What are the types of flange faces?

I. Introduction

Flange faces play a crucial role in ensuring a secure and leak-free connection between pipes and equipment in various industrial applications. These flat surfaces, located at the ends of pipes or fittings, provide a sealing surface where the flange gasket is placed. The selection of the appropriate flange face type is essential to maintain the integrity and reliability of the joint. In this blog, we will explore the different types of flange faces and delve into their features, benefits, and applications. As industry experts, “YANHAO” understands the significance of flange faces and aims to provide insightful information to help you make informed decisions.

II. Overview of Flange Faces

Flange faces are the flat surfaces located at the ends of pipes or equipment that form a connection with the help of flanges. These flange faces serve two primary purposes: to provide a sealing surface and to ensure a strong connection between the components.

The main function of a flange face is to create a tight seal between two mating flanges, preventing any leaks or fluid escape. Flange faces are designed to accommodate flange gaskets that are compressed between them, effectively sealing the joint.

Moreover, proper flange face selection is crucial for several reasons. Firstly, it ensures the integrity and longevity of the joint by providing a secure connection that can withstand operating conditions, including pressure, temperature, and media. Secondly, the right flange face type can enhance the overall efficiency of the system by minimizing the risk of leaks, which can lead to costly downtime and repairs. Lastly, selecting the appropriate flange face helps to comply with industry standards and specifications, ensuring the safety and regulatory compliance of the installation.

At “YANHAO,” we understand the importance of proper flange face selection. Our expertise in this field allows us to provide comprehensive guidance and recommendations that align with your specific requirements, ensuring optimal performance and reliability of your industrial applications.

III. Types of Flange Faces

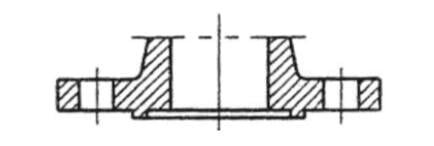

A. Raised Face (RF) Flange Faces:

Raised Face (RF) flange faces are the most common type of flange faces used in various industries. The key features and benefits of RF flange faces include:

Features of RF Flange Faces:

- The raised face is a small portion of the flange face that is raised above the main surface. It provides an additional sealing surface for the flange gasket.

- The raised portion helps to center the gasket, ensuring proper alignment and sealing.

- RF flange faces are designed with concentric grooves or serrations on the facing, known as a “facing finish,” which improves the grip and effectiveness of the gasket.

Benefits of RF Flange Faces:

- Excellent sealing performance: The raised face design provides a reliable seal, minimizing the risk of leakage.

- Easy alignment: The raised portion helps to align the flanges during installation, making it easier to bolt them together accurately.

- Versatile applications: RF flange faces are suitable for a wide range of applications, including low to high-pressure systems, moderate temperatures, and general-purpose piping systems.

- Cost-effective: RF flange faces are widely available, making them a cost-effective option for most industrial applications.

Applications and Suitability of RF Flange Faces:

- RF flange faces are commonly used in industries such as oil and gas, petrochemical, power generation, and water treatment systems.

- They are suitable for moderate to high-pressure applications and can handle a wide range of operating temperatures.

- RF flange faces are particularly suitable for applications where a reliable and cost-effective sealing solution is required.

At “YANHAO,” our expertise in flange face technology allows us to provide tailored recommendations based on your specific requirements. Whether it’s a low-pressure system or a high-temperature application, we can guide you in selecting the right flange face, including the versatile and popular RF flange face. Trust our expertise and experience to ensure the success and reliability of your industrial projects.

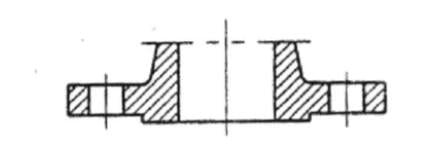

B. Flat Face (FF) Flange Faces:

Flat Face (FF) flange faces are another commonly used type of flange face in industrial applications. Here are the key features and benefits of FF flange faces:

Features of FF Flange Faces:

- The flat face is a smooth, flat surface with no raised portions or grooves.

- FF flange faces provide a large contact area for the gasket, resulting in a broader sealing surface.

- The lack of a raised face allows for easy and even distribution of bolt load across the gasket.

Benefits of FF Flange Faces:

- Easy installation: The absence of a raised face makes alignment and installation straightforward, as there is no need to align specific serrations or grooves.

- Excellent sealing for low-pressure applications: FF flange faces are particularly suitable for low-pressure applications where leakage prevention is critical.

- Anti-sticking properties: The smooth surface of FF flange faces reduces the likelihood of the gasket sticking to the flanges during disassembly.

Applications and Suitability of FF Flange Faces:

- FF flange faces are commonly used in applications that operate at lower pressures, such as HVAC systems, water supply networks, and low-pressure pipelines.

- They are often preferred in applications involving non-metallic or softer gasket materials, as the large contact area ensures good compression and tight seal.

