Understanding Weld Neck Flanges: Types and Applications

To ensure leak-proof connections in high-temperature and high-pressure environments, weld neck flanges are the most considerable option. With a long-trapped hub and superior strength, a weld neck flange also ensures structural integrity and efficient operation.

Wait, not only these, but there is also more to know about this flange type towards maximizing its usability-related potentials. In this blog post, Yanhao’s experts intend to provide some crucial information and data in terms of understanding weld neck flanges. This blog also explores the types and applications of this faucet type.

Understanding Weld Neck Flanges

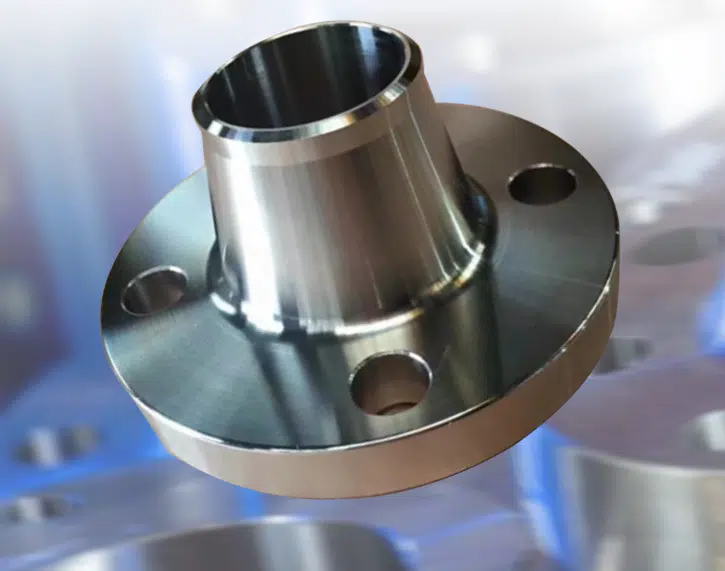

A weld neck flange (or welding neck flange, WN flange), also widely known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, i.e., the rim, is fitted around the circumference.

Here, the trapped neck of the weld neck Chinese flange gradually extends from the flange face towards the pipe base. This extended portion is designated to reduce the pressure at the bottom portion of the flanges during the fluid or gas flow. The end of the extended portion is adjoined with the pipe’s end through imposing butt joints.

Key Characteristics of Weld Neck Flanges

The following are the core characteristics of this flange type.

- The long-trapped hub of a weld neck flange triggers equal stress distribution across the flange-pipe connection.

- The extended neck ensures greater structural integrity.

- The structural design of this flange type ensures an obstruction-free flow of liquids and gases.

- Its design assists in minimizing turbulence while reducing the possible orientation of erosion.

- The associated flange-pipe joint is termed a ‘butt-weld joint,’ which ensures almost zero leakages.

Materials Used in the Construction of High-Hub Flanges

Below are the most used construction materials for weld neck flange, along with the general using criteria.

- Carbon steel WN flanges are for standard industrial piping systems.

- Alloy steel weld neck flanges are used in applications that require higher strength and durability.

- Stainless steel-made WN flanges are used in highly corrosive environments.

- Duplex Steel WN flanges provide high strength and excellent corrosion resistance facilities.

- High-hub flanges made of nickel alloys are suitable for extreme temperatures and corrosion resistance.

Competitive Advantages of Using WN Flanges Over Others

The following are the most crucial competitive advantages.

- Ensures greater resistance to high pressure and temperature than other flange types.

- Due to having butt-weld joints, a WN flange facilitates a higher degree of leak-proof context.

- The associated smooth transition between pipe and flange restricts the orientation of crakes and even system failure.

- A WN flange provides superior resistance to thermal expansion, contraction, and mechanical forces.

- Weld neck flanges are considered versatile due to their greater compatibility with a diverse range of pipe materials.

- WN flanges effectively incorporate international standards like ASTM, ANSI, etc.

- Using weld neck flanges facilitates reduced replacement, repair, and maintenance requirements.

Types of Weld Neck Flanges

The weld neck flange type is segregated into two segments based on face and extended potion types. The following are the in-detail discussions.

Weld Neck Flange Type Based on Extended Portion Criteria

There are three WN flanges in this criteria.

Long Weld Neck Flanges

Long WN flanges are also termed ‘standard weld neck flanges.’ It comes in various dimensions. For instance, as per ASME B16.5, a ½ long WN flange’s OD is 3.5, thickness is 0.44, barrel OD HB diameter is 1.5, bolting is 4 nos of holes, and RF length is 21/4. This falls in Class 150 Standard Connections WN Flange.

On average, one long WN flange’s price ranges between $2.07 and $10.08. Most importantly, long weld neck flanges are used in specialized industrial projects that require added reinforcement.

Reducing WN Flanges

A reducing WN flange is crucial in the industrial system in which smooth transitions between different pipe sizes are necessary. The associated tapered connection ensures smooth fluid and gas flow while minimizing turbulence. It is to be mentioned that the per-piece price of reducing WN flange ranges from $11 to $16.

The following are the basic specifications of a reducing long-hub flange as per ANSI B16.5.

- The basic NPS of the flange is 8 inches x 6 inches.

- The pressure class starts at 150.

