180-Degree Short Radius Bend

YANHAO is a professional elbow manufacturer, supplier and exporter. We can produce long radius 180-degree Short Radius Bend (ASME B16.9 standard). These elbows are made of carbon steel, stainless steel or alloy steel materials, with small flow pressure loss, strong system compatibility, and will not easily cause corrosion, pitting, rust, or wear in the pipeline system. At the rated operating temperature and pressure, the service life reaches more than 50 years. It can be connected to other pipelines through welding neck flanges, threaded flanges and socket welding flanges.

According to the project requirements, we can also produce other non-normal angle elbows/bends including 60°, and also customize elbows with different wall thicknesses as required.

- Types: Bend

- Degree: 90°

- Sizes: 1″ to 24″ NPS

- Material: Carbon Steel & Alloy Steel & Stainless Steel

- Production: Hot Pushing, Stamping, Socket Welding

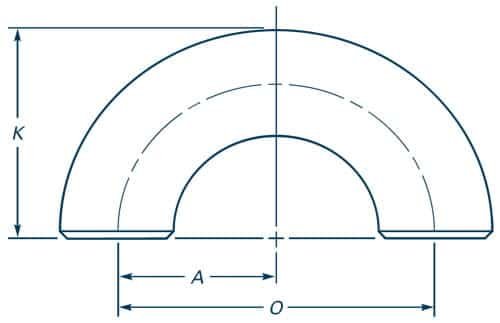

180-degree Short Radius Bend dimensions

NOTE : Dimension A is equal to 1/2 of dimension D.

| Nominal Pipe Size | Outside Diameter at Bevel mm (in.) | Center to Center 0,mm(in.) | Back to Face K,mm(in.) |

|---|---|---|---|

| 1 | 33.4 (1.32) | 51 (2.00) | 41 (1.62) |

| 1% | 42.2 (1.66) | 64 (2.50) | 52 (2.06) |

| 1% | 48.3 (1.90) | 76 (3.00) | 62 (2.44) |

| 2 | 60.3 (2.38) | 102 (4.00) | 81 (3.19) |

| 2% | 73.0 (2.88) | 127 (5.00) | 100 (3.94) |

| 3 | 88.9 (3.50) | 152 (6.00) | 121 (4.75) |

| 3% | 101.6 (4.00) | 178 (7.00) | 140 (5.50) |

| 4 | 114.3 (4.50) | 203 (8.00) | 159 (6.25) |

| 5 | 141.3 (5.56) | 254 (10.00) | 197 (7.75) |

| 6 | 168.3 (6.62) | 305 (12.00) | 237 (9.31) |

| 8 | 219.1 (8.62) | 406 (16.00) | 313 (12.31) |

| 10 | 273.0 (10.75) | 508 (20.00) | 391 (15.38) |

| 12 | 323.8 (12.75) | 610 (24.00) | 467 (18.38) |

| 14 | 355.6 (14.00) | 711 (28.00) | 533 (21.00) |

| 16 | 406.4 (16.00) | 813 (32.00) | 610 (24.00) |

| 18 | 457.0 (18.00) | 914 (36.00) | 686 (27.00) |

| 20 | 508.0 (20.00) | 1016 (40.00) | 762 (30.00) |

| 22 | 559.0 (22.00) | 1118 (44.00) | 838 (33.00) |

| 24 | 610.0 (24.00) | 1219 (48.00) | 914 (36.00) |

YANHAO typically uses the following elbow material grades:

These materials possess excellent abrasion resistance, corrosion resistance, and heat resistance, and can be widely used in the power, metallurgy, mining, and chemical industries for the transportation of sand, stones, coal powder, slag, aluminum liquid, and corrosive media. They are also suitable for high-temperature steam transportation pipelines, water-gas pipelines, and other transportation pipeline systems.

Long Radius Elbow

The curvature radius of the elbow can be divided into long radius elbow and short radius elbow. The radius of curvature of the long-radius elbow is equal to 1.5 times the outer diameter of the pipe, that is, R=1.5D; if it is greater than 1.5 times, it is an elbow.Long radius elbow is a commonly used elbow, usually used in pipelines with high pressure or high flow rate. If the resistance requirements of the transportation pipeline are strict, a larger radius elbow needs to be used.

According to different manufacturing methods, it can be divided into push elbow, extrusion elbow and welded miter elbow. Push elbows and squeeze elbows are commonly used on small and medium-sized pipes. Welded miter elbows are used on large-size pipelines. When the miter angle of the miter elbow is greater than 450, it is not suitable to be used on pipelines with highly toxic or flammable media, or withstand mechanical vibrations and alternating loads caused by temperature changes. on the pipeline