Pipe Reducer

Our company provides All Kinds of Pipe Reducer

We provide Pipe Reducer products of various standards, such as American standards, European standards, German standards, and Japanese standards. The list of common standards is as follows:

lewis Liu

Sales Manager

Reducers can be categorized as seamless, welded, and butt-welded. They can be categorized as concentric or eccentric, and commonly used materials include carbon steel, stainless steel, and alloy steel. By standard, they can be categorized as national, Ministry of Chemical Industry, power plant, shipbuilding, American, European, Russian, German, and Japanese. Common forming processes include reducing, expanding, or both. Stamping can also be used for some reducer sizes.

Classified by Shape types

Concentric reducers

Concentric reducers feature a symmetrical conical structure, with both ends and the midpoint located on the same centerline. They are suitable for connecting vertical pipes of varying diameters or for systems where horizontal alignment is not necessary.

The smooth transition of fluid along the tapered channel effectively reduces turbulence and pressure drop, making them suitable for applications such as chemical, oil and gas, and water treatment, where center alignment and uniform flow rates are crucial. Their manufacturing process is relatively simple and cost-effective.

eccentric reducer

Eccentric reducer has one flat side and one tapered side, with misaligned centerlines. It can be installed with the flat side facing up or down to prevent liquid or air accumulation. With the flat side facing up, it’s ideal for horizontal liquid flow, preventing air pockets at the top of the pipe. With the flat side facing down, it’s suitable for steam or aerated systems, facilitating drainage and supporting pipe racks.

Eccentric reducers are suitable for pump inlets and horizontal pipelines, stabilizing suction performance and preventing cavitation. However, due to their slightly more complex manufacturing and strict installation orientation requirements, they are slightly more expensive than concentric reducers.

Classified by Connection Types

As per the connection mode, Pipe Reducer could be classified by Butt Weld, Socket Weld and Threaded.

Classified by Material Types

According to the valve body material, it has stainless steel, carbon steel and alloy steel elbow.

Stainless Steel pipe Reducer

| Subtype & Grade | Description | Key Features | Applications | Standards |

|---|---|---|---|---|

| Austenitic (WP304 / WP304L) | Reducers made from ASTM A403 WP304 / WP304L stainless steel; available in seamless or weld‑built concentric/eccentric types | Good general corrosion resistance; excellent weldability and formability; cost‑effective for non‑chloride environments | General chemical processing, potable water, food & beverage, HVAC, architecture, light industrial piping | ASTM A403 WP304 / WP304L; manufactured per ASME B16.9 (dimensions) & B16.25 (butt‑weld ends); light fitting per MSS‑SP‑43; marking per MSS‑SP‑25; also available in DIN/JIS versions |

| Austenitic (WP316 / WP316L) | Reducers made from ASTM A403 WP316 / WP316L stainless steel; offered as forged or seamless concentric/eccentric fittings | Superior resistance to chlorides, pitting, and crevice corrosion; retains toughness at low temperatures; suitable for harsher service | Marine environments, pharmaceutical, coastal chemical plants, desalination, chloride‑bearing service | ASTM A403 WP316 / WP316L; ASME B16.9 / B16.25; MSS‑SP‑43; size and schedule per ASME standards (Sch 5S–Sch 160, XXS); threads per ANSI where applicable |

| Duplex Stainless Steel (e.g. 2205) | Reducers made from duplex stainless alloys like UNS S31803 / S32205 (ASTM A815); typically forged concentric or eccentric transitions | High yield and tensile strength; excellent resistance to stress corrosion cracking and chloride stress corrosion; lower thermal expansion | Offshore oil & gas, chemical processing, seawater cooling, pulp & paper, high strength corrosive environments | ASTM A815 (duplex fittings); dimensioning per ASME B16.9; marking and light fitting guidance per MSS‑SP‑43; also available under DIN/EN standards |

