Pipe Cap

Our company provides All Kinds of Pipe Cap

We provide Pipe Cap products of various standards, such as American standards, European standards, German standards, and Japanese standards. The list of common standards is as follows:

lewis Liu

Sales Manager

Cap could be ranged from connection types, shape types, material types.

Classified by Connection Types

As per the connection mode, Pipe Cap could be classified by Butt Weld, Socket Weld and Threaded.

Classified by Shape types

Pipe caps can be categorized by shape into three main types: hemispherical caps, elliptical caps, and flat/dished caps. Hemispherical caps offer the highest pressure-bearing capacity due to their deepest curve and most uniform load distribution. Elliptical caps are the most common standard caps in piping systems, though weaker than hemispherical caps but cheaper. Flat/dished caps, however, are suitable for low-pressure or temporary containment scenarios due to their ease of manufacture and lowest cost.

Hemispherical Cap

The depth of the hemispherical head’s curve is equal to the pipe radius. This evenly distributes stress, achieving the highest design pressure rating for a given wall thickness. Applicable standards include ASME VIII Division 1 and EN 13445.

Hemispherical heads are manufactured using a pot-forging or hot spinning process. The hot-formed head surface is typically sandblasted or shot-blasted to enhance the adhesion of the anti-corrosion coating. Available materials include ASTM A105 carbon steel, ASTM A182 F304/316 stainless steel, or high-temperature alloys.

Elliptical Cap

The ellipsoidal head has a major-to-minor axis ratio of approximately 2:1, and its depth is approximately one-quarter the pipe diameter. Its pressure-carrying capacity is 80–90% that of a hemispherical head, while material consumption is reduced by 25–30%. The dimensions and tolerances of this type of head strictly adhere to ASME B16.9 (butt-weld fittings) and EN 10253-2 (welded fittings).

The production process typically involves step-by-step deep drawing or hydrostatic forming, followed by annealing. After stamping, welding procedures are certified to ASME Section IX and tested for compatibility with NACE MR0175.

Flat/Dished Cap

Flat-bottom or concave heads offer a simple planar structure and low manufacturing cost, but their pressure resistance is only 20–40% of that of ellipsoidal heads. Their dimensions are often designed based on EN 1092-1 (slip-on flanges) or ASME B16.5 (pipe flanges and flange accessories).

After shearing or laser cutting, these plates are cold-bent or stamped, and can be electrophoretically coated or epoxy-painted for enhanced corrosion resistance. Because their pressure ratings are typically limited to PN 10–PN 16 or Class 150, they are often used for quick-sealing solutions in building plumbing, HVAC terminals, pipe purging, and temporary sealing.

Classified by Material Types

According to the valve body material, it has stainless steel, carbon steel and alloy steel elbow.

Stainless Steel pipe cap

Material Characteristics: Iron-based alloys with ≥10.5% chromium, forming a self-repairing passive oxide layer. Subtypes vary by crystal structure (austenitic, ferritic, etc.) and alloying elements (Ni, Mo, N) for enhanced corrosion/heat resistance.

| Subtype | Standard & Grade | Key Advantages | Application Directions |

|---|---|---|---|

| Austenitic (304) | ASTM A403 WP304 | Universal corrosion resistance | Food processing, architecture, chemicals |

| Austenitic (316) | ASTM A403 WP316 | Superior chloride resistance | Marine, pharmaceutical, coastal plants |

| Duplex (2205) | ASTM A815 UNS S31803 | High strength, stress corrosion res | Offshore, chemical processing |

Carbon Steel pipe cap

Material Characteristics: Primarily composed of iron-carbon alloys (C ≤ 2.1%), with trace elements like Mn, Si. Exhibits good mechanical strength and ductility but limited corrosion resistance. Properties vary by carbon content and heat treatment.

| Subtype | Standard & Grade | Key Advantages | Application Directions |

|---|---|---|---|

| Low-Carbon Steel | ASTM A234 WPB, WPC | Cost-effective, high weldability | Water, oil, gas pipelines (low/medium pressure) |

| Forged Carbon | ASTM A105 | Uniform structure, high strength | Flanged systems, valves, fittings |

| Low-Temp Carbon | ASTM A350 LF2 | Impact resistance (-46°C) | Cryogenic storage, LNG systems |

