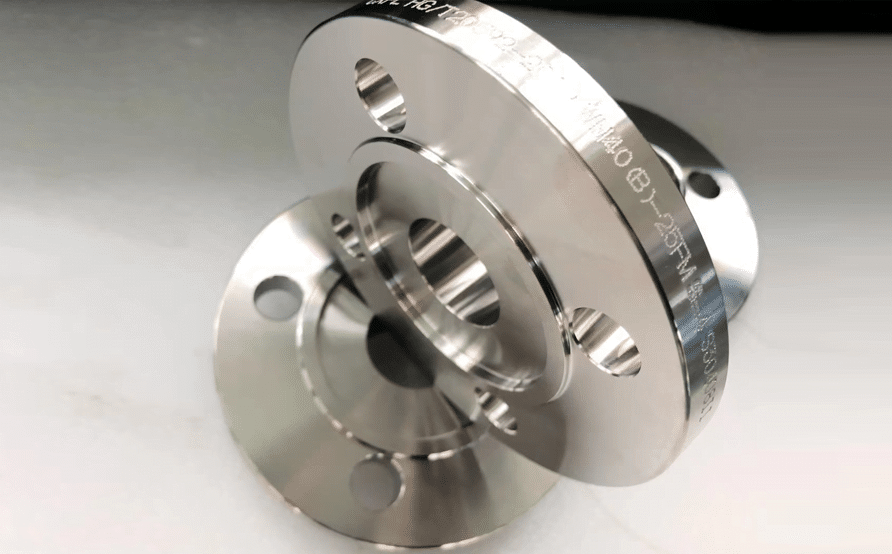

ASME flange

We offer ASME flanges in a variety of sizes and specifications.

The dimensions of ASME flange standards range from 1/2 “-60” and the pressure is Class150-Class2500. They are commonly used in pressure vessels, boilers, pipelines, and fittings, especially in projects involving high temperature and high pressure.

ASME Flange

ASME flange is a standard for flanges, developed by an international professional engineering organization, the American Society of Mechanical Engineers, abbreviated as ASMEI flange standard.

The dimensions of ASME flange standards range from 1/2 “-60” and the pressure is Class150-Class2500. They are commonly used in pressure vessels, boilers, pipelines, and fittings, especially in projects involving high temperature and high pressure.

The history and origin of ASME flanges

The American Society of Mechanical Engineers (ASME) is a professional organization of engineers established in 1880. The ASME B16 Committee was established in 1921 to develop standards related to pipeline flanges, fittings, and valve flanges. The ASME B16 Committee first issued the ASME B16.5 flange standard in 1973, which specifies the dimensions, pressure ratings, materials, and manufacturing requirements for pipeline flanges, flange fittings, and valve flanges. With the development of industry, the diameter of pipelines continues to increase. In 1982, the ASME B16 Committee issued the ASME B16.47 standard for large-diameter flanges. ASME B16.47 and ASME B16.5 constitute our main reference standards for American standard flanges.

ASME flange performance parameter table

| Standard: | ASME B16.5 (flanges between 1/2 inch and 24 inches in size) ASME B16.47 (flanges between 26 inches and 60 inches) |

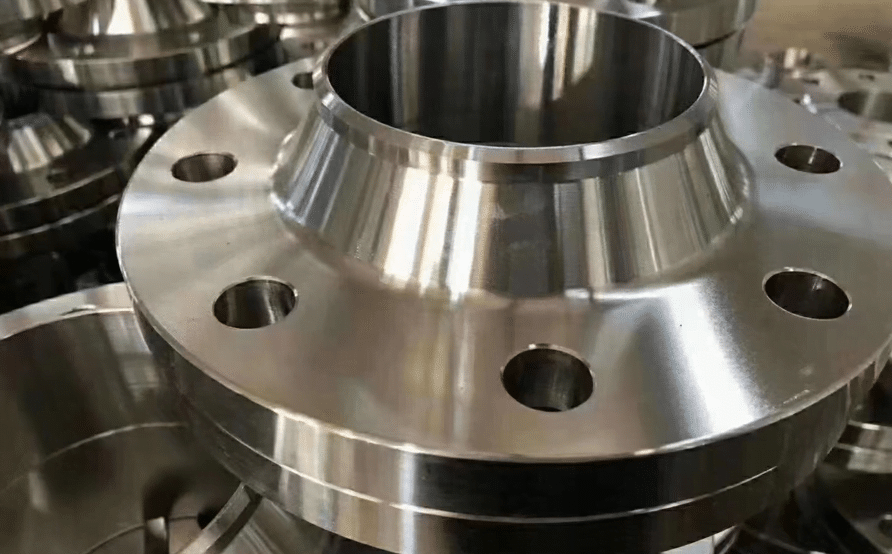

| Types: | Weld Neck Flange, Blind Flange, Slip-On Flange, Socket Weld Flange and Threaded Flange. |

| Size: | 1/2″ – 60″ |

| Pressure Rating: | Class150, Class300, Class600, Class900, Class1500, Class2500. |

| Material: | Common ANSI flanges are made of carbon steel (ASTM A105, ASTM A350 LF2), stainless steel (ASTM A182 F304, ASTM A182 F316), alloy steel (ASTM A182 F11, ASTM A182 F22, ASTM A182 F91) and other materials. |

| Sealing Face: | Flat Face(FF), Raised Face(RF), Male and Female Face(MF), Tongue and Groove Face(TG), Ring Joint Face(RJ) |

| Connection: | Bolt connection, Butt welding connection, Socket welding connection, Threaded connection. |

| Fabrication Process: | Forged Flanges: (Design->Raw Material Selection->Preheating->Forging->Processing->Welding->Heat Treatment->Surface Treatment->Testing and Inspection->Packaging and Delivery) Casting Flanges: (Design->Mold Making->Raw Material Selection->Casting->Cleaning and Dressing->Machining->Testing and Inspection->Surface Treatment->Packaging and Delivery) |

| Application areas: | In various equipment, pumps, valves, pipelines, and other engineering systems in the petroleum, natural gas, chemical, electric power, construction, ocean engineering, and other industries. |

Why ASME standard flanges and why and ANSI standard flanges performance parameters are the same? What is the difference between the two?

ANSI (American National Standards Institute) is ASME (American Society of Mechanical Engineers), an accredited organization, ANSI is mainly responsible for the management of engineering and technology-related standards, which happens to include flange standards. So they are from a certain sense is the same standard, in fact, ASME standard flange and ANSI standard flange parameters are the same, there is no difference, so this site will also be ASME/ANSI flange a piece of collation show.

So the material, selection, installation and routine maintenance of ASME flanges are undoubtedly the same as ANSI flanges, which will not be told here, please go to the ANSI flange page.