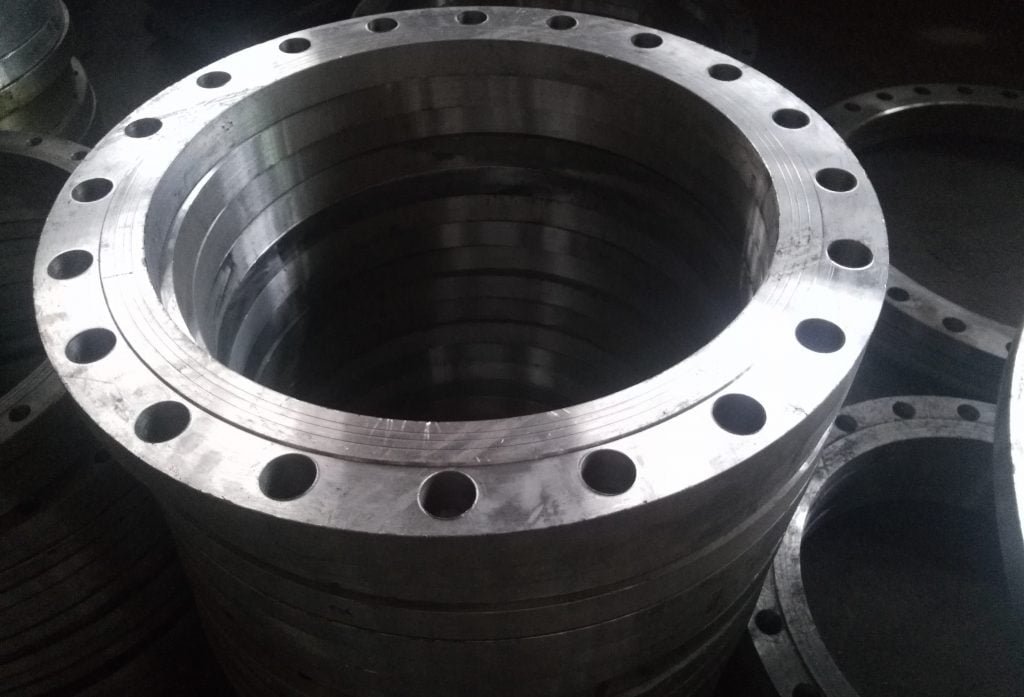

20″ Pipe Flange

Welcome to our blog! In this space, we’ll explore the world of industrial solutions, with a particular focus on the versatile and essential 20″ Pipe Flange offered by YANHAO. Join us as we delve into the precision engineering, durability, and cost-effective advantages that make this product a standout choice for industries worldwide. Discover how YANHAO continues to set industry standards with its commitment to excellence.

I. Product Specifications

Here are the detailed specifications for the 20″ Pipe Flange:

| Specification | Detailed Description |

|---|---|

| Size | 20 inches (Inches) |

| Pressure Rating | ANSI 150, ANSI 300, ANSI 600, ANSI 900, ANSI 1500, ANSI 2500 |

| Material | Stainless Steel, Carbon Steel, Alloy Steel, or other specialized alloy materials (per customer requirements) |

| Flange Type | Weld Neck, Slip-On, Blind, Threaded, Forged, Lap Joint, Threaded Neck, Socket Weld, Flat Face, or other specialized types (per customer requirements) |

| Surface Finish | Smooth, Raised Face, Concave Face, Oval, or other specialized surface finishes (per customer requirements) |

| Gasket Compatibility | Designed for compatibility with various gasket materials, including rubber, metal, graphite, and others, to ensure effective sealing. |

These specifications provide a comprehensive overview of the 20″ Pipe Flange, including its size, pressure rating, material, flange type, surface finish, and gasket compatibility. If you require more information or a quotation, please feel free to contact our team, and we will provide personalized assistance and support.

A. Size and Dimensions

The 20″ Pipe Flange by YANHAO is meticulously engineered to meet precise size and dimension requirements:

- Nominal Diameter: The flange features a nominal diameter of 20 inches (508 mm), ensuring compatibility with pipes of the same size.

