Slip-On Flanges

Made in China Slip-On Flanges. We can produce flanges to ASME standards, as well as flanges that meet other standards. You can also provide drawings and let us produce custom flange products.

China Slip-On Flanges

We provide flange products of various standards, such as ASME/ANSI B16.47, EN standards, etc. We also provide customized Slip-On Flanges products.

As a company with 25 years of flange production experience, we support all types of flanges, and we can give you the best product quality, the most reasonable price.

lewis Liu

Sales Manager

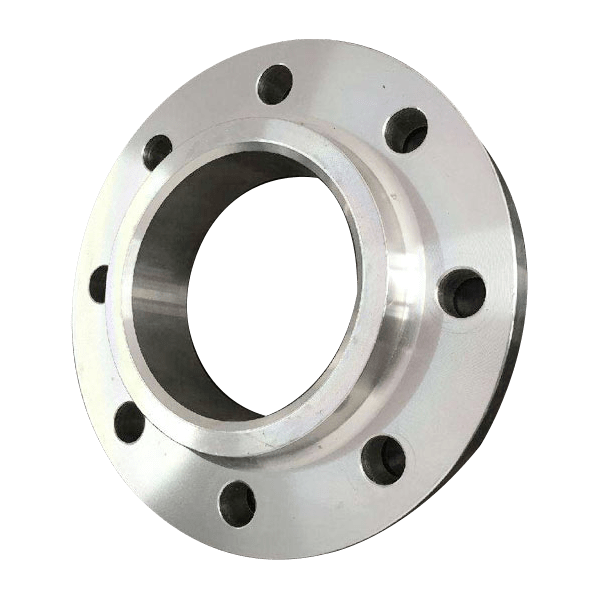

What is Slip-On Flanges

Slip-on flange is a pipe connection fitting and a type of random flange. It is connected to the container or pipe through a fillet weld and is designed to be either integral or loose flange. The flange rings of slip-on flanges are of two types: with neck and without neck.

Compared with necked butt-weld flanges, slip-on flanges have a simpler structure and use less material, but their rigidity and sealing are slightly inferior to necked butt-weld flanges.

Slip-on flanges are widely used in the connection of medium- and low-pressure containers and pipelines.

Slip-On Flanges Product Image Gallery

Here are various Slip-On Flanges produced by YANHAO. You can click on the pictures to enlarge them. As a company with 25 years of flange production experience, YANHAO supports all types of flange production.

Standardized Slip-On Flanges

- Slip-On Flanges are commonly standardized as ASME B16.5, with sizes ranging from 1/2 inch to 60 inches.

- Sealing surface types include raised face (RF), flat face (FF), dimpled face (MFM), tongue and groove (TG), ring joint (RJ), and so on.

- Applicable pressure classes include Class 150, 300, 400, 600, 900, 1500.

Customized Slip-On Flanges

The following options are for you to customize. If you don’t have a design drawing, you can also consult our engineers and let us help you draw it.

size

Specified pipeline size, including flange ID and OD, thickness, bolt hole diameter, bolt hole distance, etc.

Material

Using specified material suitable for pipeline engineering according to your requirements.

Shape

can be customized with irregular flanges such as square flanges, and conical flanges, etc.

Connection

Threaded connection, welding connection, socket welding connection, etc., which can be selected.

Special Treatment

Special treatments such as surface coatings, anti-corrosion can be made according to your needs.

The customization process for flanges is generally as follows:

requirements

Confirmation

Communicate in detail to determine the requirements for flange size, material, pressure, connection method, etc.

Design drawings

Our professional engineers will design flange drawings for you. The drawings will specify the size, shape, thickness, etc. of the flange in detail.

Choose materials

Select suitable flange materials according to the requirements of the engineering project.

Customer confirmation

Send detailed information such as the designed drawings and materials to the customer for confirmation.

Processing sample

To ensure accuracy, first produce a sample according to the drawings and selected materials and send it to the customer for trial confirmation.

Production of bulk goods

After confirming the accuracy of the samples, proceed with mass production.

