Slip-On Flanges: Types, Uses, and Installation Guide

From HVAC systems to chemical plants’ pipelines, all accommodate slip-on flanges to meet the required strength and reliability. Slip-on flanges (also can be called SO flanges) offer cost-effective solutions for industrial systems with low pressure and fewer risks of leakage. This line triggers misconceptions among professionals, who assume that slip-on flanges are not that important.

However, Yanhao’s experts strongly argue that slip-on flanges are more than essential in numerous systems. To support this statement, we intend to elaborate on various aspects of the slip-on flange in terms of the installation process, types, uses, and benefits. The associated explorations eliminate the earlier-mentioned misconception and assist professionals in selecting the right flange.

Understanding Slip-On Flanges

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

As per the core, a slip-on flange’s internal diameter is a bit larger than the diameter of the respective pipe. The increased diameter allows the flange to slip, or can be said to slide onto the pipe. Following this phenomenon, no welding is required to form the flange-pipe joint.

Still, to ensure the respective system’s durability and reliability, many designers and professionals suggest welding inside and outside of the flange-pipe joint is essential. In this case, fillet welds are generated.

Regarding the design features, the following are the must-mentions.

- The rim of the slip-on flange accommodates bolt holes, which facilitate secure attachment to other flanges and equipment.

- A slip-on flange’s flat face is compatible with various gaskets.

- If flange-pipe joints are made of welding, these ensure superior strength and durability.

Key Characteristics of Slip-On Flanges

Below is the list of key characteristics of SO flanges.

- Flat face, low-profile hub, and no neck.

- A standard SO flange’s pressure rating ranges from 150 lbs. to 2500 lbs.

- The bore diameter ranges from 0.5 inches to 60 inches in general.

- A slip-on flange’s manufacturing and installation costs are less than the other flanges.

- Highly compatible with low- to moderate-pressure environments.

Construction Materials of Slip-On Flanges

The following are the highlighting points.

- Carbon steel is a commonly used construction material in SO flanges.

- Stainless steel grades 304, 316, 316L, etc. are also used.

- Alloy steel grades A182 F1, F5, F9, F11, etc. are used.

- Another core construction material of slip-on flanges is Duplex Stainless Steel with grade UNS S31803.

Types of Slip-On Flanges and Applications

The types of SO flanges are divided into two segments based on flange face and welding types.

Slip-On Flange Types based on Face Types

Below are the details.

