N07060, 71500, C70600 (CuNi 90/10), C71500 (CuNi 70/30) |

| UNS N08825( INCOLOY 825), UNS N06600(INCONEL 600), UNS N06601(INCONEL 601), | |

| UNS N06625(INCONEL 625), UNS N10276(HASTELLOY C276) | |

| ASTM/ASME B/SB151 UNS N07060, 71500, C70600 (CuNi 90/10), C71500(CuNi 70/30) | |

| Copper Alloy | ASTM/ASME B/SB151 UNS N07060, 71500, C70600 (CuNi 90/10), C71500 (CuNi 70/30) |

| Titanium | ASTM/ASME B/SB381 Grade 2, Grade 5, Grade 7 |

Threaded Flanges Dimensions

Below we have listed some sizes of Threaded Flanges (Class 150) under ASME B16.5 (1/2″ to 24″)

- 1/2″ NPS flange with 1/2″ NPT threads has an outer diameter of 3.50″. The raised face thickness is 0.62″ and has 4 bolt holes.

- 3/4″ NPS flange with 3/4″ NPT threads has an outer diameter of 3.88″. The raised face thickness is 0.62″ with 4 bolt holes.

- 1″ NPS flange with 1″ NPT threads has an outer diameter of 4.25″. The raised face thickness is 0.68″ and the standard bolt holes are 4 numbers.

- 2″ NPS flange with 2″ NPT threads has an outer diameter of 6.00″. The raised face thickness is 1.00″ and the flange has 4 bolt holes.

- 5″ NPS flange with 5″ NPT threads has an outer diameter of 10.00″. The raised face thickness is 1.44″, and it has 8 bolt holes.

- 6″ NPS flange with 6″ NPT threads has an outer diameter of 11.00″. The raised face thickness is 1.56″, and it has 8 bolt holes.

- 10″ NPS flange with 10″ NPT threads has an outer diameter of 16.00″. The raised face thickness is 1.94″, and it has 12 bolt holes.

- 20″ NPS flange with 20″ NPT threads has an outer diameter of 27.50″. The raised face thickness is 2.87″, and it has 20 bolt holes.

- 24″ NPS flange with 24″ NPT threads has an outer diameter of 32.00″. The raised face thickness is 3.23″, and it has 20 bolt holes.

Standardized Threaded Flanges

- Threaded Flanges are commonly standardized as ASME B16.5, with sizes ranging from 1/2 inch to 60 inches.

- Sealing surface types include raised face (RF), flat face (FF), dimpled face (MFM), tongue and groove (TG), ring joint (RJ), and so on.

- Applicable pressure classes include Class 150, 300, 400, 600, 900, 1500.

| ASME B16.5 Threaded Flanges | |

| Class 150 | Class 600 |

| Class 300 | Class 900 |

| Class 400 | Class 1500 |

Customized Threaded Flanges Process

The following options are for you to customize. If you don’t have a design drawing, you can also consult our engineers and let us help you draw it.

size

Specified pipeline size, including flange ID and OD, thickness, bolt hole diameter, bolt hole distance, etc.

Material

Using specified material suitable for pipeline engineering according to your requirements.

Shape

can be customized with irregular flanges such as square flanges and conical flanges, etc.

Connection

Threaded connection, welding connection, socket welding connection, etc., which can be selected.

Special Treatment

Special treatments such as surface coatings and anti-corrosion can be made according to your needs.

The customization process for flanges is generally as follows:

requirements

Confirmation

Communicate in detail to determine the requirements for flange size, material, pressure, connection method, etc.

Design drawings

Our professional engineers will design flange drawings for you. The drawings will specify the size, shape, thickness, etc. of the flange in detail.

Choose materials

Select suitable flange materials according to the requirements of the engineering project.

Customer confirmation

Send detailed information, such as the designed drawings and materials, to the customer for confirmation.

Processing sample

To ensure accuracy, first produce a sample according to the drawings and selected materials and send it to the customer for trial confirmation.

Production of bulk goods

After confirming the accuracy of the samples, proceed with mass production.