More reading:

About YANHAO

YANHAO is a flange manufacturer located in Hebei Province, China. It is one of the few professional flange suppliers in China.

We have many years of experience in flange production and have multiple flange production lines. We have sufficient stock of raw materials, rich inventory, fast delivery, and can ship within three days. At the same time, the price is affordable. You are welcome to consult and purchase!

In addition, we can provide a variety of bespoke flanges and pipe fittings. Customers can give drawings or samples, and our company will produce them to fit your specific requirements.

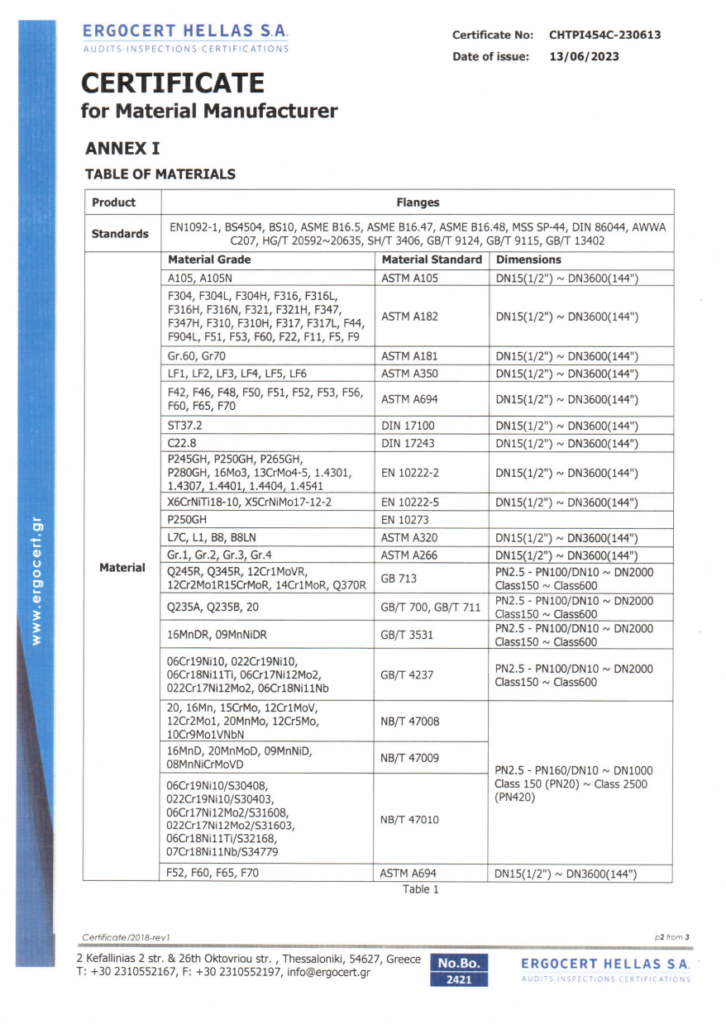

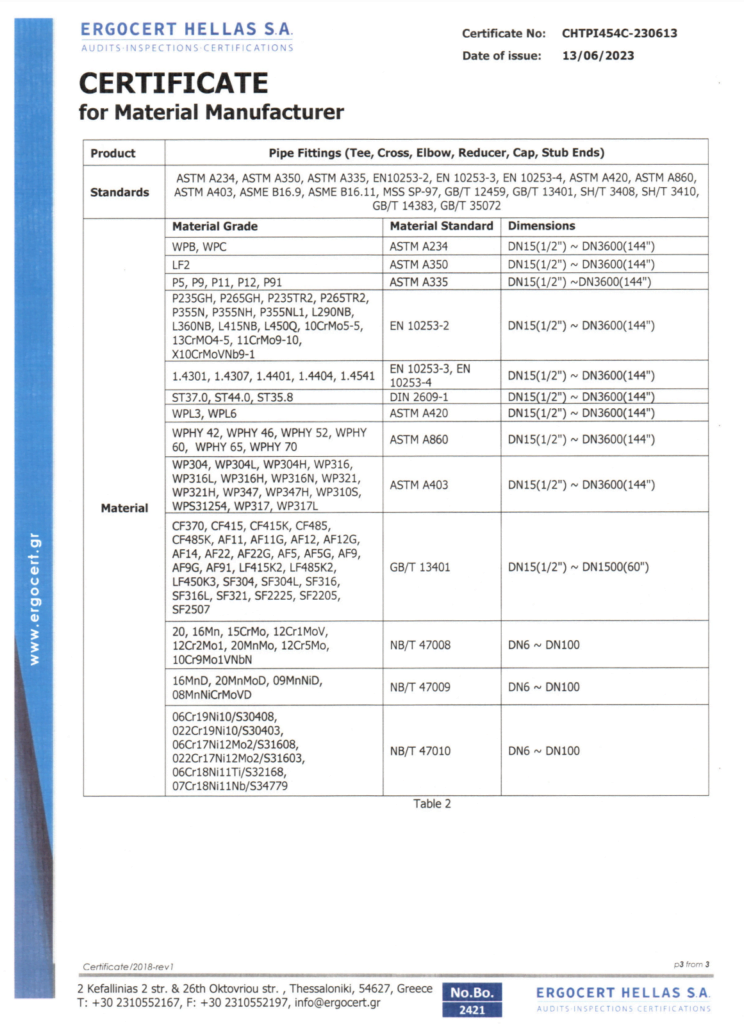

Check Our Certificates

specifications & characteristics of Slip-On Flanges

This table provides a comprehensive overview of Slip-On Flanges, covering key specifications, characteristics, and additional considerations. Specific details and requirements may vary based on the chosen flange size, pressure rating, and material.

| Specification/Feature | Description |

|---|---|

| Standard | ASME/ANSI B16.5 Slip-On Flange. |

| Type | Slip-On Flange – A type of flange with a slightly larger bore than the pipe, which slips over the pipe end and is then welded to provide a secure connection. |

| Pressure Ratings | Available in different pressure classes, such as 150, 300, 600, 900, 1500, 2500, etc., to accommodate varying pressure requirements. |

| Size Range | Typically available in sizes ranging from 1/2 inches to 48 inches or larger, suitable for various pipe and equipment sizes. |

| Materials | ASME/ANSI B16.5 Slip-On Flanges can be manufactured from materials like carbon steel, stainless steel, alloy steel, and more, chosen based on application requirements. |

| Facing Types | Common facing types include Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ), and Male and Female (M&F) facings, impacting sealing methods. |