Alloy Steel pipe cap

Material Characteristics: Carbon steel enhanced with elements like Cr, Mo, Ni, V (total alloying ≤10%). Combines high strength, toughness, and temperature resistance through microstructure control (e.g., tempered martensite).

| Subtype | Standard & Grade | Key Advantages | Application Directions |

|---|---|---|---|

| Inconel® (625) | ASTM SB564 UNS N06625 | Extreme oxidation resistance | Aerospace, gas turbines, nuclear reactors |

| Monel® (400) | ASTM SB366 UNS N04400 | Resistance to acids & seawater | Marine engineering, sulfuric acid systems |

| Hastelloy® (C276) | ASTM SB366 UNS N10276 | Pitting/chloride corrosion res | Pollution control, chemical reactors |

Material Selection Guide

| Environment/Service | Stainless Steel (ASTM A403 WP304/316) | Carbon Steel (ASTM A234 WPB) | Alloy Steel (ASTM A182 F11/F22) |

|---|---|---|---|

| Corrosive (marine, chemical) | Excellent – Austenitic SS (e.g. 304/316) forms a protective Cr-oxide layer, giving outstanding corrosion resistance; typical fittings: ASTM A403 WP304/316. Weldable (be careful of chloride pitting in 304, use 316 for chlorides). | Poor – Prone to rust and pitting in wet/chemical environments; requires coatings or cathodic protection. Typical: A234 WPB (coated/painted steel caps). | Good – Chrome-Moly steels (e.g. A182 F11/F22) contain Cr/Mo for improved corrosion resistance. Better than plain carbon but less inert than stainless. |

| High Temperature | Good – Austenitic SS retains strength and ductility at elevated T (suitable up to ~800°C for 304/316L; 321/310S available for higher T). Good oxidation resistance in air. | Fair – Ordinary carbon steel softens above ~400–500°C; strength drops and scaling occurs. Used only for moderate heat. Typical: A234 WPB for 200–300°C service. | Excellent – Cr-Mo alloy steels (e.g. A182 F11, F22 or A234 WP11/WP22) are designed for high-T/high-P. High creep/rupture strength; Cr/Mo additions greatly improve oxidation resistance. |

| Low Temperature | Excellent – Austenitic SS stays ductile even at cryogenic temps (tensile strength increases at sub-zero). Low-T grades: 304L/316L (ASTM A403 WPL6/WPL9). | Poor – Standard carbon steel becomes brittle at low T, risking fracture. Special low-temp carbon (e.g. ASTM A350 LF2) must be used for cryogenic service. | Fair – Ferritic Cr-Mo alloys generally lose toughness in extreme cold. Some low-temp alloy steels (e.g. ASTM A420 WPL3) exist, but often austenitic SS or low-temp carbon steels are preferred. |

| High Pressure | Good – Stainless (especially duplex or high-Ni alloys) has good pressure capacity; however, yield strength is typically lower than carbon steel. Common: 316L, duplex 2205 (ASTM A403/A182). | Excellent – Very high strength; widely used in HP pipelines and reactors. Typical: A234 WPB caps (from A106 GrB/A105 material) or seamless A106 GrB pipe caps. | Excellent – Alloy steels (F11/F22, WP11/WP22) have very high strength and toughness, ideal for very high pressures (e.g. boiler superheater caps, high-pressure steam). |

| General Industrial Use | Good – Chosen when corrosion resistance or hygiene is needed. Common grades (304/316) weld readily (with precautions). Moderate cost. | Excellent – Default choice for general piping (cost-effective, readily available). Excellent weldability in low-carbon grades. Very versatile. | Good – Used when extra strength, toughness or temperature rating is needed. Many grades available (e.g. F5/F9/F91 for HP steam), but higher cost means not used unless required. |

| Underground/Buried | Good – Excellent resistance to soil and groundwater corrosion. 304L/316L (A403 WPL6/WPL9) often used for buried lines. | Poor – Susceptible to soil moisture corrosion. Requires heavy protective coatings or cathodic protection in pipelines. | Fair – More resistant than plain carbon (Cr/Mo offers some protection), but not as inert as stainless. Usually requires coating/cathodic measures in buried service. |

| Cost-Sensitive Projects | Poor – Highest material and fabrication cost (especially nickel-containing grades). | Excellent – Lowest cost and very common. Simplest fabrication and welding. | Poor – Expensive alloy content and heat treatment. Used only when performance merits the cost. |

Customized Pipe Cap Process

The following options are for you to customize. If you don’t have a design drawing, you can also consult our engineers and let us help you draw it.

size

Specified pipeline size, including pipe elbow direction angle, thickness, bolt hole diameter, bolt hole distance, etc.

