Pipe Tee

Our company provides All Kinds of Pipe Tee

We provide pipe tee products of various standards, such as American standards, European standards, German standards, and Japanese standards. The list of common standards is as follows:

lewis Liu

Sales Manager

Pipe Tee could be ranged from Diameter, connection types, material types.

Classified by Diameter

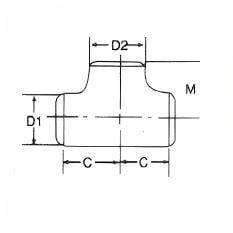

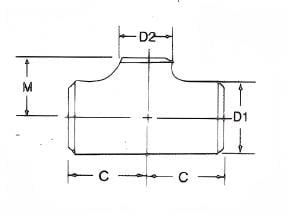

Pipe tees are mainly divided into two types according to the branch diameter: equal-diameter tees and reducing tees. Equal-diameter tees refer to the nominal diameters of the main pipe and the branch pipe being the same (such as NPS 4″×4″×4″); reducing tees refer to the branch diameter being smaller than the main pipe (such as NPS 4″×4″×3″). Its structure and size design must strictly follow international standards such as ASME B16.9 and MSS SP-43 to ensure installation compatibility and sealing stability under high pressure and complex working conditions.

In addition, the manufacturing standard of the tee not only requires matching of the nominal diameter, but also sets tolerance limits on the center-to-end dimension (C/M) to ensure that the tee can achieve precise structural docking and minimize flow resistance during system assembly. Equal-diameter and reducing tees cover a wide range of sizes, with standard specifications from ½″ to 48″, and are commonly used in various industrial pipelines such as petrochemical, power, shipbuilding, and HVAC.

equal-diameter tees

Equal Tee is a T-shaped pipe fitting with the same diameter as the main pipe. Equal Tee can be divided into straight-through tees (the branch pipe is at right angles to the main pipe) or transverse tees (the branch pipe is at other angles to the main pipe), of which the straight-through type is the most common. The three ends of the pipe fitting are butt-welded to the pipeline system to form a three-way branch or confluence connection. Common materials include carbon steel (ASTM A234 WPB) and stainless steel (ASTM A403 WP304/316L).

Reducing tee

Reducing tee is a T-shaped butt-weld fitting with a branch outlet with a smaller nominal pipe diameter than the two pipe outlets. Unlike a equal-diameter tee, one of the branches tapers in diameter, allowing flow to be divided or combined while reducing pipe size without adding a separate reducer and tee assembly. For example, 4×4×3 represents a reducing tee with two 4-inch pipe ends and a 3-inch branch. Commonly used for pressure gauges, sampling lines

Weights are from stainless‑steel‑fitting.com’s ASME B16.9 chart (SCH 10S/40S/80S)

Classified by Connection Types

As per the connection mode, Pipe Tee could be classified by Butt Weld Tee, Socket Weld Tee and Threaded Tee.

Classified by Connection Types

According to the valve body material, it has stainless steel, carbon steel and alloy steel Tee.

Stainless Steel tee

Material Characteristics: Excellent corrosion resistance, hygienic properties, and oxidation resistance. Maintains mechanical properties at high/low temperatures.

| Subtype | Standard & Grade | Key Advantages | Application Directions |

|---|---|---|---|

| Austenitic | ASTM A403 WP304/L | • 18% Cr-8% Ni composition • Cost-effective corrosion resistance • Easy fabrication | • Food processing pipelines (sanitary requirements) • Architectural water features (SCH10S thin-wall) • Weak acid chemical transport (pH 3-6) |

| Austenitic (Mo-Added) | ASTM A403 WP316/L | • 2-3% Mo addition • Superior chloride resistance • Non-magnetic properties | • Seawater cooling systems (power plants) • Pharmaceutical bioreactors (electropolished) • Coastal chemical plants |

| Duplex | ASTM A815 S31803 (2205) | • 22% Cr-5% Ni-3% Mo • 2x strength of 304SS • Stress corrosion cracking resistance | • Subsea pipeline tie-ins • Sour gas processing (H₂S >50ppm) • Desalination plant high-pressure lines |

| Super Duplex | ASTM A815 S32750 (2507) | • 25% Cr-7% Ni-4% Mo • PREN ≥42 • Extreme pitting/erosion resistance | • FGD scrubber circulation loops • Offshore topside piping • Geothermal brine systems (high chloride) |

