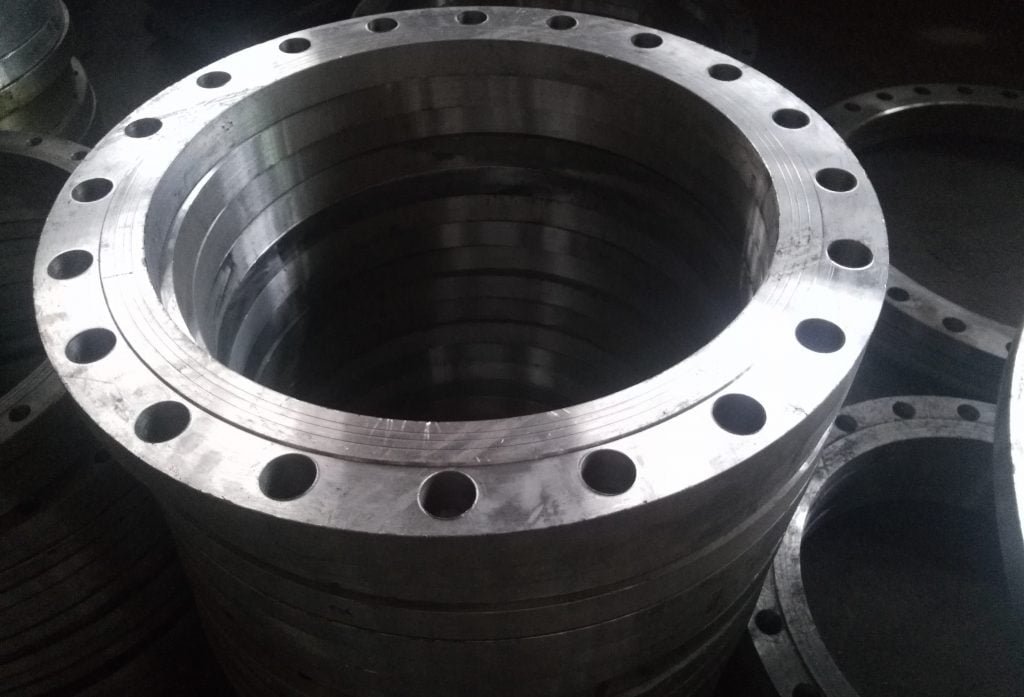

14″ pipe flange

Welcome to YANHAO Company’s comprehensive guide on 14″ pipe flanges. As experts in the field, we provide you with a detailed and authoritative resource to help you understand, select, and use 14″ pipe flanges for your industrial needs.

1. Overview of 14″ Pipe Flanges

Here are the detailed specifications for the 14″ Pipe Flange:

| Specification | Detailed Description |

|---|---|

| Size | 14 inches (Inches) |

| Pressure Rating | ANSI 150, ANSI 300, ANSI 600, ANSI 900, ANSI 1500, ANSI 2500 |

| Material | Stainless Steel, Carbon Steel, Alloy Steel, or other specialized alloy materials (per customer requirements) |

| Flange Type | Weld Neck, Slip-On, Blind, Threaded, Forged, Lap Joint, Threaded Neck, Socket Weld, Flat Face, or other specialized types (per customer requirements) |

| Surface Finish | Smooth, Raised Face, Concave Face, Oval, or other specialized surface finishes (per customer requirements) |

| Gasket Compatibility | Designed for compatibility with various gasket materials, including rubber, metal, graphite, and others, to ensure effective sealing. |

These specifications provide a comprehensive overview of the 14″ Pipe Flange, including its size, pressure rating, material, flange type, surface finish, and gasket compatibility. If you require more information or a quotation, please feel free to contact our team, and we will provide personalized assistance and support.

1.1 Definition and Purpose

At YANHAO, we understand that 14″ pipe flanges are essential components in various industrial applications. These flanges serve as connectors, allowing for the secure and leak-free connection of pipes, valves, and equipment. They play a pivotal role in ensuring the smooth and efficient operation of fluid systems.

1.2 Common Materials and Standards

When it comes to 14″ pipe flanges, YANHAO prioritizes the use of high-quality materials. We offer flanges made from various materials, including carbon steel, stainless steel, and alloy steel. Each material is carefully selected to align with the specific demands of your application. Our flanges adhere to industry standards such as ANSI/ASME B16.5, ensuring compatibility and reliability.