Carbon Steel pipe reducer

| Grade (ASTM A234) | Description | Features | Applications | Standards |

|---|---|---|---|---|

| WPB / WPC | Butt‑weld reducers (concentric/eccentric), seamless or welded carbon steel fittings | Economical carbon steel; solid weldability; moderate‑temperature strength; widespread use | Oil & gas, water treatment, industrial piping, power plants | ASTM A234 WPB/WPC; ASME B16.9 (dims), B16.25 (ends); MSS‑SP‑43 (light fittings); MSS‑SP‑79/83/95 etc. |

| WP11 (Chrome‑Moly) | Alloy-steel reducer made per ASTM A234 WP11 (CL1/2/3), forged, suited for moderate-high temp use | Higher temperature strength; Cr‑Mo alloying for elevated service; good toughness | High‑temp steam lines, refinery, petrochemical, pressure vessel connection | ASTM A234 WP11; ASME B16.9/B16.11; MSS‑SP‑79/83/95/97 compliance (American Piping Products, |

| WP22 (Chrome‑Moly) | Reducer made from ASTM A234 WP22 alloy steel (1–1.5% Cr, 0.4–0.6% Mo), forged or welded | Excellent creep & corrosion resistance at elevated temperatures; stronger alloy performance | High‑pressure, high‑temperature services: power plants, chemical process lines | ASTM A234 WP22; ASME B16.9; MSS‑SP‑79/83/95; heat‑treated per A960/A960M |

Alloy Steel pipe Reducer

| Grade (ASTM A234) | Description | Features | Applications | Standards |

|---|---|---|---|---|

| WP5 (Cr‑Mo alloy) | Alloy‑steel butt-weld reducers (concentric/eccentric), forged per ASTM A234 WP5 | High-temperature creep resistance; enhanced mechanical properties via Cr‑Mo alloying | High‑temp petrochemical, power generation, refinery steam lines | ASTM A234 WP5; ASME B16.9/B16.11; MSS‑SP‑79/83/95; heat‑treatment per A960/A960M; schedule range SCH5S‑XXS |

| WP9 (9Cr‑Mo alloy) | Reducers per ASTM A234 WP9 (Cr‑Mo), available in concentric/eccentric form | Excellent strength & toughness at elevated temperatures; good general corrosion and SCC resistance | Petroleum, petrochemical, gas, power plants, seawater and chemical processing lines | ASTM A234 WP9; ASME B16.9/B16.25; size range ½″–48″, Sch 5S‑XXS; MSS‑SP‑43, SP‑79; marking and inspection per NACE/3.1B |

| WP11 (Cr‑Mo alloy) | Alloy‑steel reducer per ASTM A234 WP11, concentric or eccentric | Elevated temperature performance; moderate alloying improves creep and corrosion resistance | Refinery, chemical process heating systems, high‑pressure service | ASTM A234 WP11; ASME B16.9/B16.11; MSS‑SP‑79/83/95; similar heat‑treatment requirements |

| WP22 (2Cr‑1Mo alloy) | Reducers made to ASTM A234 WP22 standard for high temp service | Strong creep resistance and mechanical robustness at elevated temperatures | Power plants, chemical process lines, high-pressure/high-temperature systems | ASTM A234 WP22; ASME B16.9; MSS‑SP‑79/83/95; manufacturing per steel pipe fittings specifications |

| WP91 (9Cr‑1Mo alloy) | Alloy reducers per ASTM A234 WP91, forged or seamless | High strength, creep and thermal fatigue resistance; suitable for ultra‑high temperature applications | Heavy-duty power generation, steam boilers, heat exchangers at very high temperatures | ASTM A234 WP91; ASME B16.9; MSS‑SP‑79/83/95; heat treatment per A960/A960M; NPS up to 48″, schedule SCH range up to XXS |

Customized Pipe Reducer Process

The following options are for you to customize. If you don’t have a design drawing, you can also consult our engineers and let us help you draw it.

size

Specified pipeline size, including pipe elbow direction angle, thickness, bolt hole diameter, bolt hole distance, etc.

Material

Using specified material suitable for pipeline engineering according to your requirements.

Shape

can be customized with pipe elbow such as Reducing Elbow.