Material

Using specified material suitable for pipeline engineering according to your requirements.

Shape

can be customized with pipe elbow such as Reducing Elbow.

Connection

Butt Weld Elbows, Socket Weld Elbows, Threaded Elbows, etc., which can be selected.

Special Treatment

Special treatments such as surface coatings and anti-corrosion can be made according to your needs.

The customization process for Pipe Cap is generally as follows:

requirements

Confirmation

Communicate in detail to determine the requirements for pipe elbow size, material, pressure, connection method, etc.

Raw Material Preparation

Cut pipe to dimensions on process card using CNC cutting machines (±1mm tolerance). Remove burrs, scale, and debris from cut ends. Grind pipe ends smooth.

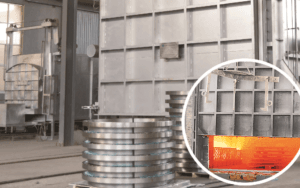

Billet Pre-Treatment

Spray internal coating lead powder graphite binder solution 0.2-0.3mm thickness dry in 120C oven for two hours

Hot Push Bending

Install mandrel die heat tube via medium-frequency induction to 750±10C hydraulic push at 50-80mms with 300-500t force

Post Forming Processing

Cool via air mist mixture control 50-80Cmin rate lathe machine ends ensure wall uniformity bevel 375±25deg

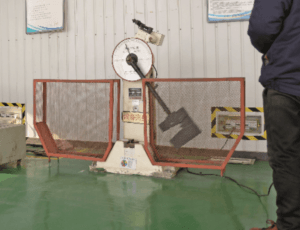

Quality Inspection

Check surface defects verify dimensions with calibrated gauges perform 100 percent MT and UT nondestructive testing

Surface Treatment

Shot blast using cast steel shot achieve SA25 cleanliness apply epoxy primer and polyurethane topcoat at specified thickness

Packaging Storage

Protect ends with plastic caps separate elbows with foam spacers include certificates store in dry ventilated warehouse