1.3 Industry Applications

YANHAO’s 14″ pipe flanges find widespread use across various industries. In the oil and gas sector, they withstand the rigorous demands of high-pressure pipelines. In chemical processing, our flanges resist corrosive chemicals, maintaining system integrity. Power generation relies on them for efficient energy production, while water and wastewater treatment facilities trust our flanges for reliable water management. These flanges also have applications in construction, marine, food and beverage, and more.

2. Types of 14″ Pipe Flanges

2.1 Weld Neck Flange

YANHAO’s weld neck flanges feature a tapered hub that ensures a robust structural connection. They are meticulously welded to the pipe, guaranteeing a reliable and durable joint. These flanges are a preferred choice for high-pressure and high-temperature applications, where safety and performance are paramount.

2.2 Slip-On Flange

Our slip-on flanges are designed with a flat face and a slightly larger bore, allowing them to slip effortlessly over the pipe and then be welded securely in place. These flanges are ideal for low-pressure applications, offering ease of assembly and disassembly, making maintenance hassle-free.

2.3 Blind Flange

YANHAO’s blind flanges serve as solid disks with no bore, effectively sealing off the end of pipes, vessels, or valves. These flanges are crucial for pressure testing systems and instances where the isolation of a pipeline section is necessary for maintenance or safety.

2.4 Lap Joint Flange

Our lap joint flanges consist of two components: a stub end and a backing flange. The stub end is welded to the pipe, while the backing flange can rotate freely. This design is perfect for systems that require frequent dismantling and realignment, ensuring efficiency and adaptability.

2.5 Socket Weld Flange

YANHAO’s socket weld flanges incorporate a recessed area where the pipe is inserted and then fillet-welded around the perimeter. These flanges offer a smooth bore and exceptional structural integrity, making them suitable for small-bore, high-pressure pipelines.

2.6 Threaded Flange

Threaded flanges feature threads on their inner bore, allowing them to be conveniently screwed onto the pipe. YANHAO recommends these flanges for plumbing systems, small-diameter pipelines, and applications where ease of disassembly is critical.

Each type of 14″ pipe flange from YANHAO is meticulously crafted to meet the unique demands of various applications, delivering on our promise of reliability and performance.

3. Key Considerations for 14″ Pipe Flange Selection

3.1 Material Selection

At YANHAO, we recognize that material selection is a critical factor in ensuring the longevity and performance of 14″ pipe flanges. We offer a range of materials, each carefully chosen to suit specific applications. Carbon steel provides strength and durability, while stainless steel offers corrosion resistance. Alloy steel is an excellent choice for applications with high-temperature and pressure requirements. We also have expertise in handling exotic materials like titanium and Hastelloy for specialized needs.

3.2 Pressure and Temperature Ratings

Choosing the right pressure and temperature ratings for your 14″ pipe flanges is essential to prevent leaks and system failures. YANHAO provides detailed guidance on determining the required ratings based on your system’s working conditions. Our expert recommendations ensure that the selected flanges can withstand the specified pressure and temperature ranges, ensuring safety and reliability.

3.3 Flange Face Finish

Flange face finish plays a pivotal role in achieving a secure seal and preventing leaks. YANHAO offers various flange face finishes, including raised face, flat face, and ring-type joint facing. We guide you in selecting the most suitable finish for your application to ensure a perfect fit and leak-free connection.

3.4 Bolt Hole Patterns

The bolt hole pattern of your 14″ pipe flanges is crucial for proper alignment and assembly. YANHAO adheres to standard bolt hole patterns such as ANSI/ASME B16.5, API, and DIN, ensuring compatibility with industry norms. However, we also understand that unique projects may require custom bolt hole patterns, and we have the capability to accommodate such specific needs while maintaining structural integrity.

3.5 Gasket Selection

Gaskets are an integral part of ensuring a leak-free connection with 14″ pipe flanges. YANHAO provides guidance on selecting the right gasket material, taking into account factors such as fluid compatibility, temperature, and pressure. We offer a variety of gasket types, including full-face gaskets and ring gaskets, to suit different applications and sealing requirements.

At YANHAO, we are dedicated to helping you make informed decisions during the selection process, ensuring that your 14″ pipe flanges meet the highest standards of performance, safety, and reliability.

4. Installation and Maintenance

4.1 Installation Guidelines

At YANHAO, we understand that proper installation is crucial for the long-term performance of 14″ pipe flanges. Our installation guidelines are designed to ensure a secure and leak-free connection:

- Pre-Installation Inspection: We recommend a thorough inspection of flanges, gaskets, bolts, and pipes before installation to verify their condition and compliance with specifications.