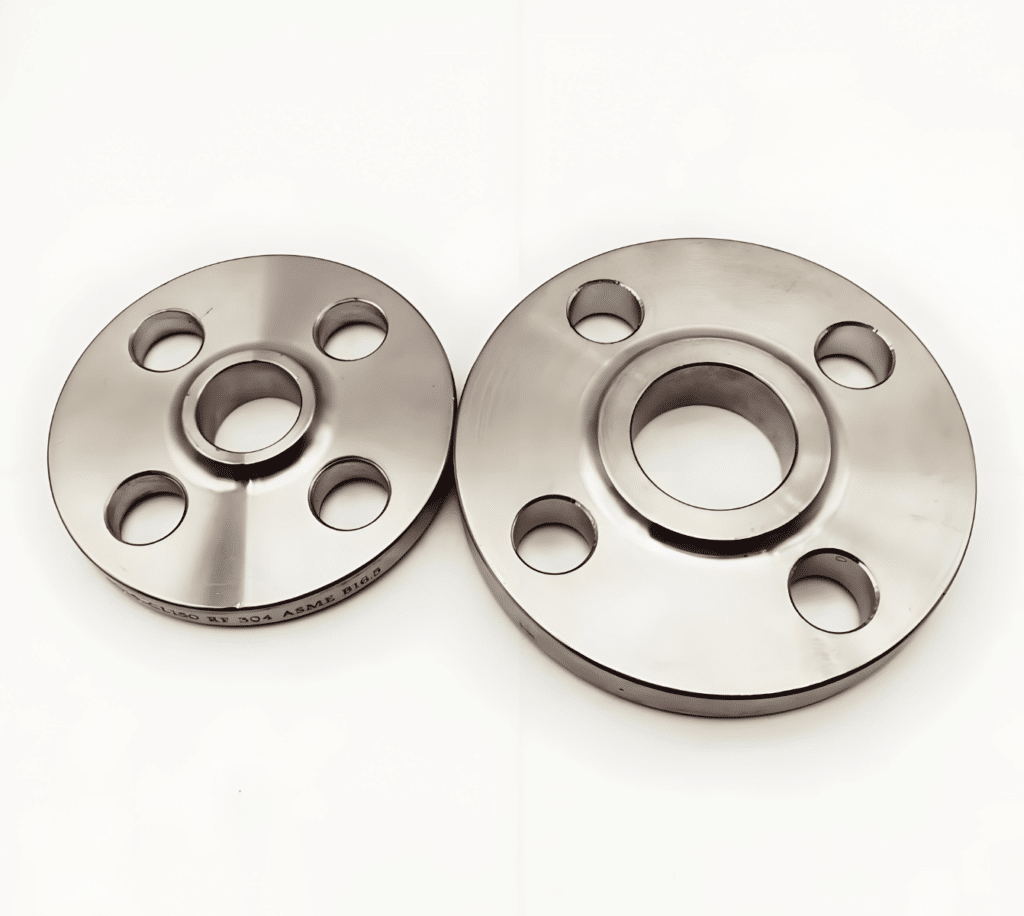

Standard SO Flanges

It inherits a flat face with a pressure rating of 150–2500 lbs. Standard slip-on flanges are used in low- to moderate-pressure environments. To use it perfectly, in the case of incorporating welding, professionals keep a little extended portion of the pipe, which ensures perfect flange-pipe welding.

Applications

- Zero or low-pressure gas or water piping systems.

- Joining components in chemical plants.

- Connecting pipes of an HVAC system.

- In the food and beverage industry, standard SO flanges are used in piping systems designated to transport milk and juice.

- A wide variety of uses are found in general household piping systems.

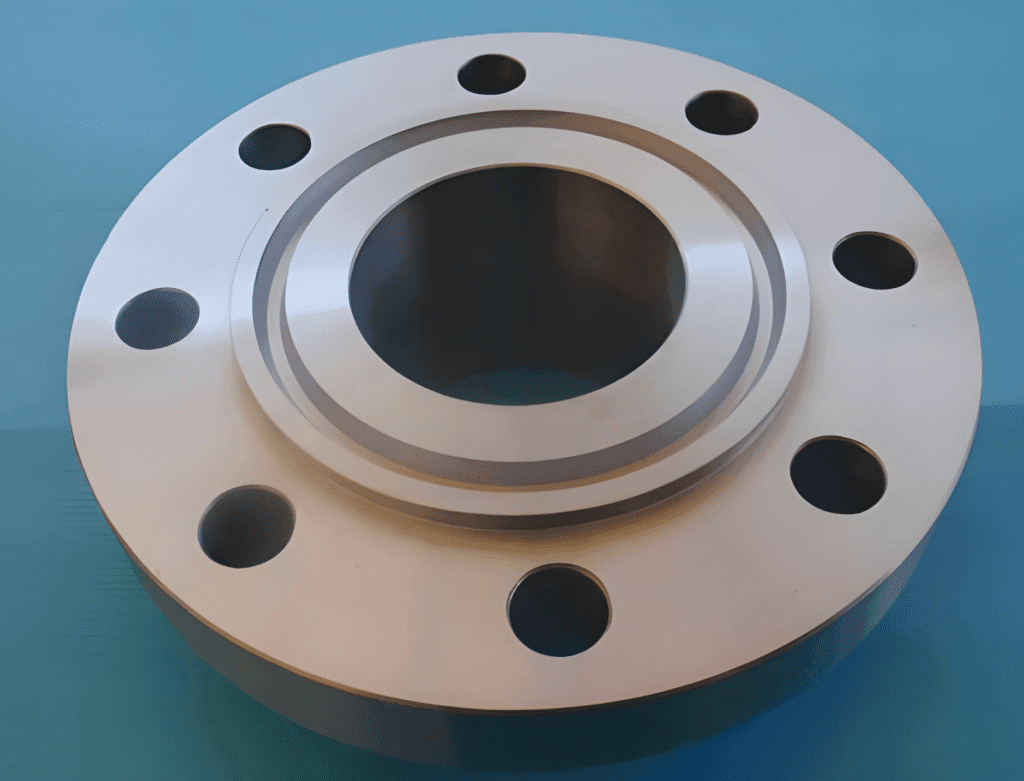

Raised-Face SO Flanges

The raised-face slip-on flange accommodates a circular extruded portion surrounding the bore of the flange. This design component is suitable to fit the gasket, enhancing its pressure tolerance capability.