| Bolt Hole Quantity and Diameter | The number and diameter of bolt holes vary with flange size and pressure rating, facilitating flange connection. |

| Connection Method | ASME/ANSI B16.5 Slip-On Flanges are slipped over the pipe end and then welded to the pipe, providing a secure and leak-resistant connection. |

| Application Areas | Slip-On Flanges are widely used in industries such as oil and gas, petrochemical, water treatment, and more for connecting pipes to flat-end equipment or vessels. |

| Standards and Codes | ASME/ANSI B16.5 Slip-On Flanges adhere to standards set by the American National Standards Institute (ANSI) and nominal pipe size (NPS) standards, such as ANSI B16.5. |

| Seal Types | Slip-On Flanges commonly use gaskets or O-rings for sealing, with the choice of seal type depending on the application and pressure rating. |

| Accessories and Attachments | Some applications may require additional components such as flange gaskets, bolts, nuts, flange covers, or flange cover gaskets. |

| Inspection and Testing | ASME/ANSI B16.5 Slip-On Flanges typically undergo a series of inspections and tests to ensure they meet quality and performance requirements, in compliance with standards. |

| Marking and Certification | Slip-On Flanges should be marked with the manufacturer’s identification, size, class, material, and other relevant information. Some flanges may require specific certifications such as PED or ASME. |

| Installation and Maintenance | Proper installation and regular maintenance of Slip-On Flanges, including weld integrity, bolt torque, flange face cleaning, and lubrication, are crucial for system integrity and performance. |

| Application Standards | In specific industries and applications, there may be industry-specific Slip-On Flange application standards that need to be adhered to for safety and performance. |