What Are Threaded Flanges? A Complete Overview

Threaded flanges are necessary parts of piping systems that link pipes without welding. They are internal threads that present a practical way for systems to be broken down and adjusted from time to time.

Because they’re compatible with high-pressure environments and easy to install, they’re a favored choice across industries, including oil and gas, water treatment, and HVAC. They are known to perform reliably in a wide range of uses.

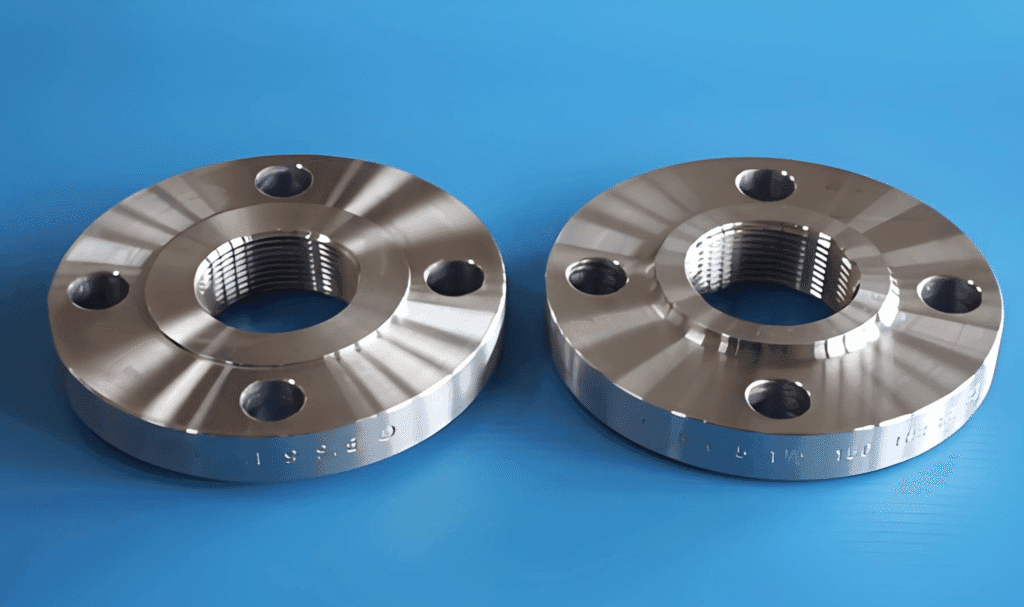

What Are Threaded Flanges?

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe.

Unlike welded flanges, the installation does not involve welding, so they could be applied well in applications viewed as hazardous with welding or even impossible.

Technical Specifications of Threaded Flanges

| Specification | Value |

|---|---|

| Thread Type | Threaded (NPT/BSPT) |

| Material | Carbon Steel ASTM A105/A105N |

| Design Standard | ANSI/ASME B16.5 |

| Pressure Class | 150#, 300#, 600# |

| Size Range | 1/8″ to 4″ |

| End Connection | Internal Thread NPT/BSPT |

| Face Finish | 125-250 AARH |

| Face Type | Raised Face (RF) |

| Temperature Range | -20°F to +800°F |

| Coating | Black Paint/Bare/Galvanized |

| Testing | 100% Hydrostatic Tested |

How Do Threaded Flanges Work?

Threaded flanges have been designed for a secure, leak-proof connection between pipes without welding. The inner threads of those pipes match the outward threads of the pipe but can be screwed tight together to form a good seal.

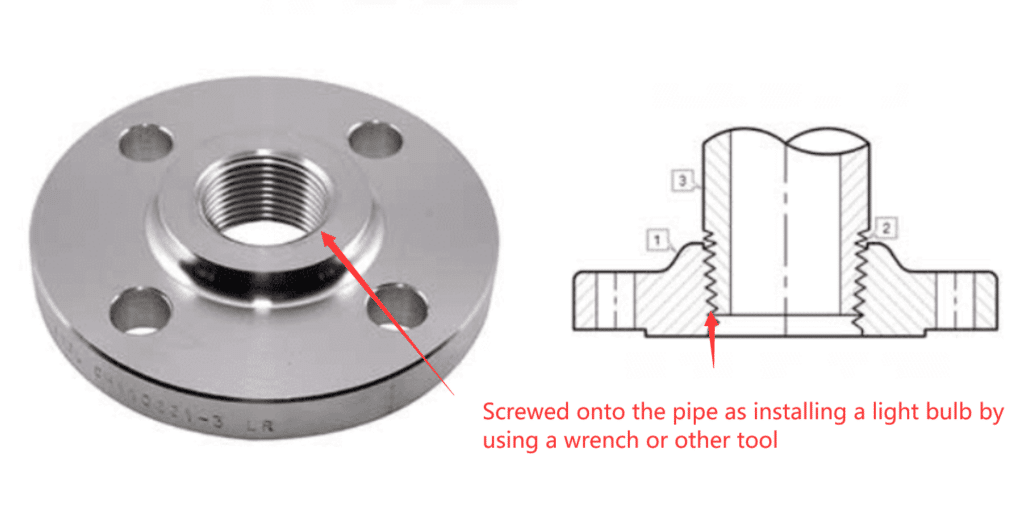

Connection Mechanism

Threaded flanges are internally threaded to accept the externally threaded pipe.