As the design pressure of the respective system increases, the flange manufacturers raise the portion more. As per ASNI/ASME B16.5, a raised-face SO flange’s pressure rating ranges from 150 to 2500 lbs.

Applications

- SO flanges are used in the oil and gas industry piping systems where space constraints do not allow the installation of weld neck flanges.

- In the chemical processing plants’ systems, to restrict corrosion, SS or alloy steel RFSO flanges are used.

- RFSO flanges are used in power plants where pressure and temperature are moderated.

- Raised-face SO flanges are used to divert the liquid and gas flow.

RTJ SO Flanges

A ring-type joint SO flange hosts a small groove on the raised portion, which is generated by precision machining. The groove is used to hold the gasket ring tightly, enhancing the sealing’s ability. As mentioned earlier, the pressure rating of RTJ SO Flanges ranges from Class 150 to Class 2500.

Applications

- RTJ SO flanges are used to connect pipes that are designated to transport oil, gas, chemicals, etc.

- In the power generation industry, RTJ slip-on flanges are used to connect boilers, valves, condensers, etc. to the systems.

- In the highly corrosive environments’ piping systems, RTJ SO flanges are used.

Slip-On Flange Types based on Welding Types

Well, as mentioned earlier, in many cases, SO flanges do not require welding. But to enhance the durability and reliability of the systems, welding plays a crucial role. Following these, the SO flanges can be divided into two categories.

Slip-On Welding Plate Flange

This SO flange type features the following:

- Flat face and no hub.

- Incorporates basic strength.

- Remarkably budget-friendly.

Applications

- HVAC systems.

- Water treatment applications.

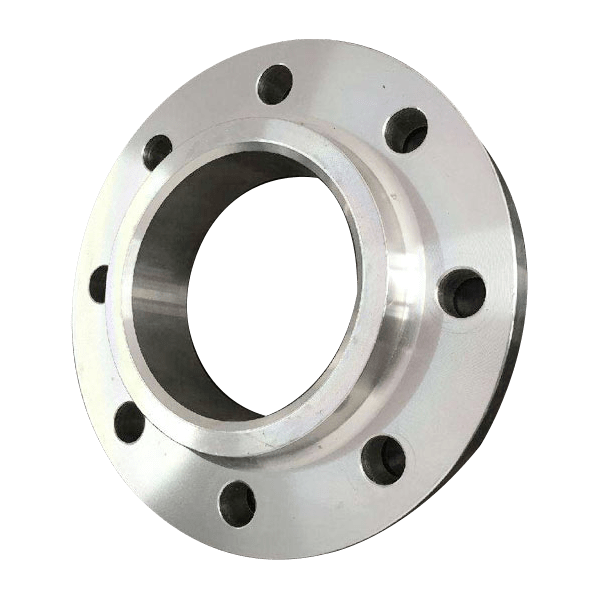

Slip-on Welding Hubbed Steel Pipe Flange

A SO WH steel pipe flange features the following:

- It hosts a hub with a raised surface.

- The hub’s diameter is larger than the pipe’s outer diameter, triggering the slip-on facility.

- Its strength is significantly high.

Applications

- In oil and gas industries, this flange type is used in moderate to high-pressure environments.

- Chemical and water transportation systems.

- In industrial applications in which cleaning and maintenance requirements are frequent.

- Fire protection systems.

How to Install a Slip-On Flange: A Stepwise Guide

The following is the step-by-step process to form the pipe-flange joint.

Preparation

The following items are required to be arranged before starting the installation work.

- Personal protective equipment.

- Pipe cutter, measuring tape, marker, wrenches, a slip-on flange, a piece of pipe of the respective system, and so on.

- Welding machine.

