ASME B16.47 Flanges (Large Diameter Steel Flanges)

For NPS 26 – NPS 60 Pipes. Welding neck and blind flanges.

The ASME B16.47 Flange Standards are appropriate for the NPS 26 to NPS 60 pipe range. Covers in rating classes 75, 150, 300, 400, 600, and 900.

With 20 years of production experience, YANHAO offers a wide variety of ASME/ANSI flanges at competitive factory prices.

YANHAO offers:

NPS: Nominal Pipe Size, a North American standard size system for pipes meant to endure extremes of pressure and temperature. For example, when you say NPS 26, which means 26” pipe, the 26” is the nominal size of that pipe.

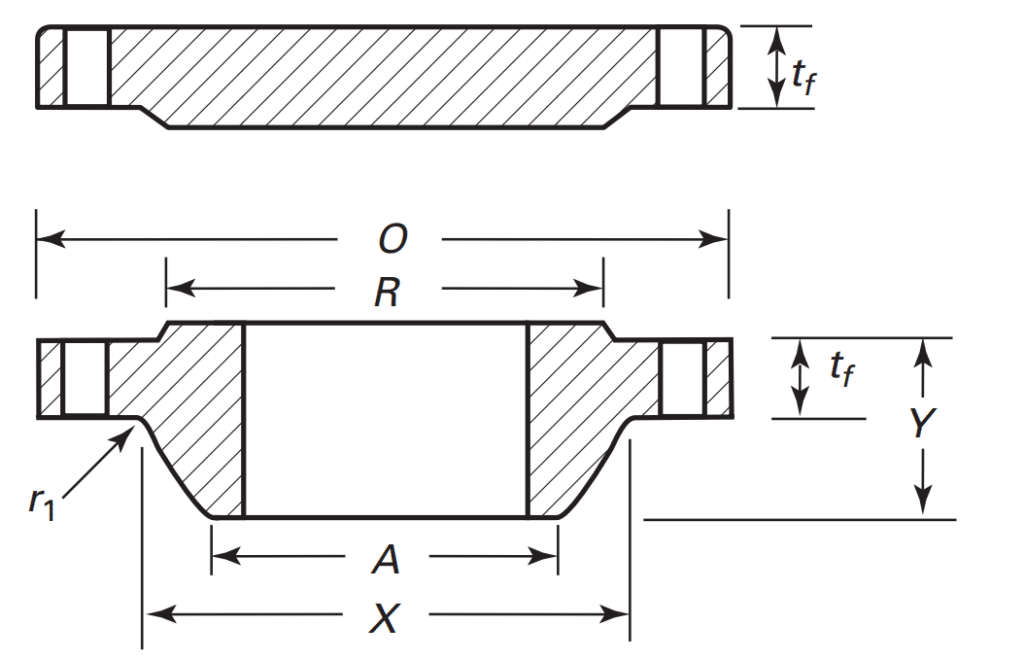

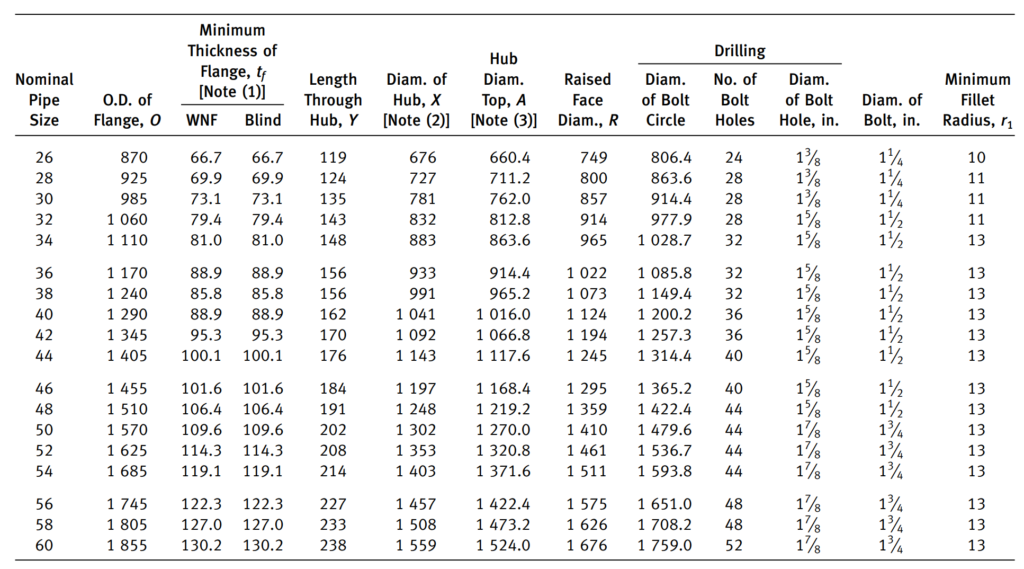

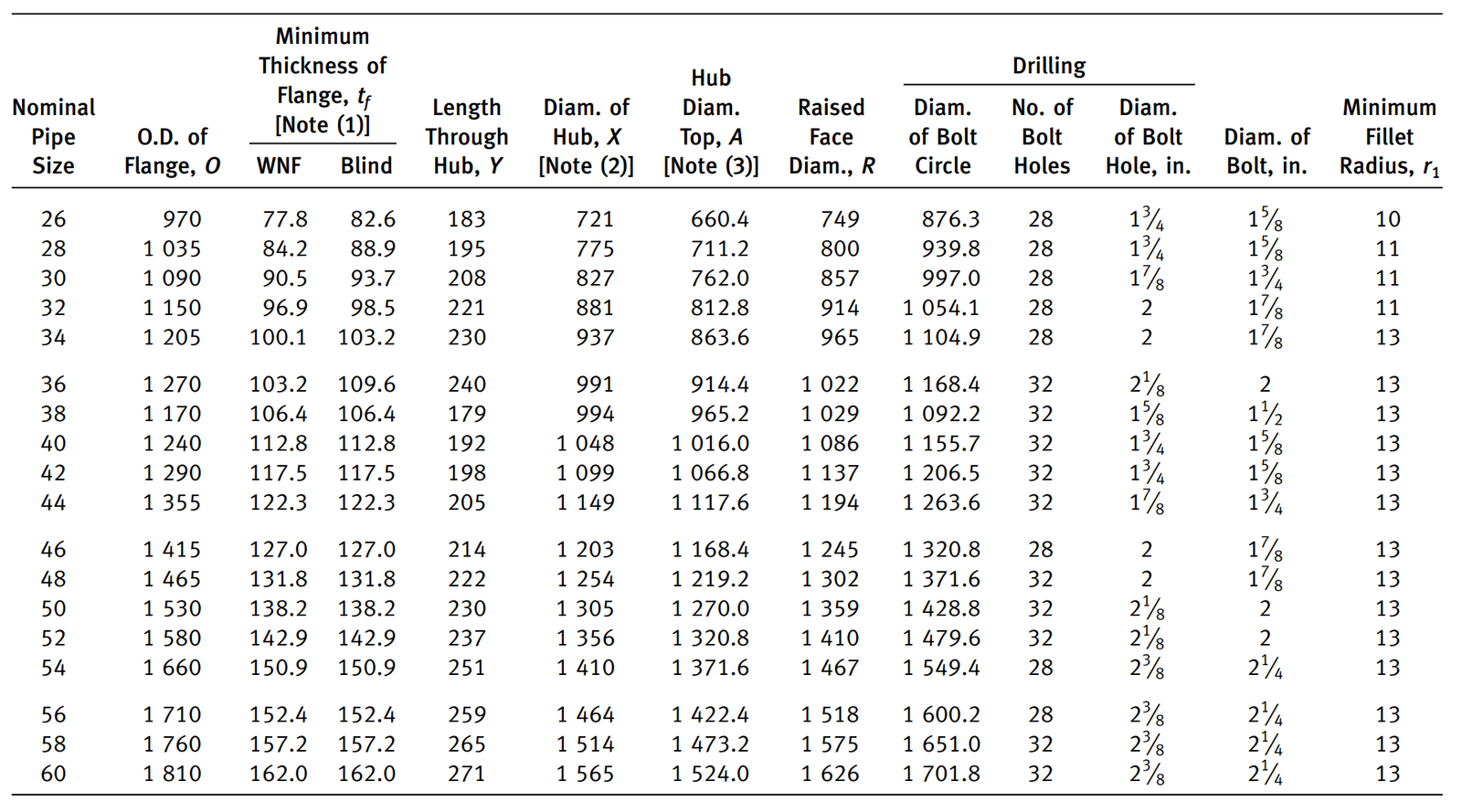

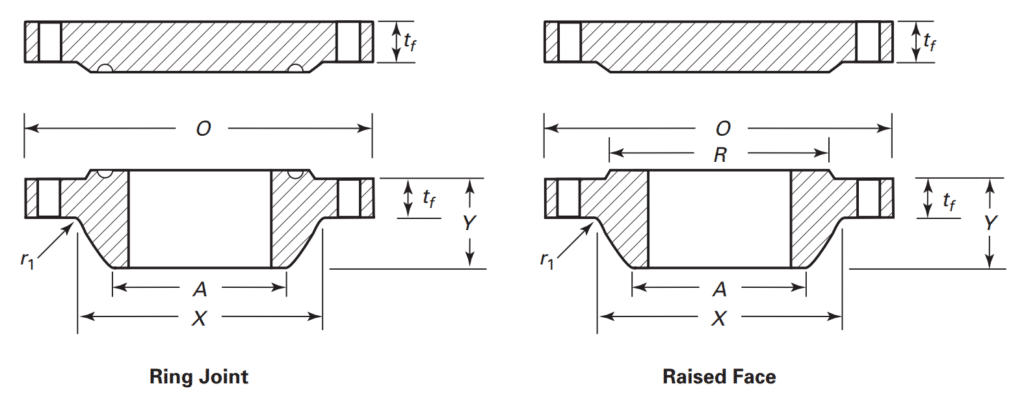

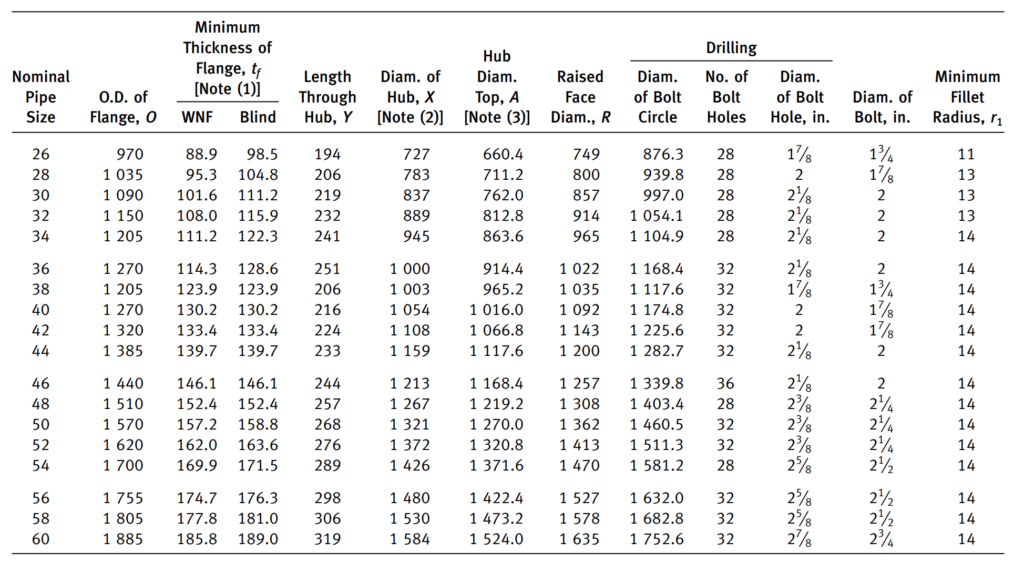