More reading:

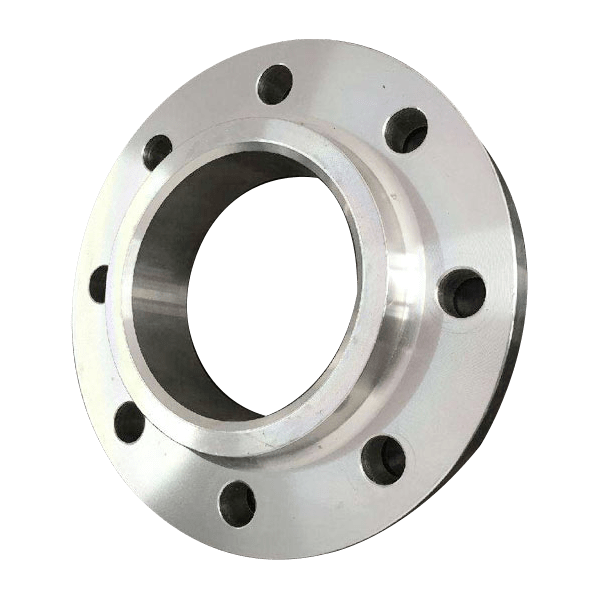

Image Gallery

Here are various Threaded flanges produced by YANHAO. You can click on the pictures to enlarge them. As a company with 25 years of flange production experience, YANHAO supports all types of flange production.

Threaded Flange Product Image Gallery

FAQs About Threaded Flange

About YANHAO

YANHAO is a China Flange Manufacturer located in Hebei Province, China. It is one of the few professional Flange suppliers in China.

We have many years of experience in flange production and have multiple flange production lines. We have sufficient stock of raw materials, rich inventory, fast delivery, and can ship within three days. At the same time, the price is affordable. You are welcome to consult and purchase!

In addition, we can provide a variety of customized flanges and pipe fittings. Customers can give drawings or samples, and our company will produce them to fit your specific requirements.

Our company was founded in 2000 and has more than 300+ employees, including 85+ middle and senior engineering and technical personnel. Our company has several production lines and covers an area of 150,000 square meters and a building area of 30,000 square meters.

