Lap Joint Flanges: Everything You Need to Know

A lap joint flange stands out with versatility, practical design, and corrosion resistance ability among the wide variety of flanges. Most importantly, this flange type is essential for piping systems, which are subjected to frequent repair and maintenance. Additionally, its quick bolt-hole alignment fascinates the professionals.

Following these, Yanhao’s experts are keen to inform more about the superiorities of this flange type. This article explores every aspect of lap joint flanges to assist industry professionals, designers, piping system engineers, etc., in selecting the right flange. Let’s dive into the details.

What are Lap Joint Flanges (LJ)?

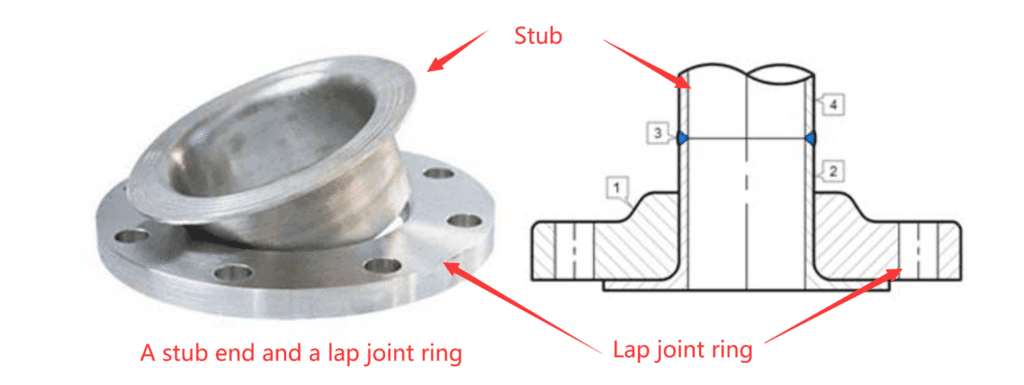

As per the core, a lap joint flange consists of two components: a stub end and a lap joint ring flange.

The stub end is a small pipe-shaped portion at the lap joint end. In the assembly process, the respective stub end is slid into the flange ring’s bore. Then, the stub end is joined to the pipe through butt welding.

Most essentially, the formed assembly’s flange ring can be rotated to inherit perfect alignment with the mating flange.

Along with the flange ring’s rotation, the LJ flange showcases another feature: reduced contact with the following substances in the piping system.

By best made in China lap joint flanges, top quality with best price >>

Core Characteristics of a LJ Flange

The following are the most essential characteristics of a lap joint flange.

- It is a two-component assembly consisting of a stub and a loose backing flange.

- The backing flange is not welded, facilitating easy installation.

- The stub is a short pipe connected to the main system’s pipe through welding.

- The flange face can be raised or flat as per design requirements.

- A lap joint flange can withstand low to moderate pressure.

Construction Materials of Lap Joint Flange

The below-listed flange materials are generally used to manufacture lap joint flanges.

- Carbon steel grade ASTM A105, A350 LF2, etc.

- Stainless steel grade ASTM A182 F304, F304L, F316, F316L, and F321.

- Alloy steel grade ASTM A182 F11, F22.

- Nickel alloys like Inconel, Monel, and Hastelloy.

- Duplex stainless steel 2205 and Super Duplex stainless steel 2507.

- Brass and bronze in copper alloy criteria.

- And many more.

Advantages and Disadvantages of Using Lap Joint Flanges

The following describes the competitive advantages and disadvantages of using a LJ flange in a system.

Types of Lap Joint Flanges

There are three types of lap joint flanges: Type A, Type B, and Type C. The following are the details.

Type A LJ Flanges

The type A LJ flange features type A stub ends with standard-length stub ends. For instance, a Type A LJ flange made of ASTM A105 carbon steel and a nominal pipe size of 2 inches with schedule 40 inherits the following:.

- The outer diameter is 2.375 inches.

- The wall thickness is 0.216 inches.

- The lap thickness is the same or greater than 0.216 inches.

- The outer corner radius follows the design.

It is to be mentioned that the stub end construction follows ANSI/ASME B16.9 while the forged steel fitting follows the standard of MSS SP-43.

Type B LJ Flange

The type B LJ flange holds type B stub ends along with a long-length stub end. Considering a 1-inch schedule 40 carbon steel pipe, the Type B Stub End is made of ASTM A105 carbon steel. The end portion is joined with the pipe via welding.

It is to be mentioned that the type B LJ flange acts like a slip-on flange. However, considering the given parameters, the respective lap joint flange inherits the following:.

- The commonly used construction materials are carbon steel ASTM A105, stainless steel ASTM A182, and alloy steel.

- The nominal pipe size ranges from 0.5 inches to 24 inches.

- Common schedules significantly vary depending on design and practical application requirements, which include 40S, 80S, and 160S.

- Type B Stub incorporates ASME B16.9 or MSS SP-43.