Connection

Butt Weld Elbows, Socket Weld Elbows, Threaded Elbows, etc., which can be selected.

Special Treatment

Special treatments such as surface coatings and anti-corrosion can be made according to your needs.

The customization process for Pipe Cap is generally as follows:

requirements

Confirmation

Communicate in detail to determine the requirements for pipe elbow size, material, pressure, connection method, etc.

Raw Material Preparation

Cut pipe to dimensions on process card using CNC cutting machines (±1mm tolerance). Remove burrs, scale, and debris from cut ends. Grind pipe ends smooth.

Billet Pre-Treatment

Spray internal coating lead powder graphite binder solution 0.2-0.3mm thickness dry in 120C oven for two hours

Hot Push Bending

Install mandrel die heat tube via medium-frequency induction to 750±10C hydraulic push at 50-80mms with 300-500t force

Post Forming Processing

Cool via air mist mixture control 50-80Cmin rate lathe machine ends ensure wall uniformity bevel 375±25deg

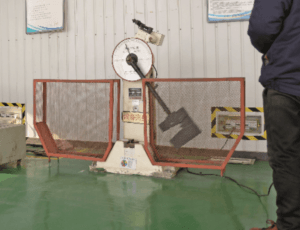

Quality Inspection

Check surface defects verify dimensions with calibrated gauges perform 100 percent MT and UT nondestructive testing

Surface Treatment

Shot blast using cast steel shot achieve SA25 cleanliness apply epoxy primer and polyurethane topcoat at specified thickness

Packaging Storage

Protect ends with plastic caps separate elbows with foam spacers include certificates store in dry ventilated warehouse