300+

Number Of Workers

85+

Mid&Senior Engineers

150,000

Square Meters of Area

25+

Years of Experience

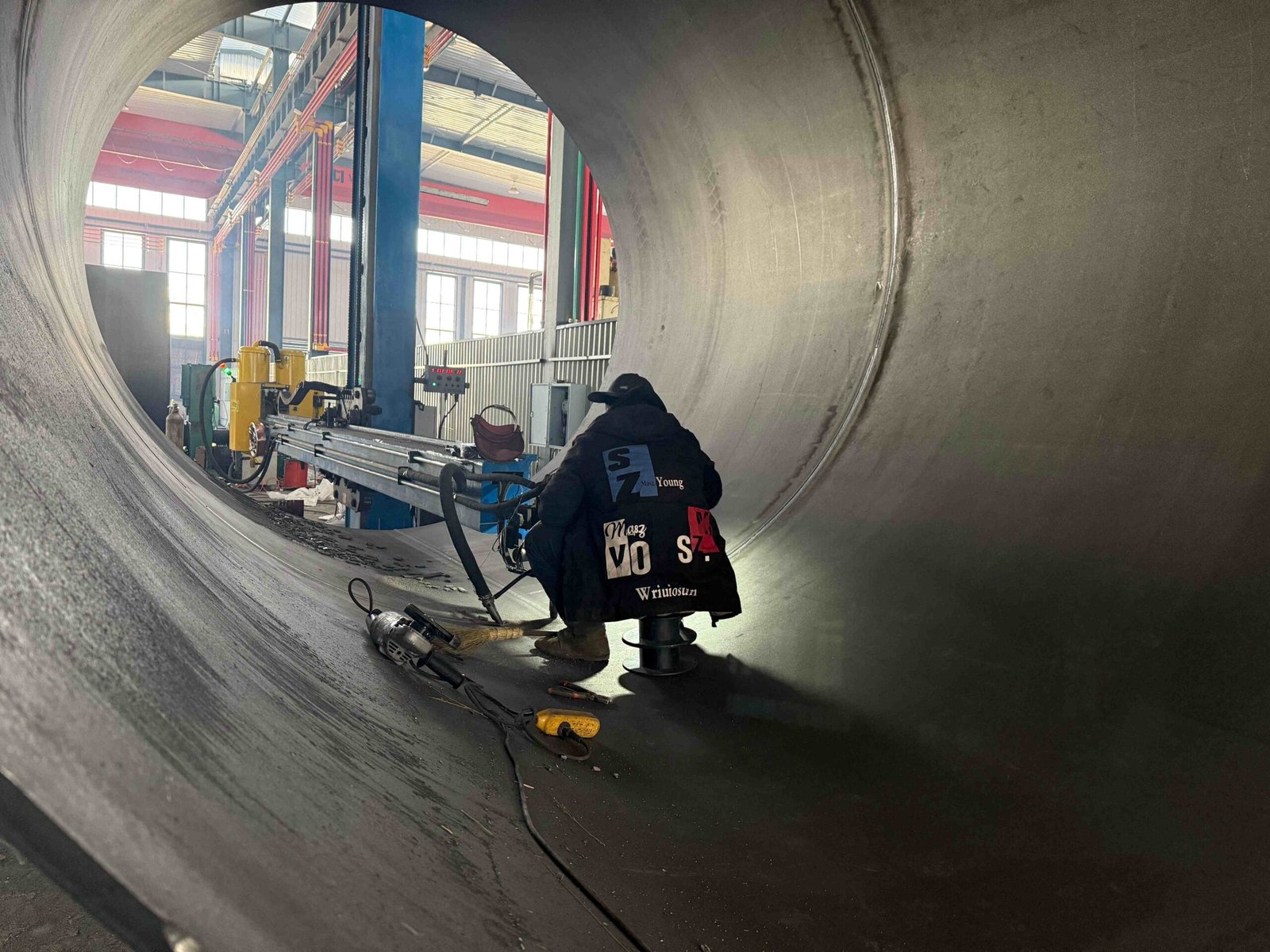

Our Production Line

Our company has 8 pipe fitting production lines and 5 flange production lines. It has a full set of medium-frequency elbow hot-pushing machines, hot-die presses for reducers, cold-extrusion hydraulic presses for tees, forging hammers, vertical lathes, drilling machines, and other process-forming and mechanical processing equipment.

Among them, the Φ1020 mm large-diameter medium-frequency hydraulic pushing machine, Φ1420 mm large-diameter medium-frequency bending machine, and Φ2438 mm 4,000-ton large hot-die press have an annual production capacity of more than 80,000 tons.

8

Pipe Fitting Production Lines

5

Flange Production Lines

80,000 tons

Annual Production Capacity

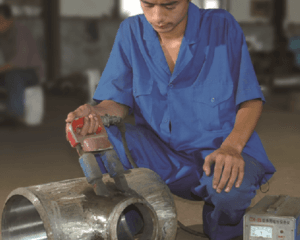

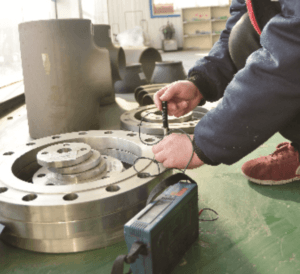

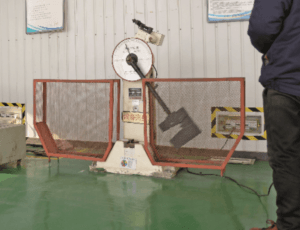

Quality Testing & Certificates

Our company is also equipped with a full set of physical and chemical testing, including spectrometer direct reading, non-destructive testing, heat treatment, water pressure testing, and other product quality testing equipment, providing a reliable guarantee for the production of high-quality products.

FAQs

More Types of Flanges

Weld Neck Flanges (WN)

WN flange, also known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, the rim, is fitted around the circumference.

China welding neck flange products >>

Slip-on Flanges (SO)

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

China slip-on flange products >>

Socket Weld Flanges (SW)

Socket Weld Flanges (SW) are similar to Slip-on Flanges (SO). The difference is that there is an extra piece in the middle.

China socket weld flange products >>

Blind Flanges (BF)

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints.

China blind flange products >>

Lap joint flange (LJ)

Consisting of two components: a stub end and a lap joint ring flange. The respective stub end is slid into the flange’s bore, and the stub end is joined to the pipe through butt welding.

China lap joint flange products >>

Threaded Flanges (TF)

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe. The installation does not involve welding

China threaded flange products >>