- The standard material grade is A105- Carbon Steel.

NW Long Weld Neck Flanges

NW long weld neck flanges, also known as ISO-KF long neck flanges, are prominently used for experimental purposes. This WN flange type provides leak-tight sealing under vacuum conditions. The following is a standardized example for a NW long WN flange as per DIN 28403.

- The nominal size of the flange is NW 25, which represents 25 millimeters.

- Raised face.

- Material type: 316L Stainless Steel.

Weld Neck Flange Types Based on Face Criteria

There are several types of WN flanges based on flange-face types. The following discussions are designated to elaborate on these considering flange-flange joints, not flange-pipe joints.

Flat Face

In this case, the rubber, metal, or fiber-made gasket ensures tight sealing between two WN flanges.

Raised Face

Its construction materials are the same as those of FF. Here, the raised face triggers an increased contact area for the gasket.

Male and Female Face

Like the connectors, the male face WN flange is joined with the female face flange, forming a tight joint. A ring gasket is usually used between the joinings to incorporate better tightening.

Tongue and Groove Face

A WN flange tongue-face is joined with the other flange’s groove face. In this case, rubber or metal gaskets are used prominently.

Ring-Joint Face

The RJF WN flange is used in creating high-pressure tolerance flange-flange joints. Here, in general, a metal ring joint gasket is used.

Lap Joint Face

In this WN flange criterion, a metal gasket ring is placed between the raised face WN flange and flat face WN flange, creating a tight seal. This WN flange type is widely used in conjunction with blind flanges for isolation purposes.

Applications of Weld Neck Flanges

The following are the applications of weld neck flanges in various industries.

Oil and Gas Industries

- Establishing long pipelines to transfer crude oil, natural gas, etc. from point A to point B.

- In the processing plants’ systems of refineries, high pressure and high temperatures are active.

- WN flanges are used in the drilling systems of offshore plants.

Power Generation

- WN flanges are used in steam and gas turbines, boilers, etc.

- Due to their higher resistiveness and strength, WN flanges are used in nuclear power plants.

Chemical Industry

- In the chemical industry’s piping system, WN flanges are used widely due to the associated corrosion resistance facilities.

- Weld neck flanges are used in pharmaceutical manufacturing processes where the piping systems encounter sterile environments.

Marine Industry

- WN flanges are used in sea vessels’ fuel distribution systems, hydraulic systems, and other critical systems.

- In offshore LNG refineries, this flange type is usually used in LNG transportation systems.

Other Prominent Industries that Use WN Flanges

- Food and beverage industries use WN flanges in the processing and packaging lines for the respective items.

- In the pulp and paper manufacturing industry, the considered flange type is used in the piping systems.

- In mining operations, WN flanges are used in slurries and other material transportation systems.

- Some of the on-ground aerospace applications use welded neck flanges to enhance the respective system’s efficiency.

Must-Consider Factors in Selecting the Weld Neck Flange

The factors are listed below.

- Nominal pipe size and flange bore size (What’s the difference between pipe size and bore size?).

- Maximum operating pressure in the going-to-be developed system.

- Maximum and minimum operating temperatures of the system.

- Selection of compatible WN flange materials.

- Appropriate selection of WN flange’s face type.

- Effective incorporation of industry standards like ANSI B16.5, ASME B16.47, API 609, and so on, depending on applicability in the region.

- A proper welding job is highly required.

Yanhao’s Expertise in Manufacturing Weld Neck Flanges

To exploit the superiorities and beneficial features of WN flanges, the flanges’ quality matters significantly. In this case, more than 400 businesses and individuals find Yanhao a high performer. YANHAO, a well-reputed Chinese flange manufacturing company located in Hebei, China, has over 25 years of experience in weld neck manufacturing, offering cost-effective product solutions.

Yanhao has 5 flange production lines and an annual production capacity of 80K. Along with these, the highly skilled and experienced professionals can deliver satisfactory outcomes in terms of quantity, quality, maintaining deadlines, etc. Above all, Yanhao’s quality-control system is considered a state-of-the-art element, ensuring each WN flange meets the design and strength-related requirements.

Final Words

Undeniably, weld neck flanges are one of the most crucial components in industrial piping systems. WN flanges offer unparalleled strength, reliability, and versatility with the associated long-tapered hubs, butt-weld joints, and optimal stress distribution.

Finally, by using the elaborations on various aspects of WN flanges, businesses and users will be able to select the right flange type as per their diverse needs while meeting local entities’ standards.

Other Types of Flanges

Weld Neck Flanges (WN)

WN flange, also known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, the rim, is fitted around the circumference.

China welding neck flange products >>

Slip-on Flanges (SO)

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

China slip-on flange products >>

Socket Weld Flanges (SW)

Socket Weld Flanges (SW) are similar to Slip-on Flanges (SO). The difference is that there is an extra piece in the middle.

China socket weld flange products >>

Blind Flanges (BF)

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints.

China blind flange products >>

Lap joint flange (LJ)

Consisting of two components: a stub end and a lap joint ring flange. The respective stub end is slid into the flange’s bore, and the stub end is joined to the pipe through butt welding.

China lap joint flange products >>

Threaded Flanges (TF)

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe. The installation does not involve welding

China threaded flange products >>

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.