Carbon Steel tee

Material Characteristics: Cost-effective, excellent weldability, and reliable mechanical strength. Limited corrosion resistance requires protective coatings.

| Subtype | Standard & Grade | Key Advantages | Application Directions |

|---|---|---|---|

| General Purpose | ASTM A234 WPB | • Yield ≥240 MPa • -29°C to 425°C service • Low carbon content (0.3% max) | • Building HVAC systems (SCH40) • Low-pressure oil pipelines (Class 150) • Fire protection water lines |

| Low-Temperature | ASTM A420 WPL6 | • Charpy impact ≥20J @ -46°C • Fine-grain structure • MSS SP-75 compliant | • LNG transfer arms (-162°C) • Cryogenic storage facilities • Arctic oil pipelines (NACE MR0175) |

| High-Strength | ASTM A860 WPHY 60/65 | • Yield ≥415-450 MPa • Fatigue resistance • Optimized for welding | • Hydraulic fracturing manifolds • Mining slurry transport (SCH160) • Bridge compressed air systems |

Alloy Steel tee

Material Characteristics: Enhanced high-temperature strength, creep resistance, and specialized chemical properties. Requires controlled welding procedures.

| Subtype | Standard & Grade | Key Advantages | Application Directions |

|---|---|---|---|

| Cr-Mo Alloy | ASTM A234 WP11/WP22 | • 1.25% Cr-0.5% Mo • Creep resistance ≤540°C • Hydrogen attack resistance | • Refinery catalytic reformers • Medium-temperature steam lines (300-540°C) • Hydrogen generation plants |

| High-Chromium | ASTM A234 WP91 | • 9% Cr-1% Mo-V-Nb • Creep resistance ≤650°C • ASME Sec VIII compliance | • Ultra-supercritical boilers • Nuclear reactor feedwater systems • Biomass gasification reactors |

| Nickel Alloy | ASTM B366 N06625 | • 58% Ni-22% Cr-9% Mo • Acid corrosion resistance • Oxidation resistance @ 1100°C | • Flue gas desulfurization ducts • Chemical reactor agitators • Sulfuric acid concentrators |

Material Selection Guide

| Service Condition | Recommended Material | Critical Standard |

|---|---|---|

| Seawater immersion | S32750 (2507) | ASTM A815 |

| -100°C cryogenic | WPL6 | MSS SP-75 |

| 600°C steam | WP91 | ASME B16.25 |

| H₂S sour gas (>50ppm) | S31803 (2205) | NACE MR0175 |

| High-pressure hydrogen (90MPa) | WPHY 65 | ASME B31.12 |

Design Tip: For cyclic service (e.g., pump discharge), specify seamless elbows with NDE (UT/RT) per ASME B16.9 Appendix V.

Customized Pipe tee Process

The following options are for you to customize. If you don’t have a design drawing, you can also consult our engineers and let us help you draw it.

size

Specified pipeline size, including pipe elbow direction angle, thickness, bolt hole diameter, bolt hole distance, etc.

Material

Using specified material suitable for pipeline engineering according to your requirements.

Shape

can be customized with pipe Tee such as Reducing Elbow.

Connection

Butt Weld Tee, Socket Weld Tee, Threaded Tee, etc., which can be selected.

Special Treatment

Special treatments such as surface coatings and anti-corrosion can be made according to your needs.

The customization process for Pipe Tee is generally as follows:

requirements

Confirmation

Communicate in detail to determine the requirements for pipe elbow size, material, pressure, connection method, etc.