Make Ready the Pipe

- Measuring the pipe’s outer diameter to ensure its compatibility with the selected slip-on flange.

- Ensuring the end portion of the pipe does not host any rust, dust, etc. If there are any, those need to be removed using a hard brush and solvents.

- The edge of the pipe needs to be smoothened using sandpaper.

SO Flange Installation

- Sliding the flange over the prepared pipe end. It will be smoothly fitted if everything is good without requiring extensive force.

- Aligning the bolt holes as per the required orientation.

Welding

If the design proposes welding joints, the following need to be incorporated:

- Checking the to-be-welded areas for paint, dirt, rust, etc. If any, those need to be cleaned.

- Marking the welding spots. In this case, it is essential to maintain 40 mm to 100 mm gaps. However, the respective system’s design provides an accurate measure.

- Fillet welding must be done on the inner portion of the pipe-flange joint. Whereas tech welding must be imposed on the outside portion of the pipe-flange joints.

- Chipping and cleaning of the welds are necessary.

- Finally, a close visual inspection ensures the quality of the respective weld joints. Upon finding any dissatisfactory welding quality, the previous welding needs to be removed by a grinding machine and then redo it.

Lastly, it is to be mentioned that to form a flange-flange joint, the nuts and bolts are used while placing a compatible gasket between the two flanges.

Advantages and Disadvantages of Using Slip-On Flanges

The list below elaborates on the most important advantages and disadvantages of using SO flanges.

Advantages

- Ease of installation.

- A cost-saving solution to connect pipes and components.

- Due to enhanced versatility, SO flanges can be used in numerous applications.

- The associated compact design saves space.

- Facilitates a higher level of flexibility.

Disadvantages

- If not welded or poorly welded, leakage can occur.

- Durability is not that good.

- Inherits risks of welding defects.

Yanhao’s Mastery in Producing Slip-on Flanges

YANHAO, a pipe fitting manufacturer in Hebei, China, is globally known for its commitment to excellence, innovative manufacturing practices, diverse product range, and cost-effective solutions. With over 25 years of experience, five functional flange production units, and an annual capacity of over 80K tons, Yanhao is a prominent destination for worldwide customers’ orders of Chinese flanges.

Among other types of flanges, Yanhao showcases a superior mastery level to produce Class 150 to Class 1500 slip-on flanges of different types. State-of-the-art tools and technologies, coupled with a skilled workforce, enable Yanhao to produce customized slip-on flanges. In short, Yanhao is a trusted name for businesses and individual users who want to get high-quality slip-on flanges with accurate dimensions, material, strength, etc.

Final Words

Slip-on flanges are highly crucial components that offer reliable and cost-effective solutions to form a piping system.

We delve into the types, applications, and benefits of SO flanges to aid professionals in choosing the appropriate flange type. However, professionals should take into account the disadvantages outlined in this article to ensure strategic planning.

Other Types of Flanges

Weld Neck Flanges (WN)

WN flange, also known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, the rim, is fitted around the circumference.

China welding neck flange products >>

Slip-on Flanges (SO)

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

China slip-on flange products >>

Socket Weld Flanges (SW)

Socket Weld Flanges (SW) are similar to Slip-on Flanges (SO). The difference is that there is an extra piece in the middle.

China socket weld flange products >>

Blind Flanges (BF)

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints.

China blind flange products >>

Lap joint flange (LJ)

Consisting of two components: a stub end and a lap joint ring flange. The respective stub end is slid into the flange’s bore, and the stub end is joined to the pipe through butt welding.

China lap joint flange products >>

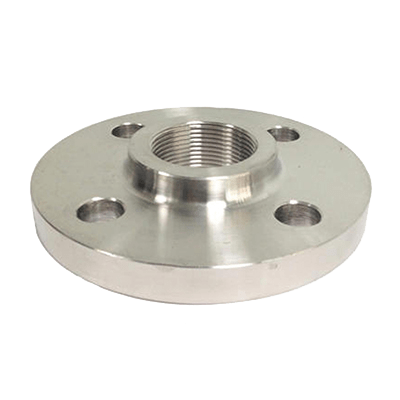

Threaded Flanges (TF)

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe. The installation does not involve welding

China threaded flange products >>

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.