The flange is similarly screwed onto the pipe as installing a light bulb by using a wrench or other tool, creating a tight, mechanical bond.

This mechanism does not require welding, so threaded flanges are perfectly adapted for situations where welding would be difficult, such as with flammable or high-pressure lines.

Seal Formation

Sealing methods other than by virtue of the threaded connection alone are often employed to avoid leakage. Generally applied to the threads before assembling, a thread sealant might take the form of some tape, such as PTFE or liquid thread sealants. To improve leak protection in applications involving gasket flanges, especially when raised faces or RTJ type/flange faces.

Best-Suited Applications

Threaded flanges have a special advantage in the following cases:

- High-Pressure Systems: Threaded flanges are suitable for moderate to high-pressure applications, particularly in small-diameter piping.

- Hazardous Environments: Applications related to systems carrying highly flammable or hazardous media avoid the risks of the welding procedure.

- Temporary or Removable Connections: Used in setups requiring frequent disassembly or maintenance.

- Industries: Commonly found in oil and gas, chemical processing, water treatment, HVAC, and residential plumbing systems.

Types of Threaded Flanges

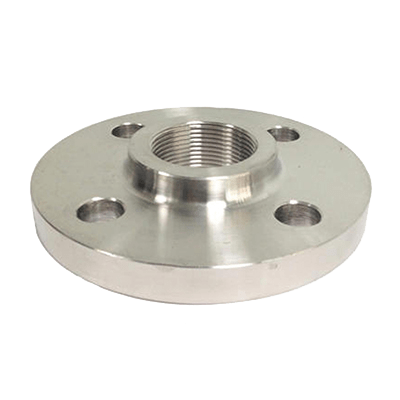

Standard Threaded Flanges

Standard threaded flanges are the most common type and are intended for general-purpose applications. The pipes have external threads that mate with their internal threading for a simple, dependable connection. These flanges are ideal for moderate-pressure systems where welding is infeasible or undesirable.

Raised Face (RF) Threaded Flanges

Raised-face threaded flanges possess a face slightly raised from around the bore. This feature enhances the sealing capability by increasing the gasket area. Raised-face threaded flanges see wide application when a strong seal is desired, especially in high pressure or high temperature.

Flat Face (FF) Threaded Flanges

Flat-face threaded flanges have a smooth, flat contact surface. They are mainly used under low-pressure applications and where the mating flange or pipe has a flat face. This flat surface ensures an even distribution of pressure across the seal and is not likely to deform the gasket.

Components and Construction of Threaded Flanges

Precision designed for industrial and residential uses, the threaded flanges meet many industry standard requirements. Building them requires various important components specialized to increase durability, compatibility, and performance. Below is a detailed breakdown:

Material Options

Threaded flanges can be made from a variety of materials for different environments and media.

- Carbon Steel: general-purpose applications where high strength and low cost are required.

- Stainless Steel: Excellent resistance to corrosion, applicable in harsh or corrosive environments.

- Alloy Steel: Used in high-performance systems, including high-temperature and/or high-pressure systems.

- Cast iron: This is usually used for low-pressure, non-corrosive applications because of its inexpensiveness.

Threading Specifications

Threading is very important for threaded flanges to ensure that the joints are perfectly tightened to avoid leakage. Some common specifications include:

- NPT (National Pipe Thread): This threading is predominantly used in North America with a tapered design, which assists in increasing sealing capability by getting tighter as the connection is screwed together.

- BSPT (British Standard Pipe Taper): BSPT threads use a taper—similar to the taper used with NPT—for securing and preventing leaks.

- ISO Threads: These threads are internationally standardized, allowing them to be used across a wide range of piping systems for global applications.

- Precision Machining: The threaded threads are designed to the precise depths and pitches to match pipe threads and provide a good, no adjustment required, tight fit.

