Flange Types: A Comprehensive Guide and Their Applications

Flanges are essential parts of piping systems. They offer a secure connection between pipes, valves, and equipment for easy inspection, cleaning, or modification. Understanding the different types of flanges in piping is crucial for selecting the right components for specific applications. Flanges are indispensable in industries dealing with oil and gas, chemical processing, and energy production, with various types targeted to meet unique requirements. Effective operation of these systems requires an understanding of the features and functionality of each type of flange.

What is a flange?

A flange is a flat, circular, or ring-like component that joins two parts of a piping system. It is normally bolted into place using precisely aligned bolt holes to ensure a secure connection. These bolt holes are essential for attaching flanges to pipes or equipment, providing a reliable seal with the help of a gasket High-pressure and high-temperature conditions need to be handled.

Thus, flanges are made to withstand them and be stable as well. In addition to their principal purpose of linking pipes and components, flanges are essential for system flexibility, enabling the replacement, expansion, or rerouting of pipelines without major interruptions. The bolt holes on flanges play a crucial role in this flexibility, allowing for easy disassembly and reassembly.

Different Types of Flanges and Their Applications

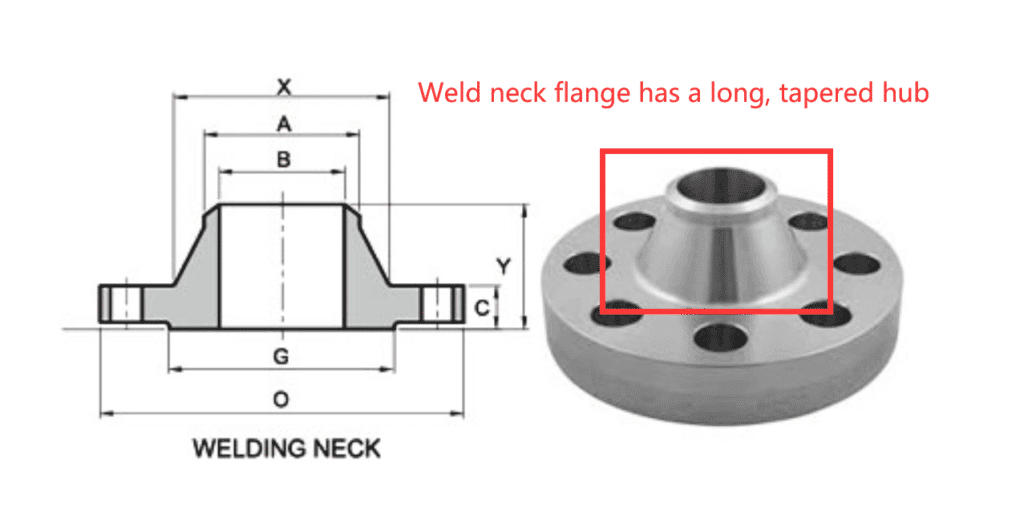

Weld Neck Flanges (WN)

WN flange, also known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, the rim, is fitted around the circumference.

China welding neck flange products >>

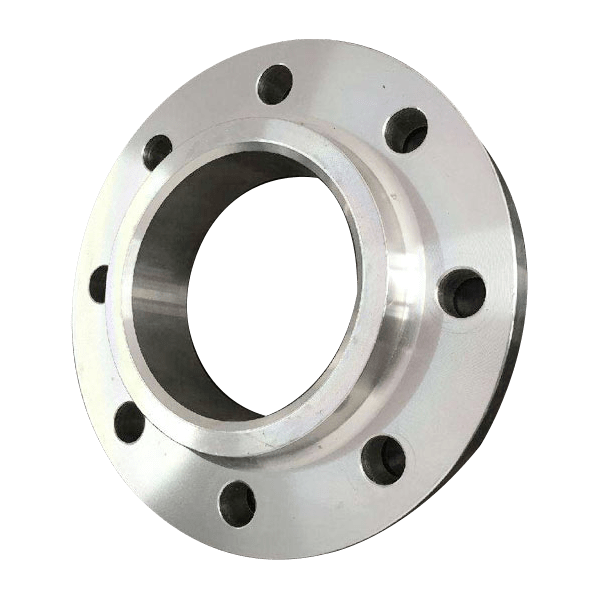

Slip-on Flanges (SO)