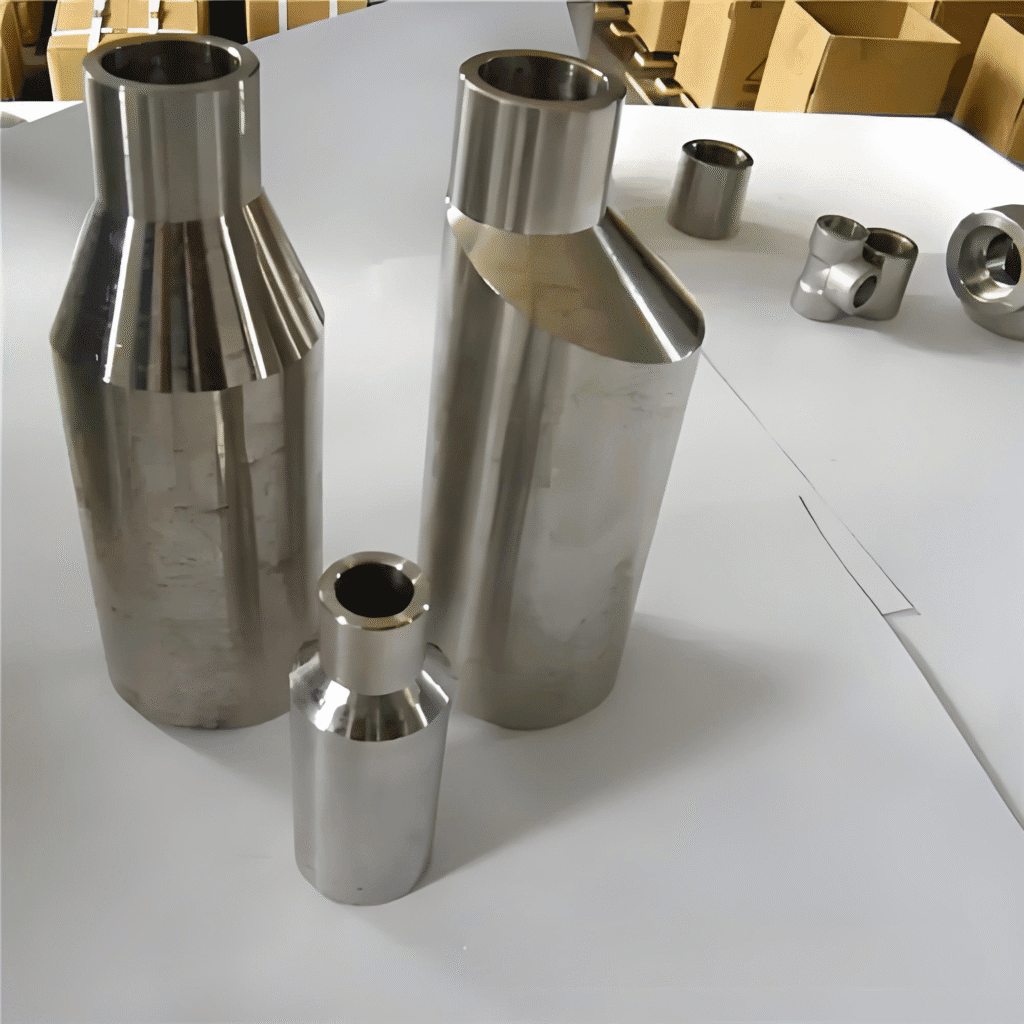

Image Gallery

Here are various Pipe Reducer produced by YANHAO. You can click on the pictures to enlarge them. As a company with 25 years of Pipe Reducer production experience, YANHAO supports all types of Pipe Reducer production.

Pipe Reducer Image Gallery

FAQs About Pipe Reducer

About YANHAO

YANHAO is a China Flange Manufacturer located in Hebei Province, China. It is one of the few professional Flange suppliers in China.

We have many years of experience in flange production and have multiple flange production lines. We have sufficient stock of raw materials, rich inventory, fast delivery, and can ship within three days. At the same time, the price is affordable. You are welcome to consult and purchase!

In addition, we can provide a variety of customized flanges and pipe fittings. Customers can give drawings or samples, and our company will produce them to fit your specific requirements.

Our company was founded in 2000 and has more than 300+ employees, including 85+ middle and senior engineering and technical personnel. Our company has several production lines and covers an area of 150,000 square meters and a building area of 30,000 square meters.