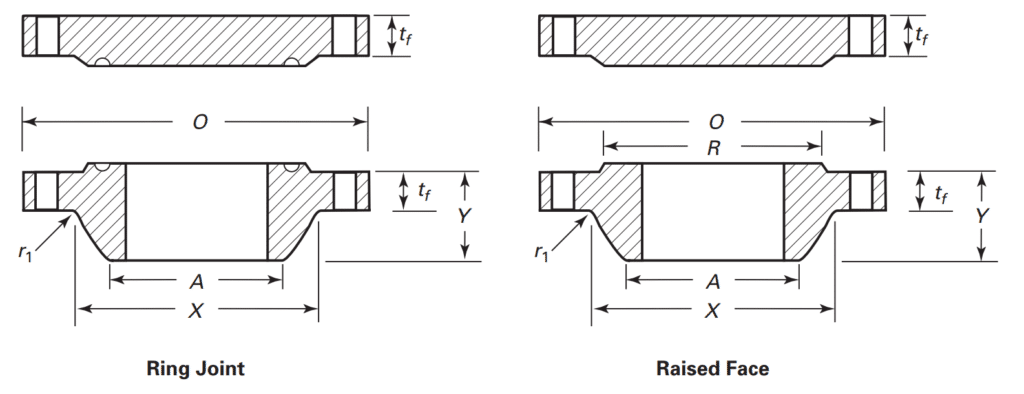

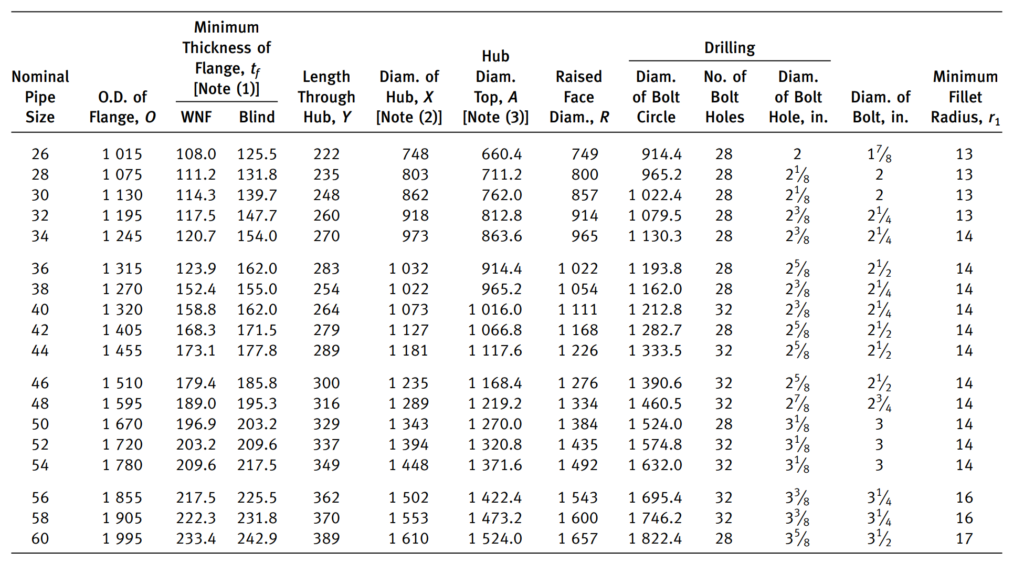

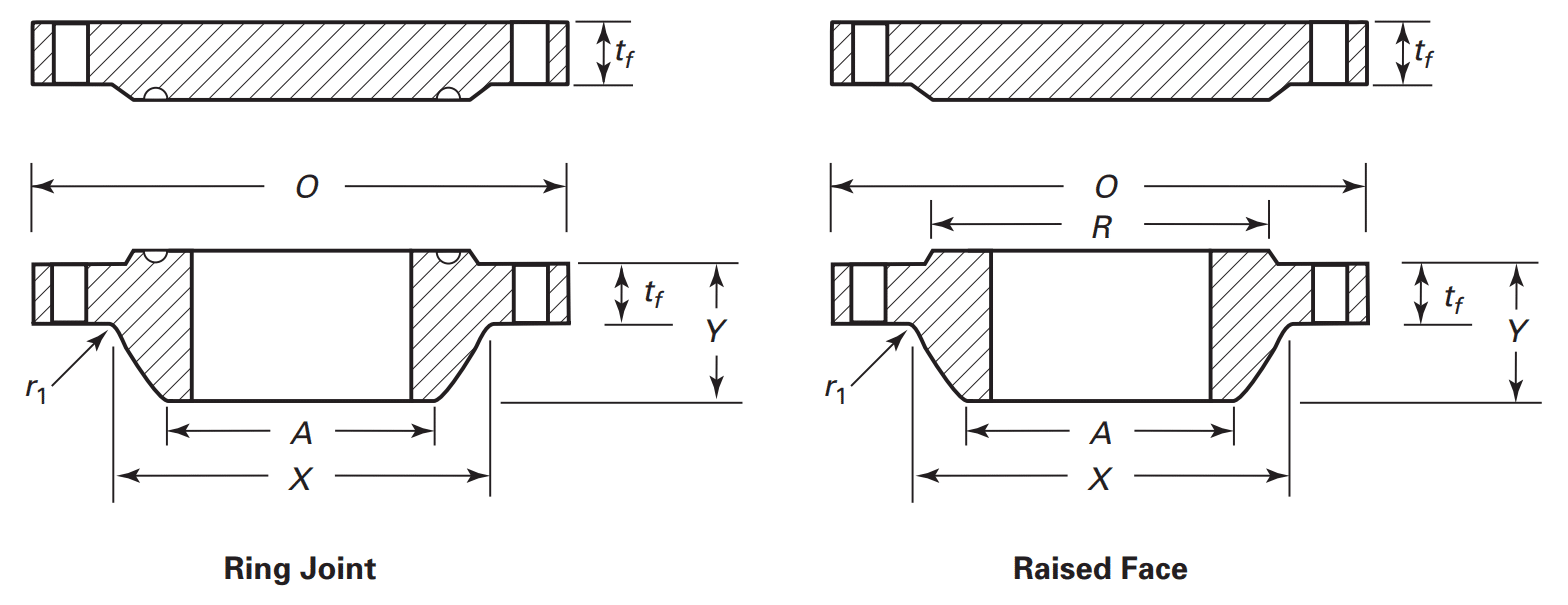

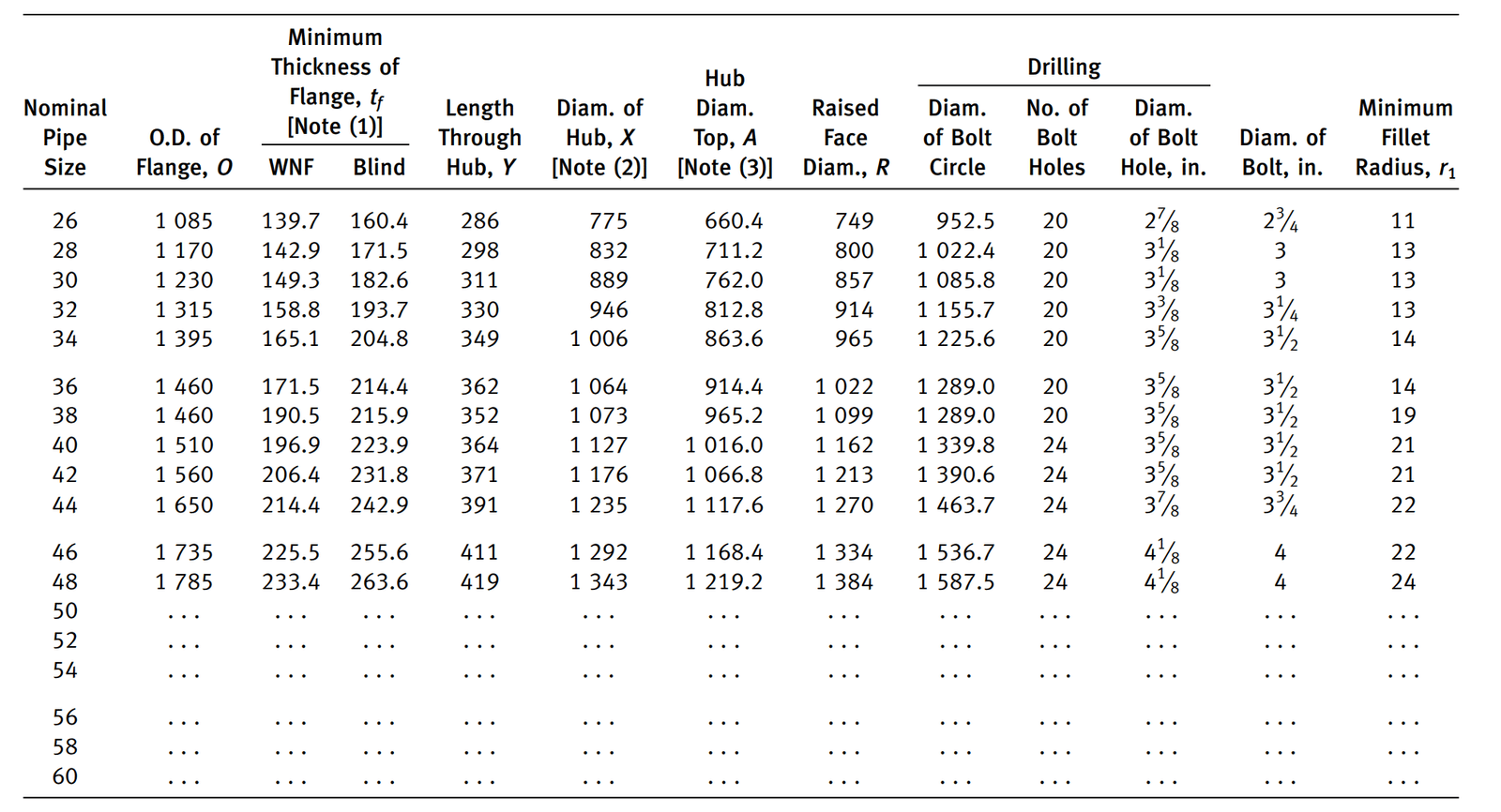

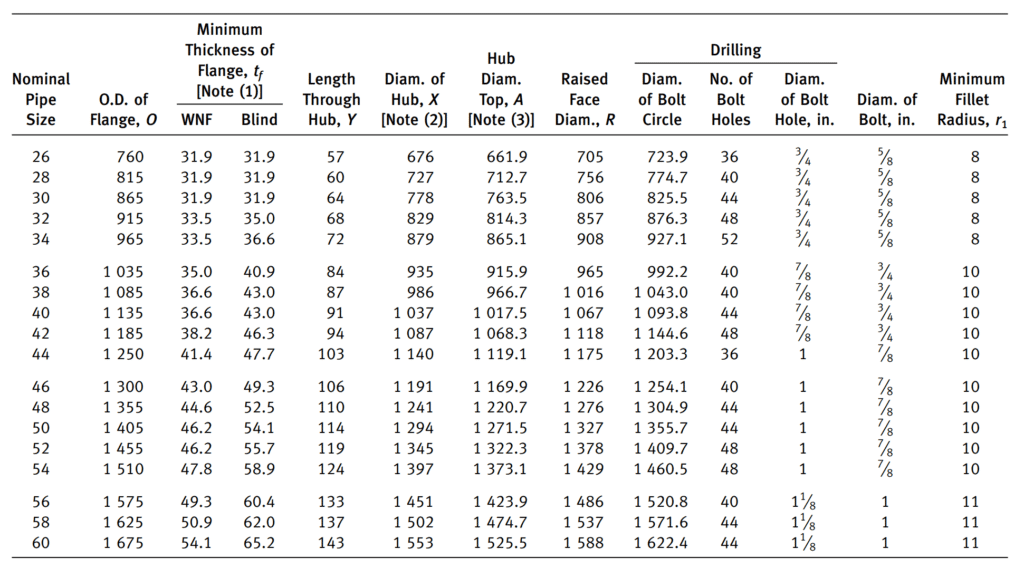

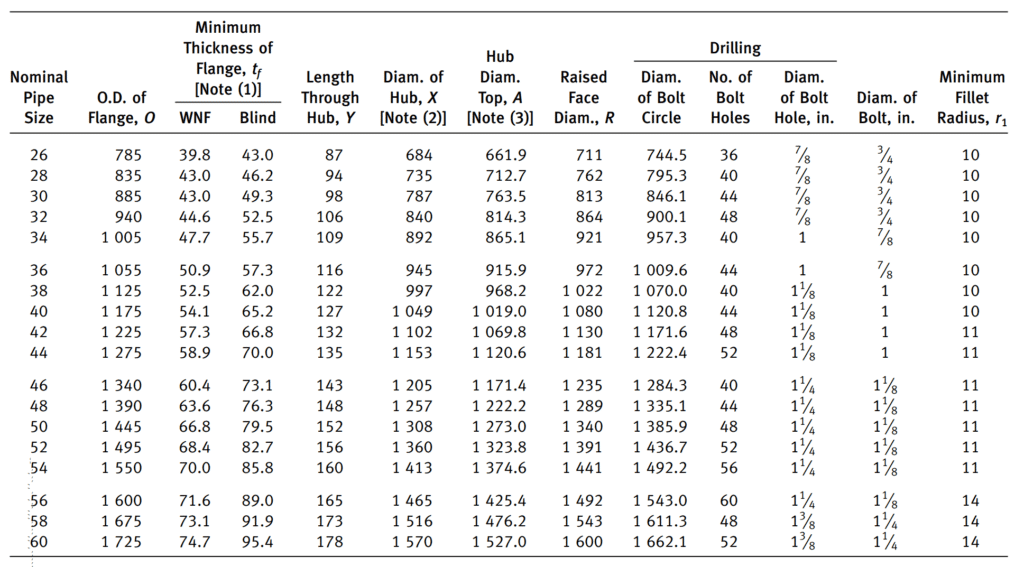

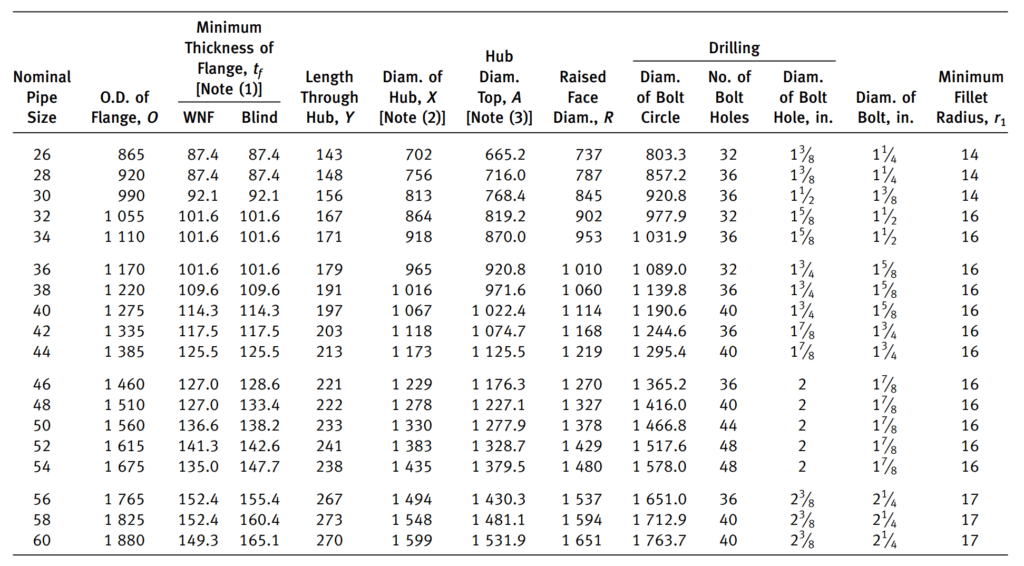

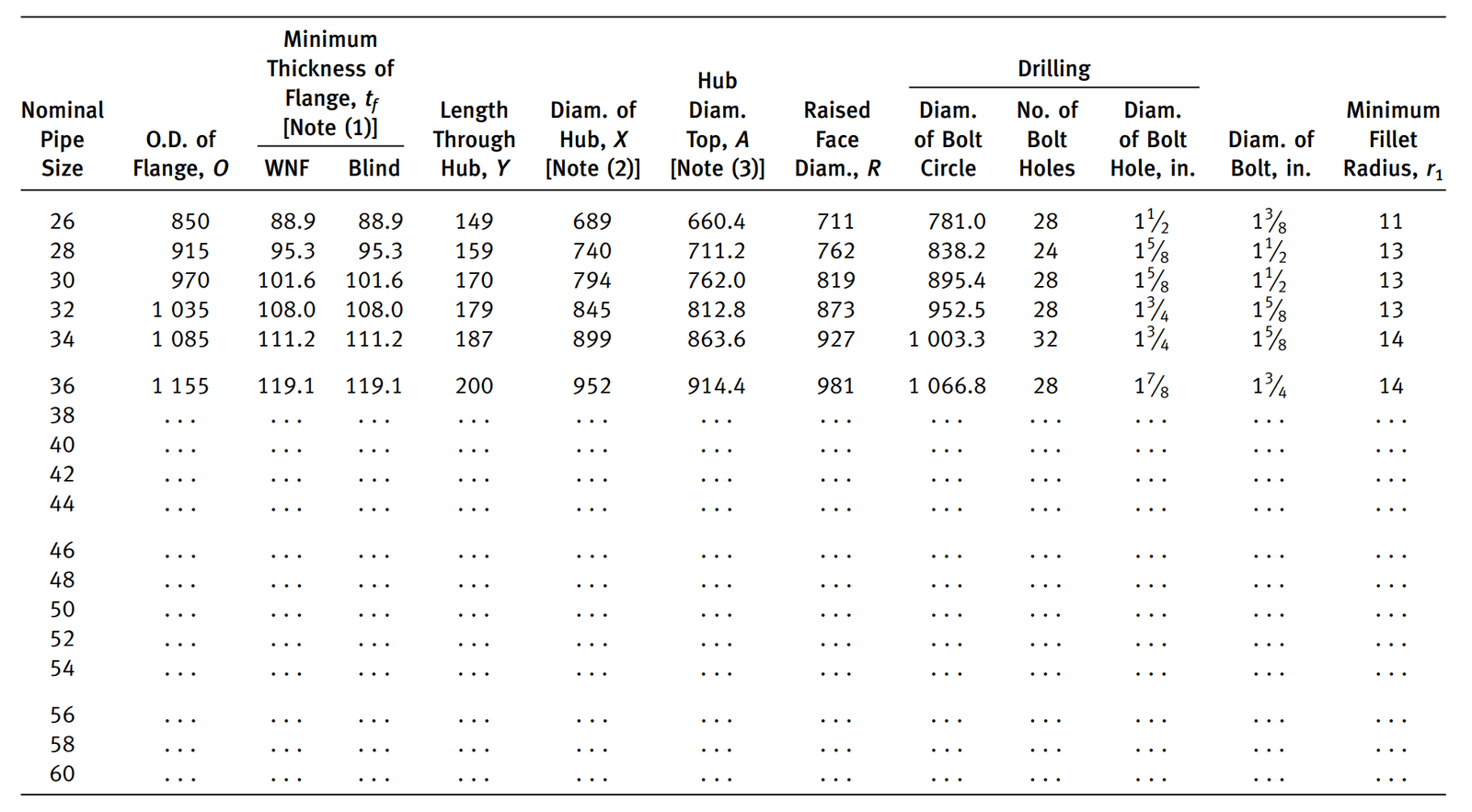

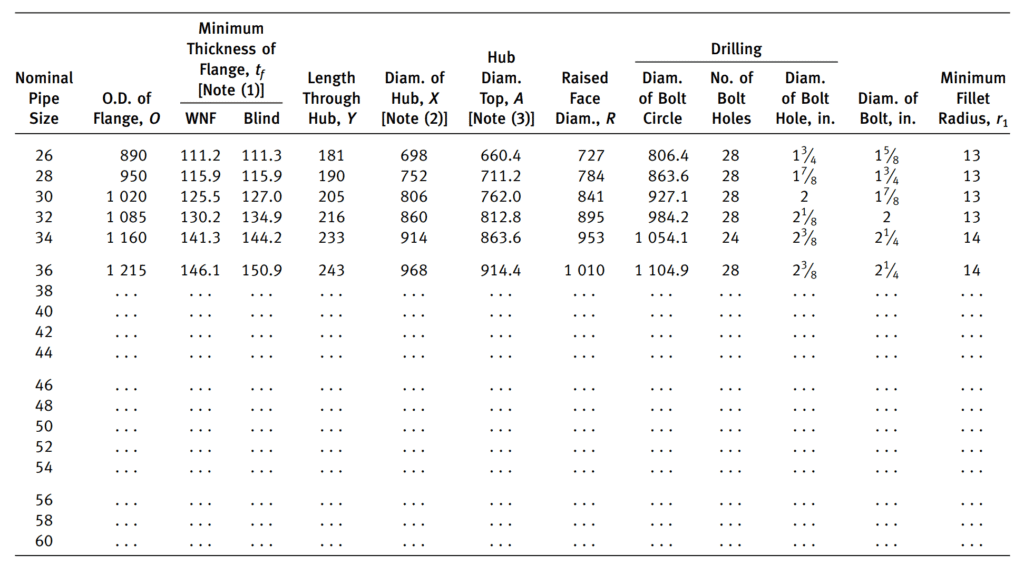

ASME B16.47 Flange Dimensions