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

China slip-on flange products >>

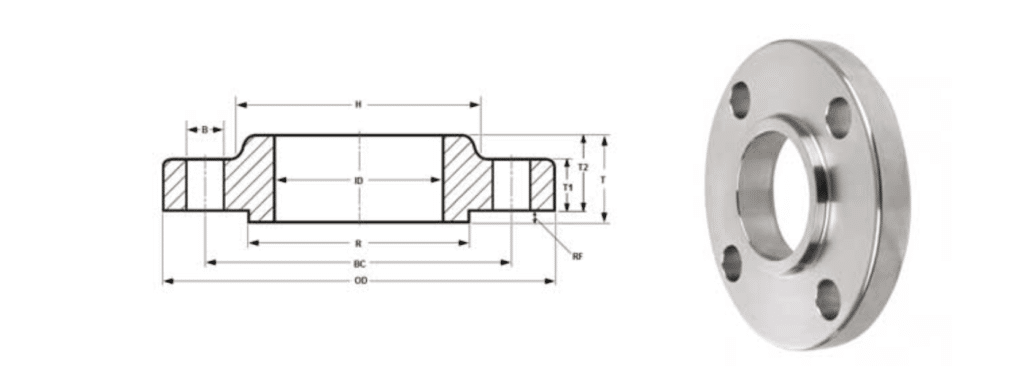

Socket Weld Flanges (SW)

Socket Weld Flanges (SW) are similar to Slip-on Flanges (SO). The difference is that there is an extra piece in the middle.

China socket weld flange products >>

Blind Flanges (BF)

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints.

China blind flange products >>

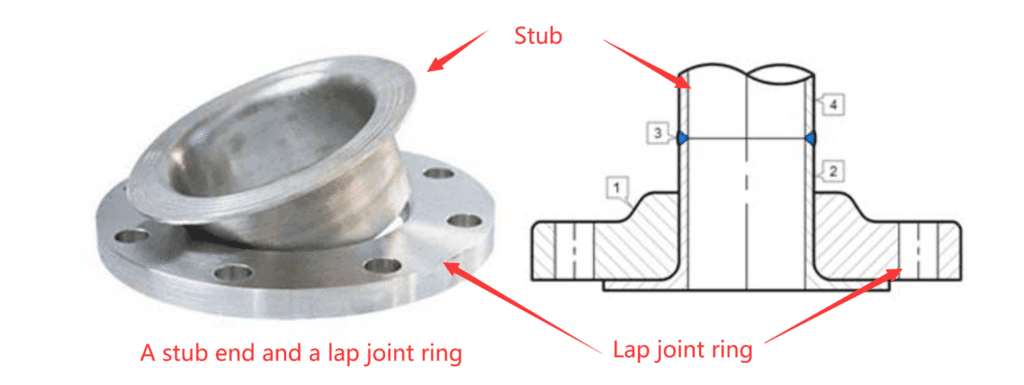

Lap joint flange (LJ)

Consisting of two components: a stub end and a lap joint ring flange. The respective stub end is slid into the flange’s bore, and the stub end is joined to the pipe through butt welding.

China lap joint flange products >>

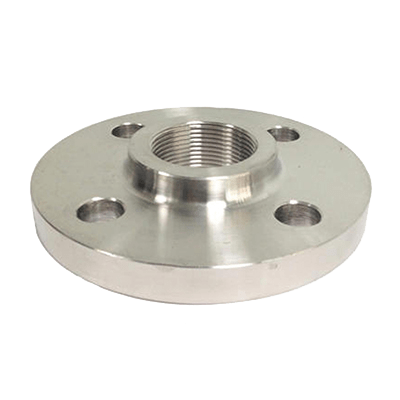

Threaded Flanges (TF)

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe. The installation does not involve welding

China threaded flange products >>

Weld Neck Flange

A weld neck flange has a long, tapered hub that provides an even distribution of stress in the pipe and flange connection.

These flanges are butt-welded to the pipe, thus making a reliable and permanent joint capable of standing in extreme conditions.