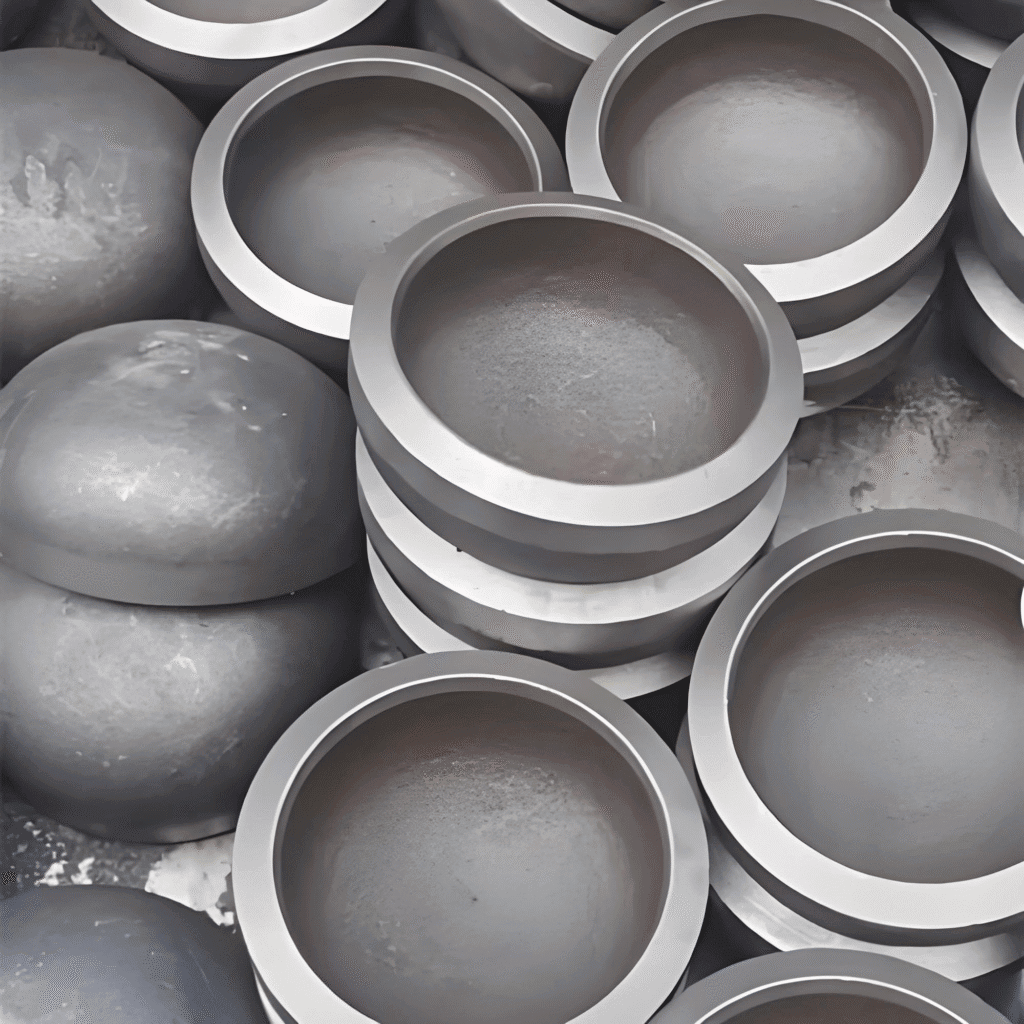

Image Gallery

Here are various Pipe Cap produced by YANHAO. You can click on the pictures to enlarge them. As a company with 25 years of Pipe Cap production experience, YANHAO supports all types of Pipe Cap production.

Pipe Cap Image Gallery

FAQs About Pipe Cap

About YANHAO

YANHAO is a China Flange Manufacturer located in Hebei Province, China. It is one of the few professional Flange suppliers in China.

We have many years of experience in flange production and have multiple flange production lines. We have sufficient stock of raw materials, rich inventory, fast delivery, and can ship within three days. At the same time, the price is affordable. You are welcome to consult and purchase!

In addition, we can provide a variety of customized flanges and pipe fittings. Customers can give drawings or samples, and our company will produce them to fit your specific requirements.

Our company was founded in 2000 and has more than 300+ employees, including 85+ middle and senior engineering and technical personnel. Our company has several production lines and covers an area of 150,000 square meters and a building area of 30,000 square meters.