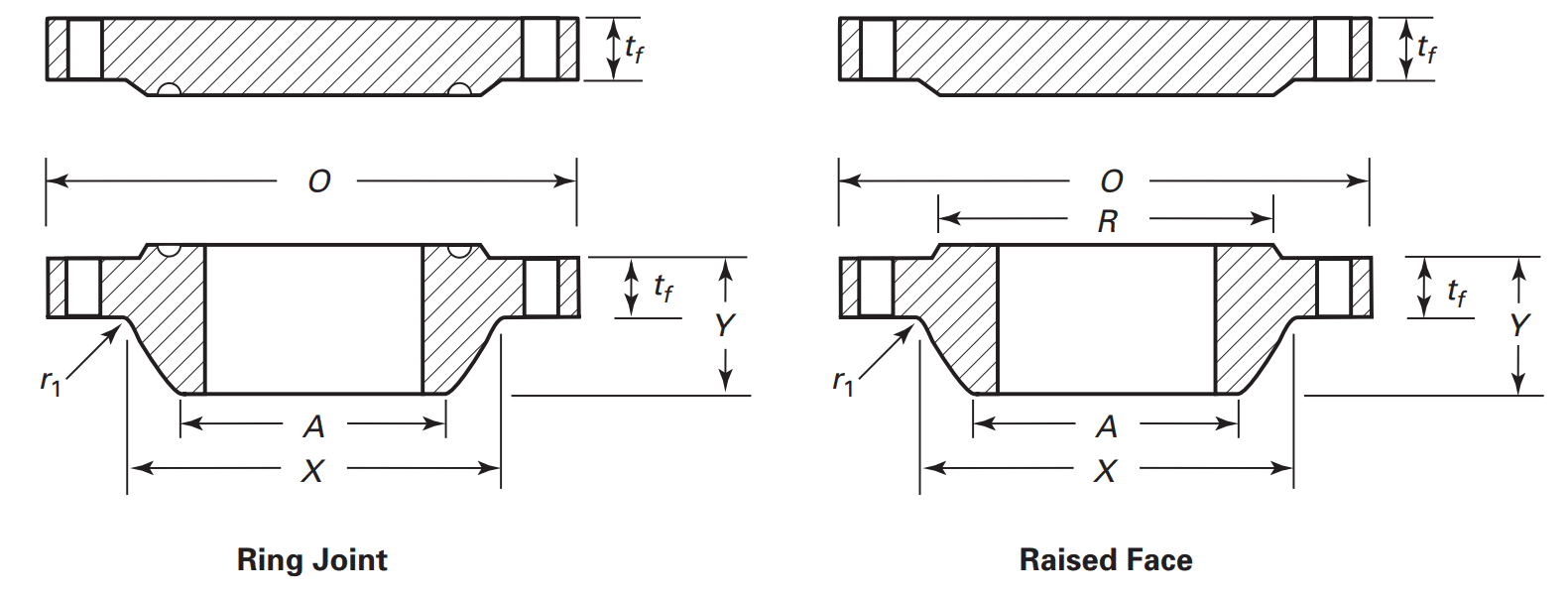

The ASME B16.47 Series A and Series B flanges have the following exact dimensions. Click on the image to magnify it. If you want to save the image locally, right-click it and choose [save as].

Recommend reading: ASME B16.47: Differences Between Series A & Series B Flange

Series A: Class 150, 300, 400, 600, 900, General-use Flange Dimensions