Weld Neck Flange Applications

- High-pressure systems at refineries of oil and gas.

- Steam pipelines in power plants.

- Lines for chemical processing are subjected to variations in temperature and pressure.

- Critical piping networks for minimum turbulence and maximum endurance.

Slip-On Flange

A slip-on flange is a type of flange that’s slipped over the end of a pipe or fitting and then welded in place.

This design that offers a smooth bore with less flow restriction makes it suitable for small-diameter, high-pressure piping.

Slip-On Flange Applications

- Industrial plant cooling water systems.

- For fire protection systems and sprinkler lines.

- Use for low-pressure process lines manufacturing and HVAC systems.

- Pipelines for which dismantling or realignment is not required frequently.

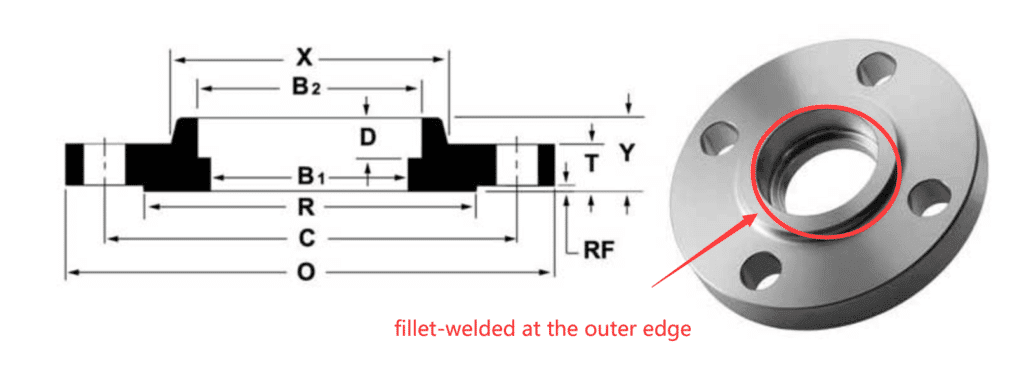

Socket Weld Flanges

A socket weld flange comes with a socket where the pipe is placed and then fillet-welded at the outer edge. Socket weld flanges (SW) are similar to slip-on flanges (SO). The difference is that there is an extra piece in the middle.

This recessed design makes them ideal for smaller-diameter pipelines where high structural integrity with minimum leakage is required.

Applications:

- Industrial machinery hydraulic and pneumatic systems.

- Where leakage prevention is critical for chemical and food processing industries.

- Aviation or marine high-pressure fuel lines.

- Systems for carrying non-corrosive or low-corrosive fluids.

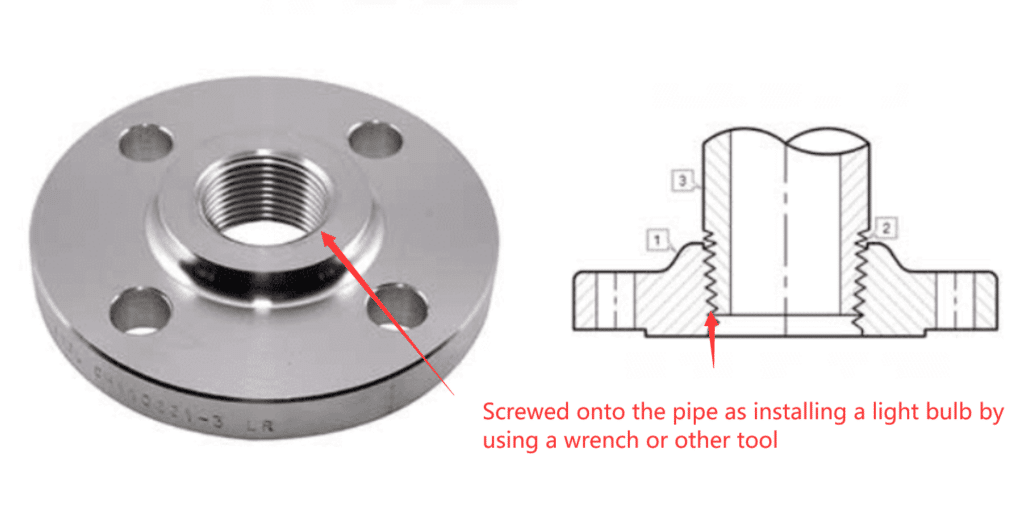

Threaded Flange

Threaded flanges are screwed onto the pipe without welding, relying on matching threads at the pipe and flange.