300+

Number Of Workers

85+

Mid&Senior Engineers

150,000

Square Meters of Area

25+

Years of Experience

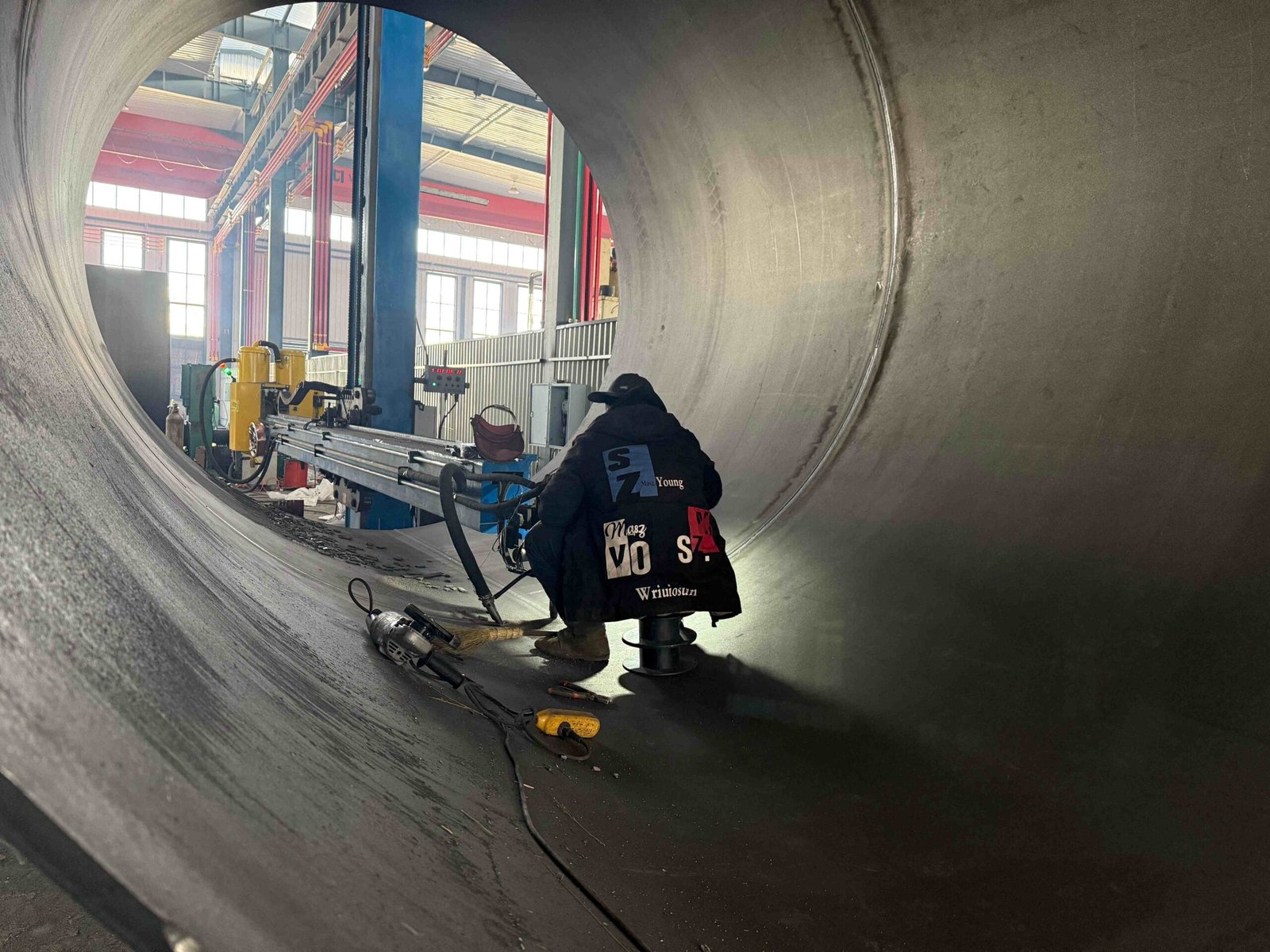

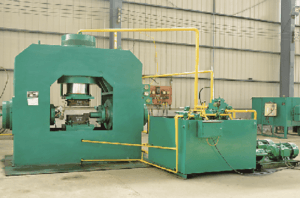

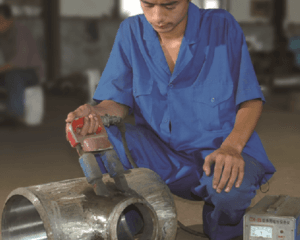

Our Production Line

Our company has 8 pipe fitting production lines and 5 flange production lines. It has a full set of medium-frequency elbow hot-pushing machines, hot-die presses for reducers, cold-extrusion hydraulic presses for tees, forging hammers, vertical lathes, drilling machines, and other process-forming and mechanical processing equipment.

Among them, the Φ1020 mm large-diameter medium-frequency hydraulic pushing machine, Φ1420 mm large-diameter medium-frequency bending machine, and Φ2438 mm 4,000-ton large hot-die press have an annual production capacity of more than 80,000 tons.

8

Pipe Fitting Production Lines

5

Flange Production Lines

80,000 tons

Annual Production Capacity

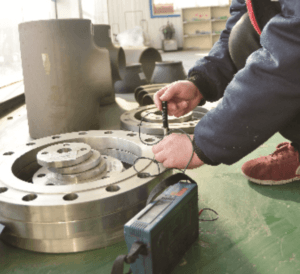

Quality Testing & Certificates

Our company is also equipped with a full set of physical and chemical testing, including spectrometer direct reading, non-destructive testing, heat treatment, water pressure testing, and other product quality testing equipment, providing a reliable guarantee for the production of high-quality products.