- Alignment and Positioning: Proper alignment and positioning of flanges are emphasized to prevent undue stress on the assembly and ensure a leak-tight connection.

- Torque Specifications: YANHAO provides precise torque specifications for tightening flange bolts. We stress the importance of using calibrated torque wrenches to achieve uniform bolt tension.

- Bolt Lubrication: Proper lubrication of bolt threads and nuts is crucial, and we guide you on the appropriate lubrication techniques.

- Flange Assembly: We offer step-by-step instructions for assembling and aligning flanges correctly to guarantee a reliable joint.

4.2 Proper Tightening Techniques

YANHAO places great importance on the proper tightening of flange bolts to prevent leaks and ensure the structural integrity of the connection:

- Bolt Tightening Sequence: We emphasize the use of specific bolt tightening sequences, such as a cross-pattern, to evenly distribute loads and reduce the risk of gasket damage.

- Torque vs. Tension: We explain the differences between torque-based and tension-based tightening methods and provide guidance on when each approach is appropriate.

- Use of Gaskets: Our guidelines stress the significance of gaskets in achieving a proper seal, including their role in bolt tightening procedures.

- Tightening Tools: We recommend the use of calibrated torque wrenches and hydraulic tensioners to achieve accurate and uniform bolt tightening.

4.3 Routine Maintenance

Maintaining the integrity of your 14″ pipe flanges is essential for long-term performance. YANHAO provides detailed guidance on routine maintenance:

- Inspection Schedule: We assist you in establishing a regular inspection schedule to identify and address issues promptly.

- Visual Inspections: Our guidelines cover what to look for during visual inspections, including signs of leaks, corrosion, and gasket wear.

- Tightening Checks: We recommend periodic re-tightening of flange bolts to account for factors like settlement and temperature changes.

- Gasket Replacement: YANHAO details the conditions under which gaskets should be replaced and provides step-by-step instructions for gasket replacement.

- Corrosion Protection: We discuss measures to protect flanges from corrosion, including coatings and cathodic protection.

4.4 Troubleshooting and Repairs

YANHAO recognizes that issues can arise with 14″ pipe flanges, and we offer guidance on troubleshooting and repairs:

- Common Issues: We list common problems that can occur with flange connections, such as leaks, bolt loosening, and gasket failure.

- Troubleshooting Steps: Our guidelines provide a systematic approach for identifying and addressing issues with flange connections.

- Emergency Repairs: YANHAO offers advice on emergency repair procedures to mitigate leaks and maintain safety in critical situations.

Our comprehensive installation and maintenance instructions ensure that your 14″ pipe flanges continue to perform reliably and meet safety standards throughout their operational life.

5. YANHAO’s 14″ Pipe Flanges

5.1 Quality Assurance

At YANHAO, our commitment to quality is unwavering. We take pride in delivering 14″ pipe flanges that meet and exceed industry standards. Here’s what sets us apart:

- Manufacturing Standards: Our flanges are manufactured to the highest industry standards, ensuring consistency and reliability in every product.

- Quality Control Processes: YANHAO’s stringent quality control processes involve rigorous material testing, dimensional checks, and comprehensive inspections at every stage of manufacturing.

- Traceability: We prioritize traceability, allowing us to provide complete transparency about the materials and manufacturing processes used in the production of your flanges.

5.2 Customization Options

We understand that every project is unique, and off-the-shelf solutions may not always suffice. That’s why we offer a range of customization options to tailor 14″ pipe flanges to your specific needs:

- Tailored Solutions: YANHAO specializes in providing customized flanges that precisely match your project requirements.

- Materials and Coatings: Choose from a wide range of materials and coatings to ensure compatibility with your application’s demands.

- Flange Types and Dimensions: We offer flexibility in terms of flange types, dimensions, and drilling standards, allowing you to select the perfect fit.

- Special Requirements: YANHAO has the expertise and capability to accommodate special requirements, such as unique bolt hole patterns or exotic materials, to ensure your project’s success.

5.3 Competitive Pricing

Affordability without compromising quality is a core principle at YANHAO. We offer competitive pricing for our 14″ pipe flanges while delivering outstanding value:

- Affordability: YANHAO’s commitment to competitive and cost-effective pricing ensures that you get high-quality flanges without breaking your budget.

- Bulk and Project Pricing: We offer pricing advantages for bulk orders and large-scale projects, making it economically feasible for various industries.

- Value Proposition: Our approach balances quality, customization, and affordability, providing a compelling value proposition for our customers.

- Request a Quote: We encourage you to request a customized quote based on your specific project needs. Our transparent pricing ensures you have clarity and confidence in your investment.

