Flange Markings: Flange Identification For Quality Assurance (You will know at a glance)

Most of the flanges you see have some capital letters on each outer ring. These obvious steel stamp marks are to allow us to distinguish flanges. Different letters represent different meanings, such as different pressure values and diameters. In this blog, YANHAO will take you to understand the common flange marks and learn how to distinguish different flanges through flange marks.

Flange marking is like the ID card of the flange

Flange marking (usually steel stamp) refers to the identification content printed on the flange. This is like the ID card of the flange.

Every flange shipped from the factory should have a printed mark. You can identify the flange by the identification content and judge its model, specification, material, and other information.

Through the flange identification, the flange can be classified and categorized for better management. Secondly, during the delivery, acceptance, inspection, assembly, and maintenance of the flange, the flange must be identified, and the identification content provides such a basis.

Moreover, the steel stamp identification content can also provide quality information about the flange, which is convenient for quality control.

Detailed explanation of flange marking (You will know at a glance)

The image below is a YANHAO-made flange. We can see that the flange marking says: YH SO DN65 PN16 RF 304 HG/T20592 2009.

Through the above example, you should be able to understand the meaning of different letters in flange markings. Below I will also put some pictures of flange markings produced by YANHAO and explain the meanings of these markings, respectively. If you are interested, you can continue to check it out.

Other flange marking examples

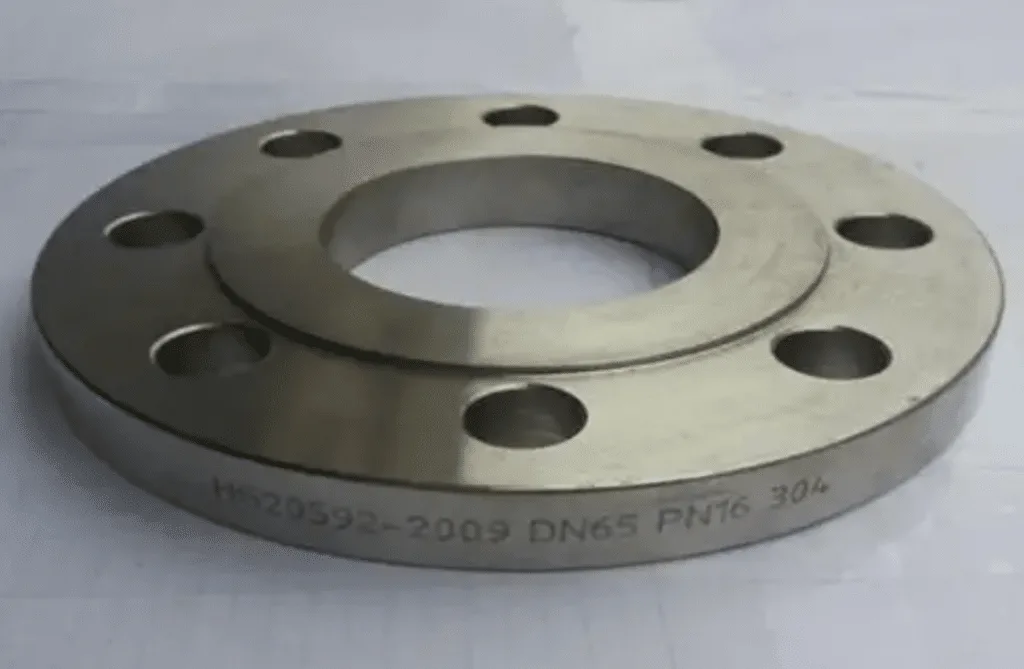

The meaning of the mark “HG20592-2009 DN 65 PN16 304” on the flange is as follows:

In summary, this mark indicates a steel pipe flange manufactured in accordance with the HG20592-2009 standard, with a nominal diameter of 65 mm, a nominal pressure of 16 bar, and a material of 304 stainless steel.

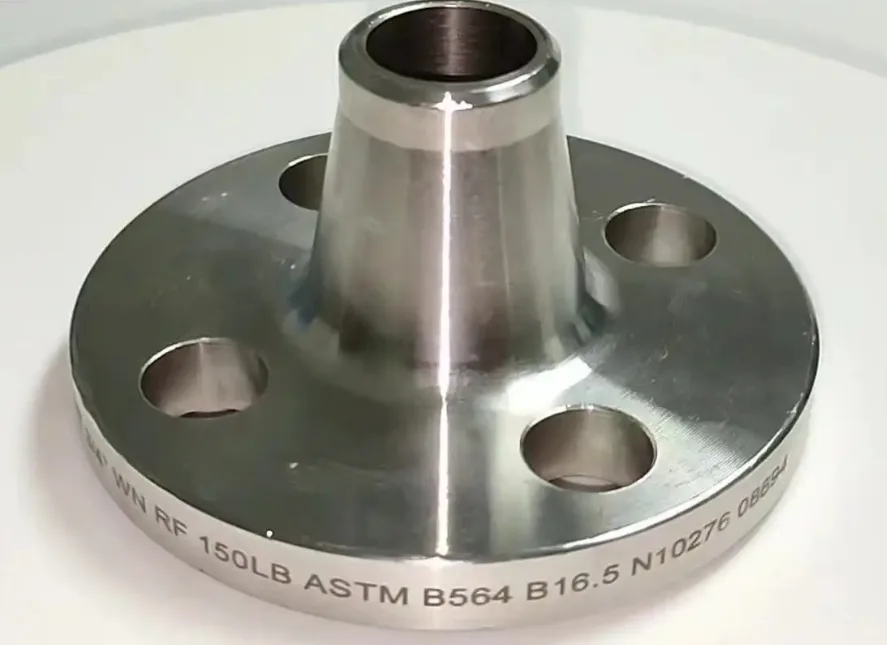

WN RF 150LB ASTM B564 B16.5 N10276. The meanings of these markings are as follows:

Overall, WN RF 150LB ASTM B564 B16.5 N10276 refers to a necked butt welding flange manufactured in accordance with the ASME B16.5 standard, with a pressure rating of 150LB and a raised face sealing surface. The material is Hastelloy C-276 and follows the ASTM B564 standard.

Final

This article details the importance of flange markings and key information on how to identify flanges through these markings. By explaining different marking codes, such as manufacturer abbreviations, flange types, nominal diameters, sealing surface forms, and material standards, the article helps readers quickly understand flange identification.

This information is essential for flange quality assurance, classification management, and identification during delivery, acceptance, inspection, assembly, and maintenance. The purpose of the article is to enable readers to quickly and accurately grasp the specifications and characteristics of flanges through the markings on the flanges to ensure the smooth, safe, and reliable operation of the piping system.

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.