Series B: Class 75, 150, 300, 400, 600, 900, Compact Flange Dimensions

Notice:

About ASME B16.47 Flange Standard

The ASME B16.47 Flange Standard provides two series of flange dimensions.

- Series A is for general-use flanges.

- Series B is for compact flanges that, in most cases, have smaller bolt circle diameters than Series A flanges.

These two series of flanges are, in general, not interchangeable. The user should recognize that some flanged valves, equipment bolted between flanges, and flanged equipment may be compatible with only one series of these flanges

Classes 75, 150, and 300 flanges are regularly furnished with a 2 mm (0.06 in.) raised face. Classes 400, 600, and 900 flanges are regularly furnished with a 7 mm (0.25 in.) raised face.

The thickness of the raised face in all cases is in addition to the minimum flange thickness. It is recommended that the Class 75 flanges be used only with a 2 mm (0.06 in.) raised face or flat face.

Recommend reading: ASME B16.47: Differences Between Series A & Series B Flange

About YANHAO

YANHAO is a flange manufacturer located in Hebei Province, China. It is one of the few professional flange suppliers in China.

We have many years of experience in flange production and have multiple flange production lines. We have sufficient stock of raw materials, rich inventory, fast delivery, and can ship within three days. At the same time, the price is affordable. You are welcome to consult and purchase!

In addition, we can provide a variety of bespoke flanges and pipe fittings. Customers can give drawings or samples, and our company will produce them to fit your specific requirements.