- Flange Thickness: Our flange has a standardized thickness, guaranteeing a secure and leak-free connection.

- Bolt Hole Diameter: The bolt hole diameter is designed to accommodate the appropriate size of bolts for a firm and safe attachment.

- Facing: The flange face is machined to specific smoothness and flatness standards, facilitating a proper seal with gaskets.

B. Material Composition

The material composition of our 20″ Pipe Flange is chosen with utmost care to provide exceptional durability and resistance:

- Material: Typically, our flanges are crafted from high-quality materials such as carbon steel, stainless steel, or alloy steel, chosen based on the application’s demands.

- Corrosion Resistance: The materials used are resistant to corrosion, ensuring a long service life, even in aggressive environments.

- Heat Resistance: Depending on the material, our flanges exhibit excellent heat resistance properties, making them suitable for high-temperature applications.

C. Pressure Ratings

Our 20″ Pipe Flange is designed to handle a wide range of pressure levels, ensuring versatility and safety:

- Pressure Class: We offer flanges designed for different pressure classes, such as 150, 300, 600, and 900 pounds per square inch (PSI). This range allows for flexibility in selecting the appropriate flange for your specific pressure requirements.

- Temperature Range: These flanges are engineered to operate within specified temperature limits, ensuring consistent performance under varying conditions.

D. Flange Types

YANHAO offers a variety of flange types to cater to diverse industrial applications:

- Weld Neck Flange: This type is designed for high-pressure, high-temperature applications. It features a neck that is welded to the pipe, providing excellent strength and durability.

- Slip-On Flange: These flanges are easy to install and are suitable for low-pressure systems. They slide over the pipe and are secured in place with welding or bolting.

- Blind Flange: Used to close the end of a piping system, blind flanges do not have a bore. They are commonly used in applications where future expansion or maintenance may be required.

- And More: Depending on your project requirements, we offer other types such as socket weld, threaded, lap joint, and more.

E. Standards and Certifications

Our 20″ Pipe Flange adheres to rigorous industry standards and holds essential certifications:

- ANSI/ASME Standards: These flanges comply with ANSI/ASME B16.5, B16.47, and other relevant standards, ensuring compatibility and reliability in various industries.

- API Certifications: Depending on the application, our flanges may carry API certifications, particularly in industries like oil and gas.

- Third-Party Verification: Our products are often subjected to third-party inspections and quality verifications, guaranteeing their performance and safety.

These comprehensive product specifications make YANHAO’s 20″ Pipe Flange the top choice for industries seeking precision, durability, and performance excellence.

II. Applications

A. Industrial Sectors

Our 20″ Pipe Flange finds extensive utility across a broad spectrum of industrial sectors, including but not limited to:

- Oil and Gas: In upstream, midstream, and downstream operations, our flanges play a pivotal role in the transportation and processing of oil and gas resources.

- Petrochemical Industry: For the handling and refining of various petrochemical products, our flanges ensure secure connections within complex piping systems.

- Chemical Manufacturing: Flawless chemical processes demand the reliability and corrosion resistance that our flanges offer.

- Power Generation: Whether in conventional or renewable energy, our flanges are instrumental in the distribution and management of power resources.

- Water Treatment: The water treatment sector relies on our flanges for efficient conveyance and treatment of water and wastewater.

- Mining and Minerals: From ore processing to material handling, our flanges contribute to the efficiency and safety of mining operations.

- Construction and Infrastructure: In building HVAC systems, water supply networks, and more, our flanges ensure dependable performance.

- Marine and Shipbuilding: Marine applications require the durability and corrosion resistance offered by our flanges for seawater environments.

- Agriculture: In irrigation systems and agricultural machinery, our flanges provide reliable fluid control.

B. Use Cases

Explore real-world use cases where our 20″ Pipe Flange excels:

- Pipeline Systems: Vital for connecting segments of pipelines in oil, gas, and water distribution networks.

- Pressure Vessels: Ensuring safe and reliable connections in pressure vessel applications.