300+

Number Of Workers

85+

Mid&Senior Engineers

150,000

Square Meters of Area

25+

Years of Experience

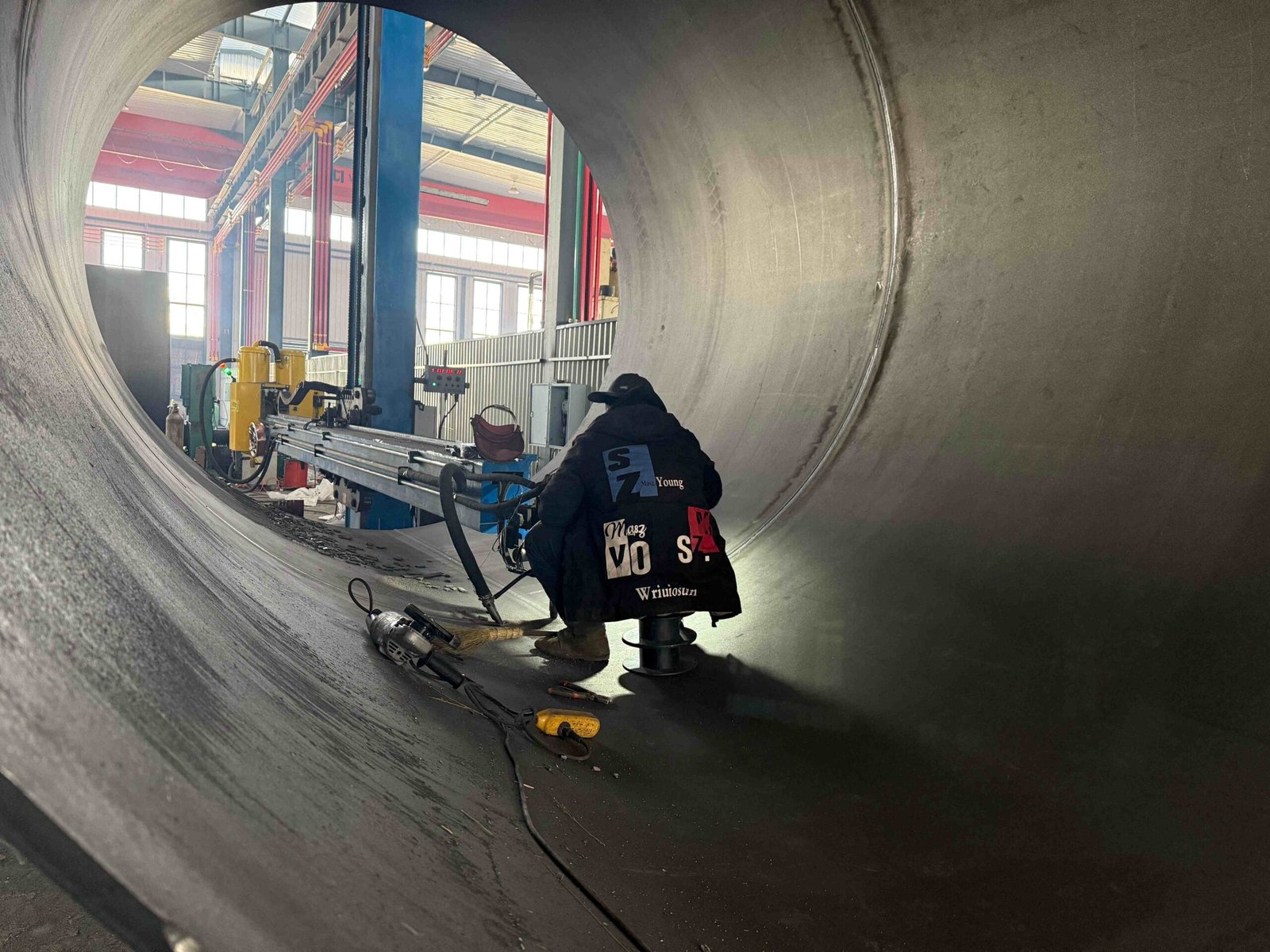

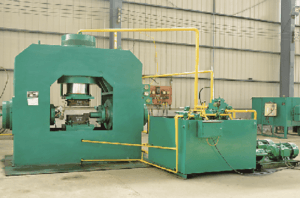

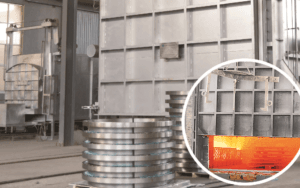

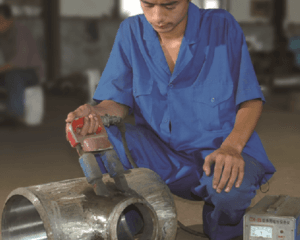

Our Production Line

Our company has 8 pipe fitting production lines and 5 flange production lines. It has a full set of medium-frequency elbow hot-pushing machines, hot-die presses for reducers, cold-extrusion hydraulic presses for tees, forging hammers, vertical lathes, drilling machines, and other process-forming and mechanical processing equipment.

Among them, the Φ1020 mm large-diameter medium-frequency hydraulic pushing machine, Φ1420 mm large-diameter medium-frequency bending machine, and Φ2438 mm 4,000-ton large hot-die press have an annual production capacity of more than 80,000 tons.

8

Pipe Fitting Production Lines

5

Flange Production Lines

80,000 tons

Annual Production Capacity

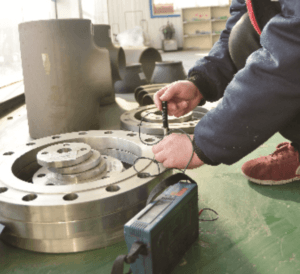

Quality Testing & Certificates

Our company is also equipped with a full set of physical and chemical testing, including spectrometer direct reading, non-destructive testing, heat treatment, water pressure testing, and other product quality testing equipment, providing a reliable guarantee for the production of high-quality products.