Raw Material Preparation

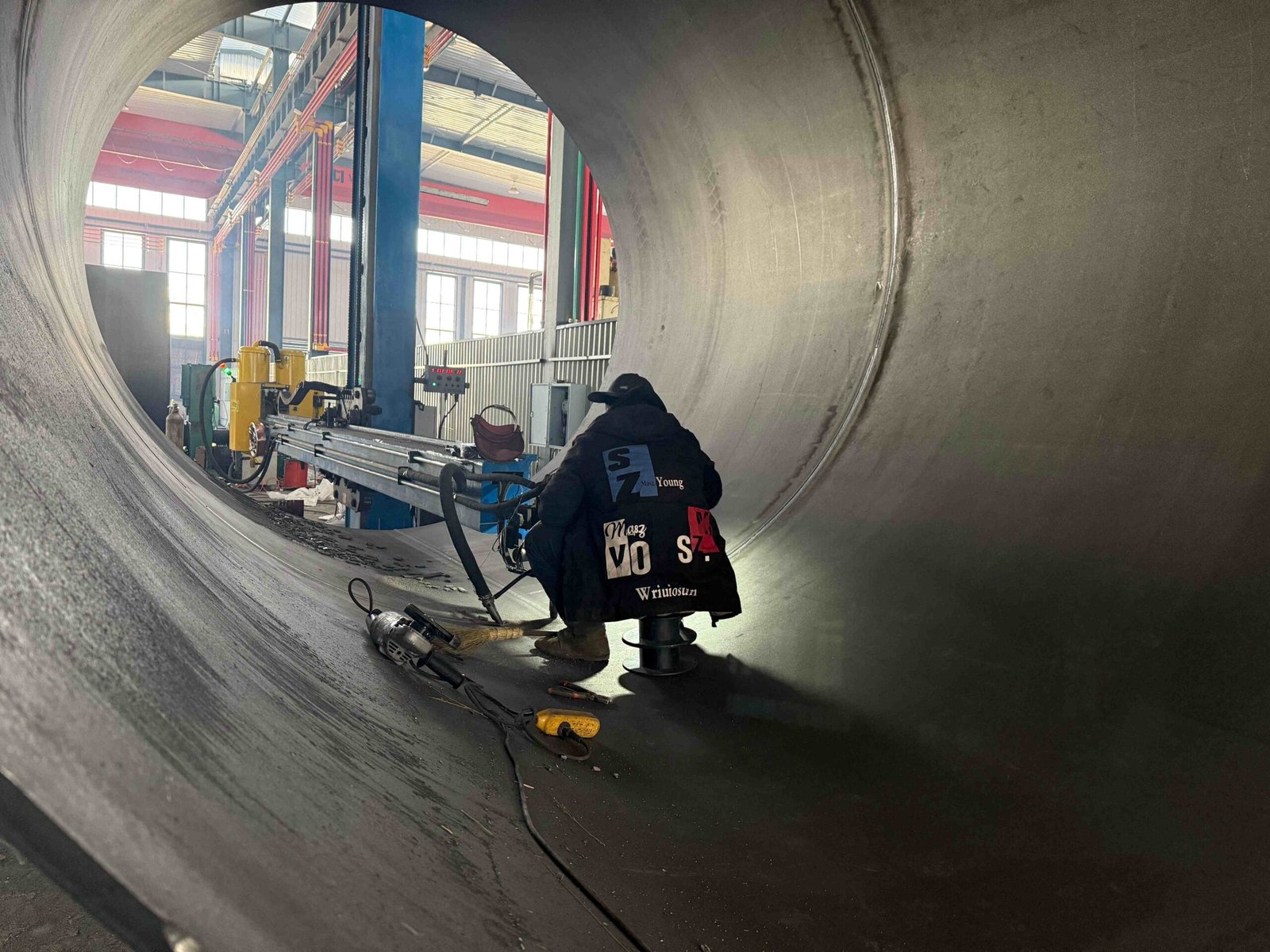

Cut pipe to dimensions on process card using CNC cutting machines (±1mm tolerance). Remove burrs, scale, and debris from cut ends. Grind pipe ends smooth.

Billet Pre-Treatment

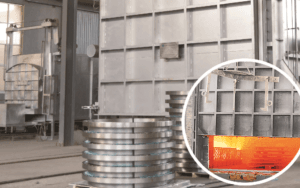

Spray internal coating lead powder graphite binder solution 0.2-0.3mm thickness dry in 120C oven for two hours

Hot Push Bending

Install mandrel die heat tube via medium-frequency induction to 750±10C hydraulic push at 50-80mms with 300-500t force

Post Forming Processing

Cool via air mist mixture control 50-80Cmin rate lathe machine ends ensure wall uniformity bevel 375±25deg

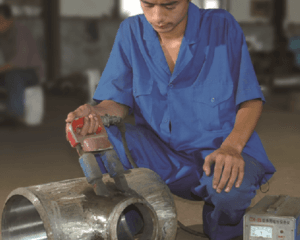

Quality Inspection

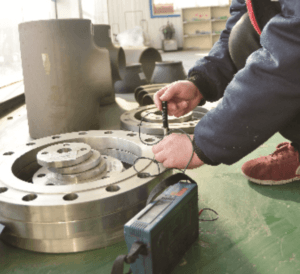

Check surface defects verify dimensions with calibrated gauges perform 100 percent MT and UT nondestructive testing