- Chemical Reactors: Facilitating the secure flow of chemicals within reactors.

- Storage Tanks: Used for attaching inlet and outlet pipes on storage tanks for various liquids and gases.

- Heat Exchangers: Enabling efficient heat transfer in industrial processes.

- Hydraulic Systems: Essential for hydraulic equipment, ensuring leak-free operation.

- Pump Stations: Reliable connections in pump systems for water and wastewater management.

C. Compatibility with Various Pipe Materials

Our 20″ Pipe Flange exhibits remarkable adaptability, compatible with a wide range of pipe materials, including:

- Carbon Steel Pipes: Ideal for heavy-duty industrial applications.

- Stainless Steel Pipes: Suitable for corrosive and high-temperature environments.

- Alloy Steel Pipes: Offering enhanced strength and heat resistance.

- Plastic Pipes: Facilitating connections in certain chemical and water applications.

D. Environmental Considerations

We understand the importance of environmental responsibility. YANHAO (盐浩公司) is committed to:

- Material Sustainability: Choosing materials that minimize environmental impact while maintaining quality.

- Energy Efficiency: In our manufacturing processes to reduce our carbon footprint.

- Recycling: Implementing recycling practices for waste reduction.

- Compliance: Adhering to environmental regulations and standards in our operations.

Our 20″ Pipe Flange’s versatility, compatibility, and commitment to sustainability make it an invaluable asset across a multitude of industries and applications.

III. Advantages of YANHAO’s 20″ Pipe Flange

A. Quality Assurance

YANHAO places a paramount emphasis on quality assurance throughout the manufacturing process of our 20″ Pipe Flange:

- Stringent Testing: Each flange undergoes rigorous testing protocols, including pressure tests, material analysis, and dimensional checks, ensuring compliance with the highest industry standards.

- Quality Control: Our experienced quality control team meticulously inspects every flange, guaranteeing that it meets our exacting quality benchmarks.

- Traceability: We maintain comprehensive records of materials and manufacturing processes, enabling traceability for every flange produced.

B. Durability and Longevity

The durability and longevity of our 20″ Pipe Flange are second to none:

- Corrosion Resistance: Crafted from materials engineered to withstand corrosion, our flanges have a longer service life even in corrosive environments.

- Robust Construction: Built to withstand high pressures and extreme temperatures, our flanges ensure uninterrupted operation over extended periods.

- Low Maintenance: Reduced maintenance requirements mean less downtime and cost savings over the life of the product.

C. Precision Engineering

Our flanges are the result of precision engineering at its best:

- Exact Fit: The precise dimensions and tolerances of our flanges ensure a perfect fit, reducing the risk of leaks and operational issues.

- Smooth Finish: Meticulously machined flange faces provide a smooth surface for gasket sealing, further enhancing performance.

- Compliance: Our flanges adhere to industry-specific standards, guaranteeing compatibility with a wide range of systems and components.

D. Cost-Efficiency

YANHAO’s 20″ Pipe Flange offers remarkable cost-efficiency over its lifespan:

- Reduced Downtime: Minimized maintenance requirements and fewer replacements mean less downtime for your operations.

- Long-Term Savings: The extended service life of our flanges translates into substantial long-term cost savings.

- Improved Performance: Enhanced efficiency and reliability result in improved overall system performance, optimizing your operational costs.

In choosing YANHAO’s 20″ Pipe Flange, you’re investing in a product that not only meets but exceeds your expectations in quality, durability, precision, and cost-efficiency, ensuring your industrial processes run seamlessly and efficiently.

IV. Technical Expertise

A. Manufacturing Process

Explore the advanced manufacturing process behind our 20″ Pipe Flange:

- Material Selection: Careful selection of high-quality materials, such as carbon steel, stainless steel, or alloy steel, tailored to the application’s demands.

- Forging: Flanges are forged with precision to achieve the desired strength and durability.

- Machining: Meticulous machining of flange faces and bolt holes ensures exact dimensions and a smooth surface finish.

- Heat Treatment: Controlled heat treatment processes enhance the flange’s mechanical properties and resistance to deformation.

