Custom Pipe Flanges

YANHAO provides flange customization services. You only need to provide us with your design drawings or specific parameters. If you don’t have these, you can also communicate with us about your project needs and let our engineers help you design. After the design is completed, we also provide sample service.

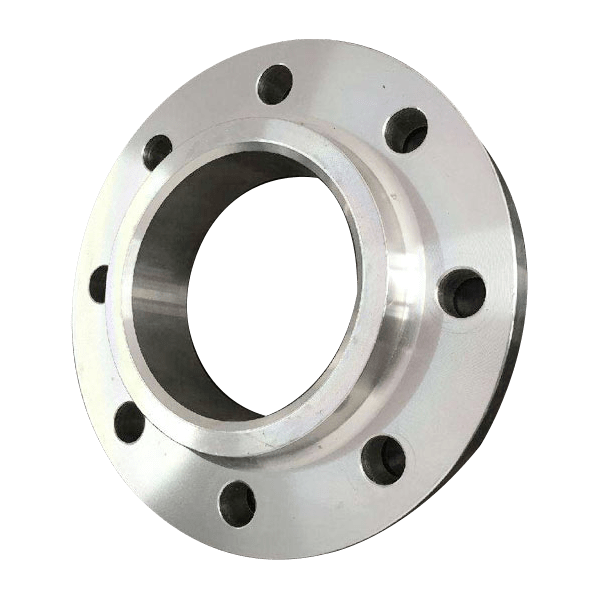

Custom Forged Flanges

YANHAO is a pipe flange manufacturer in China that specializes in customizing metal pipe flanges from 1/2″ to 250″ diameter to your specifications. You provide the specifications and drawings, and YANHAO will deliver your pipe flanges on time.

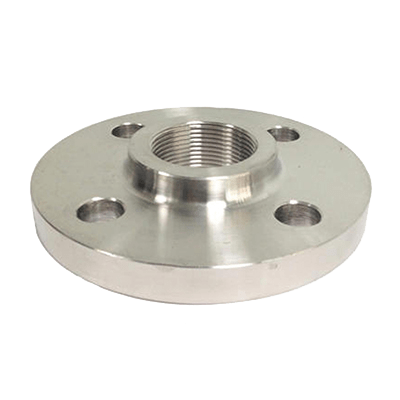

We offer a variety of commonly used custom-forged flanges, which include slip-on pipe flanges, weld neck pipe flanges, blind pipe flanges, lap joints, and threaded pipe flanges. Custom-forged flanges are typically made from a range of materials such as carbon steel, low-temperature steel, stainless steel, nickel alloys, duplex steel, and chrome-molybdenum steel.

YANHAO can customize them or produce them according to standards, 1/2” through 24” B16.5, as well as large diameter flanges 26” through 108” dimensional standards of AWWA, ANSI/ASME B16.47 Series A & B, and Class 125.

If you are looking for a specific type of flange that is suitable for your industrial application, offers high durability, and is of the highest quality, then YANHAO’s industrial flanges are your best choice!

Material Grades And Performance

When manufacturing flanges for industrial use, the choice of material grade becomes a key determinant of strength and service life. You can choose from a range of commercially available materials, each with unique properties:

| Carbon Steel | 1004 – 1080, SA 105, SA 350, LF1, LF2, LF3, LF6, A707, A694 |

| Stainless Steel | 303, 304/L/H, 316/L/H, 310, 317/L, 321/H, 347/H, 410, 416, 420, 440, 17-4, 254 SMO, Nitronic 50®, Nitronic 60®, Duplex & Super Duplex SS, 2205 Duplex, Super Duplex 2507, Zeron 100®, Ferralium 255® |

| Alloy Steel | 4130, 4140, 4330, 4340, 8620, 8630, 9310 |

| Chrome Moly | SA 182, F1, F5, F5A, F9, F11, F12, F22, F22M, F91 |

| Nickel Alloys | 200, 201, Monel 400®, Monel K500®, Inconel 600®, Inconel 617®, Inconel 625®, Inconel 718®, Inconel X750®, Incoloy 800®, Incoloy 825®, Hastelloy C-276®, Hastelloy B2®, Hastelloy B3®, Hastelloy C-22®, 904L, AL6XN |

| Aluminum Alloys | 3003, 6061, 7075 |

| Titanium Alloys | F2, F3, F4, F5, F6, F7 |

What we need to know about custom flange

The following options are for you to customize. If you don’t have a design drawing, you can also consult our engineers and let us help you draw it.

size

Specified pipeline size, including flange ID and OD, thickness, bolt hole diameter, bolt hole distance, etc.

Material

Using specified material suitable for pipeline engineering according to your requirements.

Shape

can be customized with irregular flanges such as square flanges, and conical flanges, etc.

Connection

Threaded connection, welding connection, socket welding connection, etc., which can be selected.

Special Treatment

Special treatments such as surface coatings, anti-corrosion can be made according to your needs.

Even if you don’t know the specific size parameters, you can still communicate with our engineers, and we will help you design the products you need.

Explore Our Flanges

YANHAO boasts a comprehensive range of industrial flanges and fittings by the latest management specifications:

YANHAO offers the best selection of flanges and fittings, perfectly suited for your applications.

Flange customization Workflow

Customizing flanges is to better adapt to pipeline environments and improve pipeline efficiency. YANHAO customized flanges can guarantee 100% matching with existing pipelines. The basic process of customizing flanges at YANHAO is as follows:

requirements

Confirmation

Communicate in detail to determine the requirements for flange size, material, pressure, connection method, etc.

Design drawings

Our professional engineers will design flange drawings for you. The drawings will specify the size, shape, thickness, etc. of the flange in detail.

Choose materials

Select suitable flange materials according to the requirements of the engineering project.

Customer confirmation

Send detailed information, such as the designed drawings and materials, to the customer for confirmation.

Processing sample

To ensure accuracy, first produce a sample according to the drawings and selected materials and send it to the customer for trial confirmation.

Production of bulk goods

After confirming the accuracy of the samples, proceed with mass production.

quality assurance for custom flanges

Customers trust us

YANHAO is 100% confident in the quality of its customized flange products, and the quality is absolutely guaranteed. Because YANHAO is one of the largest pipe fitting manufacturers in China, with 25 years of production experience, more than 400 key customers worldwide, and countless small partners.

Strict quality inspection

At the same time, you can learn here that YANHAO has the most complete quality inspection equipment and personnel. Every product produced by YANHAO will undergo rigorous quality inspection before it is presented to our customers.

Sample: seeing is believing

At the same time, we provide customers with sample services. Only by seeing it can you know how good the quality of YANHAO’s products is. For standard products, we can provide free samples. For customized flange products, we can also provide free samples in some cases. Please communicate with our business for details.

Certificates

You can also check our various qualifications. We have a lot of domestic and international certifications. The following is only a part of it. If you need to check it, please feel free to contact our business personnel.