Surface Treatment

Shot blast using cast steel shot achieve SA25 cleanliness apply epoxy primer and polyurethane topcoat at specified thickness

Packaging Storage

Protect ends with plastic caps separate elbows with foam spacers include certificates store in dry ventilated warehouse

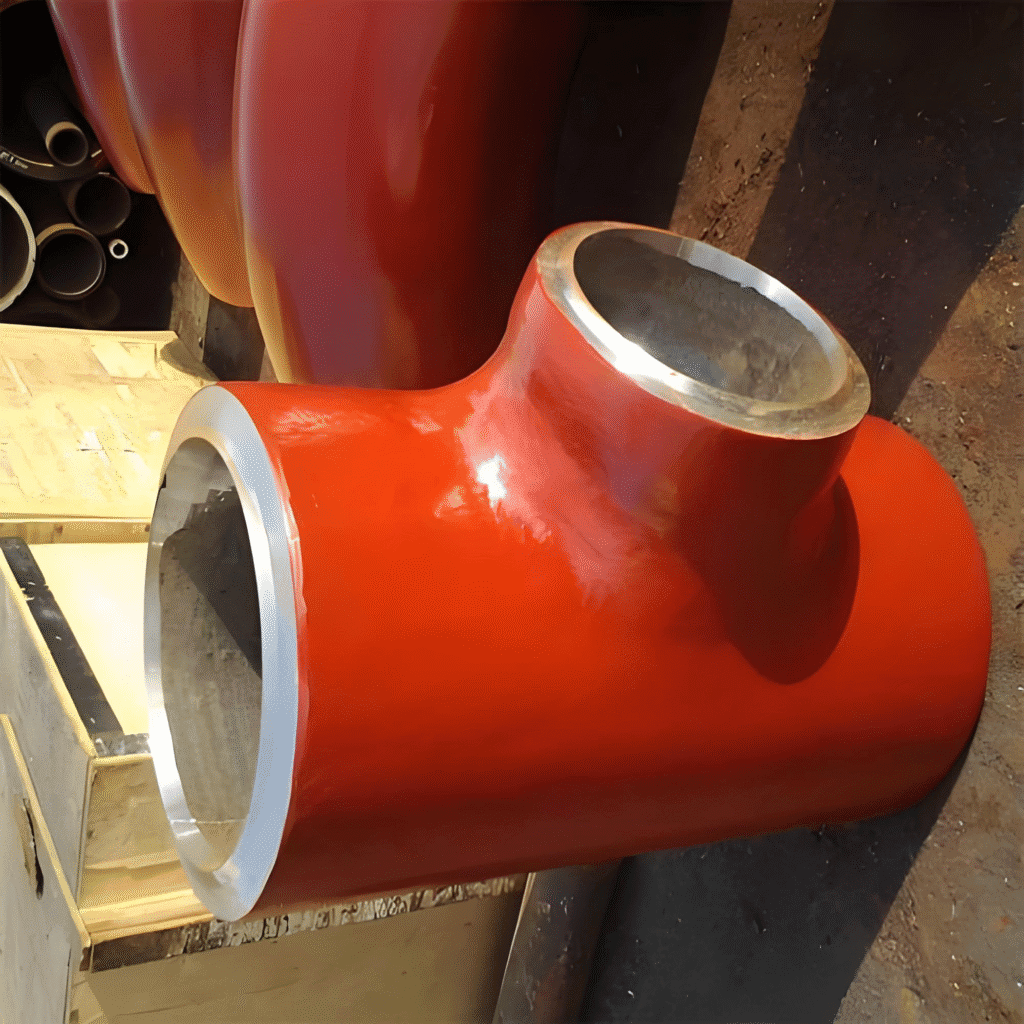

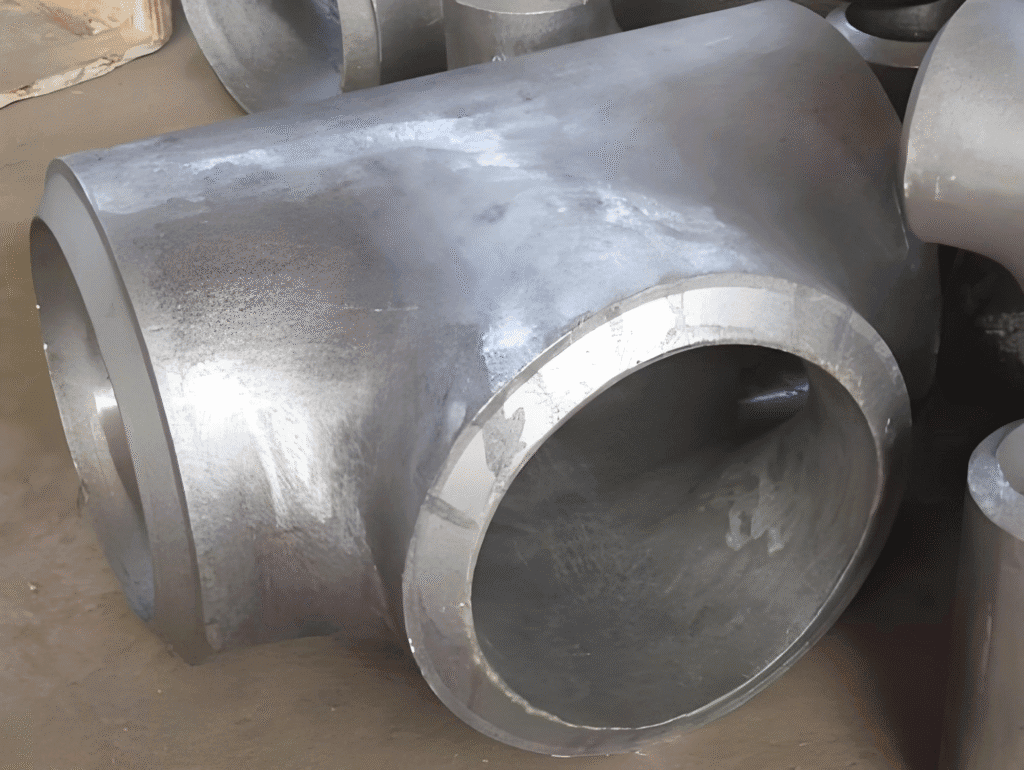

Image Gallery

Here are various Pipe Tee produced by YANHAO. You can click on the pictures to enlarge them. As a company with 25 years of Pipe Tee production experience, YANHAO supports all types of Pipe Tee production.

Pipe Tee Image Gallery

FAQs About Pipe Tee

About YANHAO

YANHAO is a China Flange Manufacturer located in Hebei Province, China. It is one of the few professional Flange suppliers in China.

We have many years of experience in flange production and have multiple flange production lines. We have sufficient stock of raw materials, rich inventory, fast delivery, and can ship within three days. At the same time, the price is affordable. You are welcome to consult and purchase!

In addition, we can provide a variety of customized flanges and pipe fittings. Customers can give drawings or samples, and our company will produce them to fit your specific requirements.