B. Quality Control Measures

YANHAO upholds the highest quality standards at every stage of production:

- In-Process Inspection: Our dedicated quality control team performs ongoing inspections during manufacturing to identify and rectify any deviations from specifications.

- Material Verification: Comprehensive material analysis ensures that the selected materials meet required specifications.

- Dimensional Checks: Precise measurements and dimensional checks confirm that every flange meets exacting tolerances.

C. Testing and Inspection Procedures

Rigorous testing and inspection procedures guarantee the reliability of our 20″ Pipe Flange:

- Pressure Testing: Flanges undergo hydrostatic and pneumatic pressure tests to ensure they can withstand the specified pressures safely.

- Non-Destructive Testing: Ultrasonic and radiographic tests are conducted to detect any internal defects or irregularities.

- Visual Inspection: Flanges are visually inspected for surface finish, weld quality, and adherence to standards.

D. Compliance with Industry Standards

Our commitment to industry standards and certifications is unwavering:

- ANSI/ASME Standards: Our flanges conform to ANSI/ASME B16.5, B16.47, and other relevant standards, ensuring compatibility and reliability.

- API Certifications: In industries like oil and gas, our flanges often carry API certifications, signifying their suitability for critical applications.

- Third-Party Verification: Many of our products are subjected to third-party inspections and quality verifications, providing an extra layer of assurance.

With YANHAO’s technical expertise, you can trust that our 20″ Pipe Flange is engineered and manufactured to the highest industry standards, ensuring performance, reliability, and safety in your operations.

V. Why Choose YANHAO

A. Company Reputation

- Proven Track Record: YANHAO has built a solid reputation over the years, becoming a trusted name in the industry. Our consistent delivery of high-quality products and unwavering commitment to excellence has earned us the respect of customers worldwide.

- Reliability: Our reputation is grounded in the reliability of our products and services. Countless satisfied customers rely on us for their critical industrial needs.

B. Customer Testimonials

- Real-World Feedback: Don’t just take our word for it. Hear from our customers through their testimonials. Discover how our 20″ Pipe Flange has made a difference in their operations, offering reliability, efficiency, and cost savings.

- Case Studies: Explore real-world case studies that showcase the successful implementation of our flanges in diverse industries and applications.

C. Commitment to Sustainability

- Environmental Responsibility: YANHAO is committed to sustainability. We prioritize eco-friendly practices in our manufacturing processes, ensuring minimal environmental impact.

- Quality and Sustainability: Our dedication to quality extends to sustainability. We believe that quality products should also be responsible products, contributing to a greener future.

D. Global Reach and Customer Support

- Global Presence: With a worldwide presence, YANHAO is equipped to serve customers on a global scale. No matter where your operations are located, we can provide the flange solutions you need.

- Dedicated Customer Support: Our customer support team is always ready to assist you. Whether you have questions, need technical guidance, or require post-purchase support, we’re here to ensure your satisfaction.

Choosing YANHAO means choosing a company with a proven reputation for quality and reliability. Our commitment to sustainability aligns with modern environmental standards, and our global presence ensures that you have a partner you can rely on, no matter where your business takes you.

VI. Ordering and Availability

A. Ordering Process

- Streamlined Ordering: Our ordering process is designed for efficiency and ease. Whether you’re a returning customer or new to YANHAO, you’ll find the process straightforward.

- Dedicated Sales Team: Our knowledgeable sales team is ready to assist you at every step, ensuring you get the right flange solution for your specific requirements.

- Online Ordering: For your convenience, we offer online ordering options, allowing you to place orders at any time, 24/7.

B. Lead Times and Delivery Options

- Prompt Delivery: We understand the importance of timely delivery in your operations. Our commitment to efficiency means that we strive to meet your delivery timelines.

- Flexible Delivery Options: Choose from a range of delivery options that suit your needs. Whether you require standard shipping or expedited delivery, we can accommodate your preferences.

- International Shipping: Our global reach extends to international shipping, ensuring that our products are available wherever your projects take you.