This makes them easy to put in and perfect for applications where welding is impractical.

Applications

- Low-pressure water supply lines within plumbing systems.

- Temporary piping systems for construction or testing.

- Industrial and commercial facilities, air and gas utility services.

- Hazardous environments that are considered dangerous for welding work.

Blind Flange

Blind flanges are solid discs that fit onto the end of a pipe or vessel, providing easy access for an inspection and modification; fluids or gases are prevented from flowing or leaking.

Applications:

- Closing off unused pipeline sections of oil and gas installations.

- In chemical plants, pressure vessels and storage tanks.

- Systems that would require maintenance periodically or that would need to be expanded in the future.

- Applications in high-pressure power generation and petrochemical industries.

Lap Joint Flange

The lap joint flanges are used with a stub end and are not welded directly to the pipe.

They are designed for easy assembly and disassembly, minimizing the material costs.

Applications:

- Food processing and pharmaceutical pipework require regular maintenance or cleaning.

- Corrosive or abrasive substances are handled by high-pressure systems.

- Easy realignment required maintenance-intensive pipelines.

- In applications requiring material flexibility, the flange material can be different from the pipe material.

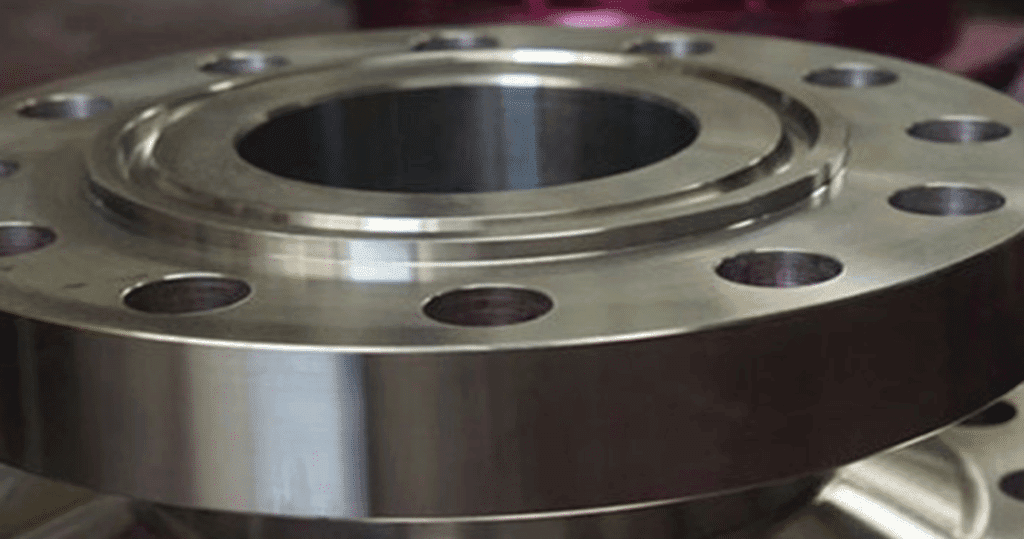

Ring-Type Joint (RTJ) Flanges

RTJ flanges are precision machined to have a groove where the metal ring gasket sits to ensure a leak-proof connection.

These are for critical applications that demand high-integrity seals.

Applications:

- High-pressure oil and gas pipelines.

- Petrochemical facilities, offshore drilling rigs.

- Systems involving hazardous or corrosive materials.

- Power generation plants and high-temperature environments.

Long Weld Neck Flanges

Long weld neck flanges (customized flange) are extended from the pipe with a long neck that transitions smoothly, making them suitable for high-stress applications.

Long Weld Neck Flanges are not particularly common, and usually YANHAO customers will find them for special customization.

Applications:

- In industrial plants, pressure vessels and heat exchangers.

- Boiler manufacturing and maintenance.

- Piping systems of nuclear power plants.

- For applications with connections in confined spaces or hard-to-reach areas.