Our company was founded in 2000 and has more than 300+ employees, including 85+ middle and senior engineering and technical personnel. Our company has several production lines and covers an area of 150,000 square meters and a building area of 30,000 square meters.

300+

Number Of Workers

85+

Mid&Senior Engineers

150,000

Square Meters of Area

25+

Years of Experience

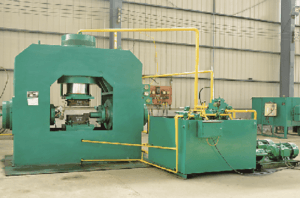

Our Production Line

Our company has 8 pipe fitting production lines and 5 flange production lines. It has a full set of medium-frequency elbow hot-pushing machines, hot-die presses for reducers, cold-extrusion hydraulic presses for tees, forging hammers, vertical lathes, drilling machines, and other process-forming and mechanical processing equipment.

Among them, the Φ1020 mm large-diameter medium-frequency hydraulic pushing machine, Φ1420 mm large-diameter medium-frequency bending machine, and Φ2438 mm 4,000-ton large hot-die press have an annual production capacity of more than 80,000 tons.

8

Pipe Fitting Production Lines

5

Flange Production Lines

80,000 tons

Annual Production Capacity

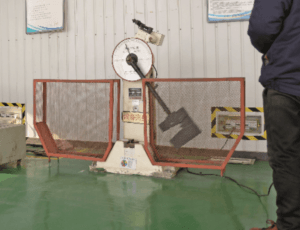

Quality Testing & Certificates

Our company is also equipped with a full set of physical and chemical testing, including spectrometer direct reading, non-destructive testing, heat treatment, water pressure testing, and other product quality testing equipment, providing a reliable guarantee for the production of high-quality products.