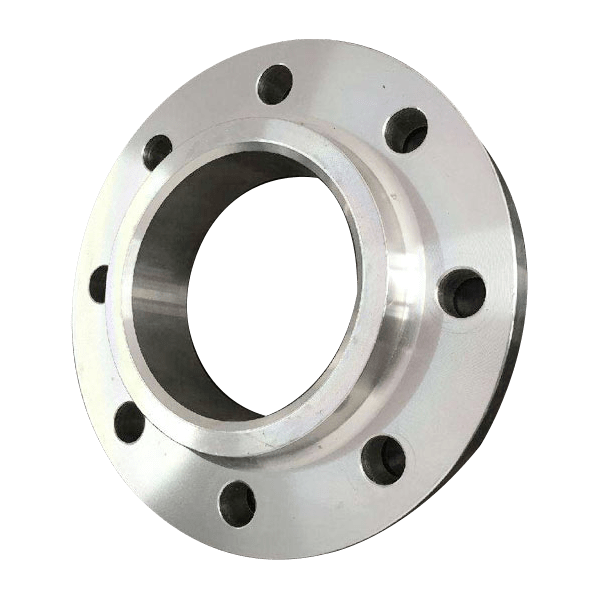

Bolt Holes and Patterns

Bolt holes in threaded flanges are drilled according to specific standards to ensure compatibility and even distribution of stress.

- ASME B16.5 Standards: According to bolt hole patterns, spacing, and diameters that are consistent throughout industries.

- Patterns: The uniform pressure distribution and robust joint strength are achieved through circular bolt-hole patterns.

The amount and size of bolt holes depend on flange size and pressure rating.

Gasket Surfaces

Gasket surfaces are designed to enhance sealing between the flange and the connecting pipe.

- Smooth Machined Surface: The uniform surface for gaskets helps reduce the risk of leaks.

- Grooved Surface: Gaskets are held more securely, which is ideal for use where there are regular pressure fluctuations.

- RTJ Grooves: Specifically designed to accommodate metal ring gaskets for high-pressure systems.

Applications of Threaded Flanges

Industrial Piping Systems

Threaded flanges are important in the piping system where the fluids or gases are transported in the industrial piping systems. Since they can handle moderate-to-high-pressure conditions, they are especially used in manufacturing, food processing, and pharmaceutical industries.

Chemical Processing

Threaded flanges are used in chemical plants to join piping networks that carry corrosive or dangerous chemicals. Particularly advantageous in such environments as those where welding may be dangerous, their non-welded design adds an economy of production. Chemical compatibility and selected resistance are often selected metals like stainless steel.

Oil and Gas

Threaded flanges are mostly used in oil and gas applications such as refineries, pipelines, and offshore platforms. They ensure that connections are leakproof for high-pressure transport of hydrocarbons and other fluids. RTJ threaded flanges are particularly well suited for applications requiring excellent sealing in highly pressurized and temperature environments.

Water Treatment

Threaded flanges are used in water treatment facilities to assemble water distribution, filtration, and wastewater management pipelines. Preferred for longevity and reliability in these systems are their corrosion-resistant variants, such as stainless steel flanges.

HVAC Systems

Threaded flanges are used in heating, ventilation, and air conditioning to connect ductwork and piping. These kinds of flanges allow for the effective flow of refrigerants, steam, or air in all HVAC installations, whether commercial or residential. Their versatility allows them to adapt to varying system requirements.

YANHAO: Reliable Flange Manufacturer

YANHAO is a professional flanges manufacturer with a wide range of flanges, including threaded flanges, which are of high quality and applicable to the industries. Combining precision engineering, strict quality standards, and a commitment to durability and reliability, YANHAO guarantees durable and reliable products for use in oil and gas, chemical processing, water treatment, and many other applications.

We offer flanges in various materials and specifications, meeting the normal and custom requirements. With years of experience and excellent customer support, YANHAO has been a proven partner for all your flange needs: reliable, cost-effective, and delivering something for everyone in the product.

Wrapping Up

Threaded flanges, with their effective and non-welded connection of piping, find applications in various practical services. Their adaptability with diversified systems ensures reliable performances during unfavorable situations.

In your quest for high-quality flanges that meet the strictest standards, look nowhere else than YANHAO for solutions to address your needs.

Other Types of Flanges

Weld Neck Flanges (WN)

WN flange, also known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, the rim, is fitted around the circumference.

China welding neck flange products >>

Slip-on Flanges (SO)

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

China slip-on flange products >>

Socket Weld Flanges (SW)

Socket Weld Flanges (SW) are similar to Slip-on Flanges (SO). The difference is that there is an extra piece in the middle.

China socket weld flange products >>

Blind Flanges (BF)

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints.

China blind flange products >>

Lap joint flange (LJ)

Consisting of two components: a stub end and a lap joint ring flange. The respective stub end is slid into the flange’s bore, and the stub end is joined to the pipe through butt welding.

China lap joint flange products >>

Threaded Flanges (TF)

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe. The installation does not involve welding

China threaded flange products >>

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.