When you choose YANHAO for your 14″ pipe flanges, you can expect exceptional quality, customization options to match your unique requirements, and competitive pricing that aligns with your budgetary considerations. We are committed to delivering the best value for your investment.

6. Why Choose YANHAO for 14″ Pipe Flanges

6.1 Expertise and Experience

When you choose YANHAO for your 14″ pipe flange needs, you benefit from our extensive expertise and experience in the industry. Here’s why our experience matters:

- Industry Knowledge: We have a deep understanding of the complexities of pipe flanges and their critical role in various industries. Our knowledge ensures that you receive expert guidance and solutions.

- Skilled Team: YANHAO boasts a team of skilled professionals and engineers who are well-versed in industry standards and best practices. They bring years of hands-on experience to the table, guaranteeing the highest level of expertise.

- Proven Track Record: Our portfolio includes a wide range of successful projects across diverse industries. Our experience speaks for itself, showcasing our ability to tackle complex challenges and deliver reliable solutions.

6.2 Stringent Quality Control

Quality is the cornerstone of everything we do at YANHAO. We prioritize quality control to ensure that our 14″ pipe flanges meet the highest standards:

- Quality Assurance: YANHAO is committed to delivering products that adhere to industry standards and certifications. Our manufacturing processes are designed with quality assurance in mind.

- ISO Certifications: We hold ISO certifications and maintain a robust quality management system to ensure consistency and reliability in every flange we produce.

- Testing and Inspection: Our comprehensive testing and inspection procedures leave no room for compromise. We go the extra mile to validate the quality of our 14″ pipe flanges, ensuring they perform flawlessly in demanding environments.

6.3 Customer Testimonials

Our customers’ satisfaction and feedback are a testament to our commitment to excellence. Here’s what some of our valued clients have to say about their experiences with YANHAO:

- Client Feedback: “YANHAO has been our trusted partner for years. Their 14″ pipe flanges have consistently met our high standards, and their customer service is exceptional.”

- Case Studies: “YANHAO’s flanges played a pivotal role in the success of our recent project. Their attention to detail and quality craftsmanship ensured a trouble-free operation.”

- Reliability and Trust: “We rely on YANHAO for our critical applications. Their expertise, quality control, and on-time delivery have made them our go-to supplier.”

Choosing YANHAO for your 14″ pipe flanges means partnering with a company that combines industry expertise, unwavering commitment to quality, and a track record of satisfied customers. We are dedicated to delivering solutions you can trust and depend on.

7. Contact Us

7.1 Request a Quote

Getting in touch with YANHAO for a quote is a simple and straightforward process:

- Online Inquiry Form: You can use our user-friendly online inquiry form to request a customized quote for 14″ pipe flanges. Fill in the required information, including quantity, specifications, materials, and any specific customization requirements.

- Quote Details: YANHAO’s goal is to provide you with an accurate quote that aligns with your project needs. The more details you provide, the better we can tailor our quote to your requirements.

- Response Time: We understand the importance of timely responses. YANHAO is committed to responding promptly to all quote requests. You can expect to receive the information you need quickly and efficiently.

7.2 Technical Support

Our dedicated technical support team is here to assist you with any technical inquiries or challenges you may encounter:

- Experienced Professionals: YANHAO’s technical team comprises experienced professionals with deep industry knowledge. They are well-equipped to address your technical questions and concerns.

- Contact Channels: We provide multiple contact channels to ensure you can reach us easily. You can get in touch with our technical support team via phone or email.

- Product Information: Whether you need guidance on selecting the right 14″ pipe flanges for your application or have technical questions about our products, our team is ready to provide the information you require.

7.3 Customer Service

YANHAO’s commitment to exceptional customer service extends beyond technical support. Our customer service team is here to assist you throughout your engagement with us:

- Dedicated Customer Service: Our customer service department is staffed by dedicated professionals who are eager to address your queries, concerns, and feedback.

- Communication Channels: We provide multiple contact channels for customer service inquiries, including phone numbers and email addresses.

- Order Tracking: YANHAO offers the convenience of order tracking, allowing you to monitor the progress of your orders and receive updates on delivery status.

- Feedback and Support: We encourage you to share your feedback and suggestions. YANHAO values your input and is committed to continuous improvement to better serve your needs.

Whether you need a quote, technical support, or assistance with any aspect of our products or services, YANHAO’s contact options ensure that you can reach out to us conveniently. We are dedicated to providing responsive communication and exceptional customer care.