C. Stock Availability

- Ready-to-Ship Inventory: YANHAO maintains a substantial inventory of 20″ Pipe Flanges, ensuring that standard products are readily available for immediate shipment.

- Dependable Supply: We have established robust supply chain networks to maintain consistent stock levels, reducing the risk of product shortages.

D. Customization Options

- Tailored Solutions: If your project demands unique specifications, we offer customization options. Discuss your requirements with our team, and we’ll work to provide a flange solution that meets your precise needs.

- Materials and Dimensions: Customize the material composition, dimensions, and other parameters to ensure the flange aligns perfectly with your project requirements.

- Coating and Finish: Choose from various coating and finish options to enhance corrosion resistance and performance in specific environments.

Our commitment to a seamless ordering experience, timely delivery, and flexible customization options ensures that you have access to the 20″ Pipe Flange solution that precisely matches your project requirements, backed by the reliability of YANHAO.

VII. FAQs

Q1: What is a 20″ Pipe Flange, and what is its purpose?

A: A 20″ Pipe Flange is a crucial component used to connect two pipes in various industrial applications. Its primary purpose is to provide a secure and leak-free connection while allowing for easy assembly and disassembly of piping systems.

Q2: What materials are available for the 20″ Pipe Flange, and how do I choose the right one for my application?

A: We offer our 20″ Pipe Flange in various materials, including carbon steel, stainless steel, and alloy steel. The choice of material depends on factors like the type of fluid, temperature, and environmental conditions. Our experts can help you select the most suitable material for your specific needs.

Q3: What types of 20″ Pipe Flanges are available, and how do I know which one to use?

A: We offer different types of flanges, including Weld Neck, Slip-On, Blind, and more. The selection depends on factors like the application, pressure, and temperature requirements. Our technical documentation and customer support team can assist you in choosing the right type for your project.

Q4: Can I get customized 20″ Pipe Flanges to meet my unique requirements?

A: Yes, we offer customization options for our flanges. You can specify dimensions, materials, coatings, and other parameters to tailor the flange to your exact needs. Contact our team to discuss your customization requirements.

Q5: How do I ensure a proper fit and seal with the 20″ Pipe Flange?

A: Achieving a proper fit and seal is essential. Follow the installation guidelines provided in our technical documentation, which include proper torque values for bolting and gasket selection. Ensuring that flange faces are smooth and free from imperfections is crucial for a reliable seal.

Q6: Are YANHAO’s (盐浩公司) 20″ Pipe Flanges compliant with industry standards and certifications?

A: Yes, our flanges are designed and manufactured to meet industry standards, such as ANSI/ASME B16.5 and B16.47. They often carry relevant certifications, ensuring they meet the safety and performance requirements for various applications.

Q7: What is the typical lead time for ordering 20″ Pipe Flanges, and what are the delivery options?

A: Lead times can vary based on factors like product availability and customization requirements. We offer flexible delivery options, including standard and expedited shipping, to meet your project’s timelines. Contact our sales team for specific lead time estimates.

Q8: How can I access technical documentation, product datasheets, and catalogs for the 20″ Pipe Flange?

A: You can easily access technical resources and documentation on our website. Download product datasheets, catalogs, and technical guides for detailed information on our 20″ Pipe Flange.

VIII. Contact Information

For inquiries, assistance, or to request a quote for our 20″ Pipe Flange, please reach out to us using the following contact details:

- Phone: +86 13313073735

- Email: flanges.yh@gmail.com

- Address: Xiaozhuangzi Road Section, Xinda Highway, Mengcun Hui Autonomous County, Cangzhou City, Hebei Province

Our dedicated team is ready to assist you with any questions you may have or to provide you with a customized quote tailored to your specific requirements.

Ready to experience the precision, durability, and performance excellence of YANHAO’s (盐浩公司) 20″ Pipe Flange? Contact us today for a quote and discover how our flange solution can optimize your industrial operations.

Don’t miss the opportunity to enhance the reliability and efficiency of your piping systems. Reach out to us now, and let’s start working together to meet your industrial needs.