- Lap thickness is proportional to the wall thickness of the pipe.

- The inner corner shape is square.

- In terms of outer corner radius, a 2-inch and 150-pound class lap joint flange’s outer corner radius is 0.25 inches.

Type C Lap Joint Flange

The assembly of the type C lap joint flange consists of a type C stub end, which is custom machined. This LJ flange type is crucial as it is not only used in connecting pipes but also in attaching slip-on flanges. In the case of space limitation, the Type C lap-joint flanges are used prominently.

To provide an ideal example of type C LJ flange, the following are the most mentioned:

- First, the material is ASTM A105 carbon steel.

- Second, the standard nominal pipe size is 2 inches, and the schedule is 40.

- Third, the respective LJ flange’s outer diameter is 2.375 inches.

- The wall thickness is 0.25 inches.

- The associated lap thickness is 0.162, which is 75% of the wall thickness.

- The outer corner radius is smaller than Type A but larger than Type B.

- Its shape of the inner corner is rounded.

Applications of Lap Joint Flanges

The following are the most important applications of lap joint flanges.

Oil and Gas Industries

- In the low-pressure pipe networks.

- Following the corrosion resistance capability, the respective LJ flanges are used in crude oil processing plants.

Chemical Industry

- Lap joint flanges are widely used in piping systems, which are designated to transport various chemicals and hydrocarbons.

Power Plants

- LJ flanges are used in the piping networks that transport steam, water, and fuel.

- Due to the offered reliability and safety, LJFs are used in the nuclear plant’s critical piping system, allowing frequent maintenance works.

Other Industries

Lap joint flanges are also widely used in marine, food & beverage, and paper industries piping systems.

Choosing the Right Lap Joint Flange: Type A, B, and C

This section guides you in selecting the proper lap joint flange type.

Selecting Criteria of Type A LJ Flange

In general, type A LJ flanges are used in low-pressure environments, which require cost-effectiveness and greater reliability. Following ASTM B16.5, the matters that should be considered are listed below.

- Class 150 is required.

- For the general environment, carbon steel ASTM A105 is used, while stainless steel ASTM A182 needs to be used for the corrosive environment.

- The standard nominal pipe diameter is 2 inches.

Selecting Criteria of Type B LJ Flange

In the selection process, the type B LJ flange can be selected using the measures below.

- Applications encounter moderate pressure and temperature.

- If the piping system demands precise alignment and tight connections.

- Pressure rating can range from Class 150 to Class 1500.

- Imposing a buttweld is the requirement.

- The prominent use of SS steel and alloy steel.

Selecting Criteria of Type C LJ Flange

To select a type C lap joint flange, a professional must know that the flange is compatible with both lap joint stub ends and slip-on stub ends. It can be used in low- to moderate-pressure environments. The professional must consider the points below.

- Type C LJ flange can withstand low vibration in comparison to its other two counterparts: Type A and Type B.

- In terms of leak resistance capability, the type C LJ flange shows degraded characteristics.

- The use of type C LJ flange demands frequent replacement and repair work.

- Its pressure rating ranges from Class 150 to Class 900.

Yanhao’s Mastery in Lap Joint Flange Manufacturing

YANHAO, a well-recognized Chinese flange manufacturer located in Hebei, China, is prominent in lap joint flange manufacturing. With 5 flange production lines, an 80K ton annual production capacity, and over 300 professionals, Yanhao-produced LJ flanges are highly desirable among worldwide businesses and individuals.

The reasons behind the higher popularity of YANHAO’s products are cost-effective solutions, precise outcomes, strict deadline maintenance, and so on. It also supports businesses with customized LJ flange requirements.

In short, YANHAO is an all-in-one solution for flanges, pipe fittings, etc. Most importantly, the company’s customer care unit is active 24/7 to listen to the customers’ needs and requirements towards providing lucrative solutions.

Final Words

We hope our elaboration of every aspect of lap joint flanges will help industry professionals, engineers, designers, etc. enormously. By considering the piping system’s criteria and functionalities, the stakeholders must choose the right type of LJ flanges.

Finally, choosing the right type of lap joint flange demands careful evaluation of operating conditions, industry standards, and long-term system goals.

Other Types of Flanges

Weld Neck Flanges (WN)

WN flange, also known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, the rim, is fitted around the circumference.

China welding neck flange products >>

Slip-on Flanges (SO)

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

China slip-on flange products >>

Socket Weld Flanges (SW)

Socket Weld Flanges (SW) are similar to Slip-on Flanges (SO). The difference is that there is an extra piece in the middle.

China socket weld flange products >>

Blind Flanges (BF)

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints.

China blind flange products >>

Lap joint flange (LJ)

Consisting of two components: a stub end and a lap joint ring flange. The respective stub end is slid into the flange’s bore, and the stub end is joined to the pipe through butt welding.

China lap joint flange products >>

Threaded Flanges (TF)

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe. The installation does not involve welding

China threaded flange products >>

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.