Key Factors in Choosing the Right Flange

Operating Pressure and Temperature

Flanges should be capable of withstanding the pressure and temperature of the fluid or gas within the system. For example, weld neck or ring-type joint (RTJ) flanges are better in a high-pressure and high-temperature environment, such as in oil refineries or steam pipelines.

A slip-on or threaded flange would be suitable for low-pressure applications. The bolt holes in these flanges are designed to accommodate standard bolts, ensuring a secure and reliable connection. Identify whether the flange is rated for a pressure class with ANSI or ASME standards to prevent failure.

Pipe Size and Material Compatibility

The flange must be the same diameter and wall thickness as the pipe so that it makes a secure connection. Also, flange material should be usable with the pipe and with transported substances in order to avoid corrosion or degradation. For example:

- Because they are stainless steel, these flanges are ideal for corrosive environments.

- The general industrial applications of carbon steel flanges are found to be wide.

- Some specific chemical processes may use non-metallic flanges, like plastic or composite.

Environmental Conditions

Flange selection is largely a function of environmental factors like chemicals, moisture, or extreme temperatures that can affect them. For instance:

- Co-corrosion-resistant materials in coastal or offshore applications require duplex stainless steel.

- Systems in cryogenic environments may require some low temperatures.

- Used in harsh industrial settings, flanges are wear- and abrasion-resistant.

Installation and Maintenance Requirements

When selecting a flange, consideration should be given not only to ease of installation but also to future maintenance requirements. When systems are to be disassembled and assembled fairly frequently, flanges such as lap joints offer convenience. They do not have to be welded to the pipe. Thus, they are easily replaced and adjusted. For more permanently installed and high-pressure applications, a weld neck or socket weld would be preferred for their strength and secure connections.

Cost Considerations

Budget is an important factor when selecting the right frame. There are more economical options, like slip-on flanges for low-stress or non-critical systems, providing an effective solution. However, high-performance, high-pressure, and specialized applications will require higher-priced flanges, such as RTJ or long weld neck flanges, to allow for reliability and safety concerns. It is very important to achieve a balance between cost and what the operation of the system requires for both economic efficiency and long-term durability.

Pressure Ratings and Standards

| Pressure Rating | Class (ANSI/ASME) | Typical Applications | Material Compatibility |

|---|---|---|---|

| 150 | ANSI Class 150 | Low-pressure systems | Carbon steel, Stainless steel |

| 300 | ANSI Class 300 | Medium-pressure systems | Carbon steel, Stainless steel |

| 600 | ANSI Class 600 | High-pressure systems | Carbon steel, Alloy steel, Stainless steel |

| 900 | ANSI Class 900 | High-pressure, high-temperature systems | Alloy steel, Stainless steel |

| 900 | ANSI Class 900 | High-pressure, high-temperature systems | Alloy steel, Stainless steel |

| 1500 | ANSI Class 1500 | Extreme pressure systems | Stainless steel, Nickel alloys |

| 2500 | ANSI Class 2500 | Very high-pressure systems | Stainless steel, Nickel alloys |

| DIN PN6 to PN64 | DIN 2501 | European standard for pressure systems | Carbon steel, Stainless steel, Alloy steel |

YANHAO: Your Trusted Flange Manufacturer

YANHAO is one of the foremost flange manufacturers with high-quality flanges, which provide different types to meet the various demands of industries around the world.

YANHAO guarantees precision engineering and longevity with the use of durable materials for every flange designed to deliver long-lasting performance, reliability, and safety in different applications. YANHAO offers flanges for high-pressure systems and corrosive environments and regular installation according to international standards.

At YANHAO, we offer quality flange solutions where every customer is prioritized and satisfied. For more information about our comprehensive financing, reach out to us.

Bottom Line

The selection of the proper flange ensures the efficiency, safety, and long life of your piping system.

With proper knowledge of the different types of flanges and their applications and taking into account operating pressure, temperature, pipe material compatibility, and environmental conditions, you can maximize your performance.

Also, remember to balance cost with the particular requirements of your project when making a well-informed decision. YANHAO’s range of high-quality flanges and professional advice will help you choose the right flange for your needs.

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.