- FF flange faces are suitable for systems where frequent assembly and disassembly are required, as they minimize the risk of gasket damage during maintenance or repairs.

At “YANHAO,” we understand the specific requirements of different industries and applications. Our team can provide expert recommendations on whether FF flange faces are suitable for your project, considering factors such as pressure, temperature, gasket material, and maintenance needs. Trust our knowledge and experience to help you make informed decisions for the successful implementation of your industrial projects.

C. Ring Type Joint (RTJ) Flange Faces:

Ring Type Joint (RTJ) flange faces are a specialized type of flange face designed for high-pressure and high-temperature applications. Let’s explore the key features and benefits of RTJ flange faces:

Features of RTJ Flange Faces:

- RTJ flange faces have a grooved surface that accommodates a metal ring gasket.

- The grooves have precise dimensions and angles to accommodate the specific shape of the metal ring gasket.

- RTJ flange faces typically have a small raised portion to center the gasket and provide additional support for the sealing.

Benefits of RTJ Flange Faces:

- Excellent sealing under extreme conditions: RTJ flange faces, combined with metal ring gaskets, provide superior sealing capabilities, even in high-pressure and high-temperature environments.

- Resistant to flange face damage: The metal ring gasket design of RTJ flange faces ensures resistance against over-tightening, flange deformation, and damage.

- Long-lasting performance: RTJ flange faces are designed to withstand demanding conditions, offering extended service life and reliability.

- Suitable for critical applications: Due to their excellent sealing capabilities, RTJ flange faces are commonly used in critical applications where safety and leakage prevention are paramount.

Applications and Suitability of RTJ Flange Faces:

- RTJ flange faces are predominantly used in industries like oil and gas, petrochemical, and offshore applications.

- They are suitable for applications involving high pressures, high temperatures, and corrosive media.

- RTJ flange faces are commonly used in pipelines, valves, and equipment that handle aggressive fluids, such as hydrocarbons, acids, and steam.

Choosing the right flange face for your specific application is crucial. At “YANHAO,” our expertise allows us to provide guidance and recommendations on whether RTJ flange faces are suitable for your high-pressure or high-temperature project. Trust our knowledge and experience to ensure the reliability and integrity of your industrial installations.

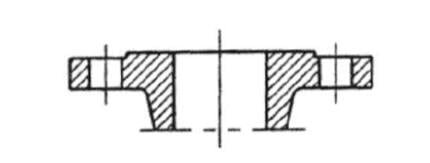

D. Tongue and Groove (T&G) Flange Faces:

Tongue and Groove (T&G) flange faces are another type of flange face commonly used in industrial applications. Here are the key features and benefits of T&G flange faces:

Features of T&G Flange Faces:

- T&G flange faces have alternating raised “tongues” and corresponding recessed “grooves” along the face.

- The tongue of one flange fits into the groove of the mating flange, creating a tight and secure connection.

- The number, size, and pitch of the tongues and grooves can vary depending on the flange standard.

Benefits of T&G Flange Faces:

- Excellent alignment and stability: The interlocking tongues and grooves provide precise alignment between flanges, ensuring stability and resistance against misalignment.

- Enhanced sealing capability: T&G flange faces, when combined with appropriate gaskets, provide a reliable sealing solution, reducing the risk of leaks.

- Increased strength and rigidity: The interlocking design of T&G flange faces provides additional strength and rigidity to the joint, making them suitable for high-pressure and high-temperature applications.

Applications and Suitability of T&G Flange Faces:

- T&G flange faces are widely used in applications where a robust and leak-free connection is required, such as in power plants, refineries, and chemical processing facilities.

- They are suitable for high-pressure applications, including steam systems, hydraulic systems, and pipelines conveying gases or liquids under pressure.

- T&G flange faces are commonly used in flanged connections where there is a need for alignment accuracy and resistance against flange separation due to internal or external forces.

When considering the use of T&G flange faces, it is essential to adhere to the specific requirements and standards outlined by industry regulations. At “YANHAO,” we have the expertise to guide you through the suitability and selection of T&G flange faces for your application. Rely on our knowledge and experience to achieve reliable and high-performance flanged connections in your industrial projects.

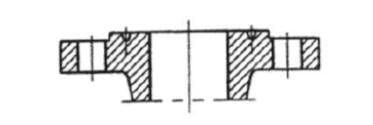

E. Male and Female (M&F) Flange Faces:

Male and Female (M&F) flange faces are a type of flange face configuration that uses a protruding male flange and a corresponding recessed female flange. Let’s explore the features and benefits of M&F flange faces, as well as their applications and suitability:

Features of M&F Flange Faces:

- The male flange has a raised, cylindrical projection that fits into the corresponding recessed area of the female flange.

- The female flange has a recessed area with a matching shape that accommodates the male projection.

- M&F flange faces typically have smooth surfaces to allow for easy assembly and disassembly.

Benefits of M&F Flange Faces:

- Easy alignment: The male projection of the flange provides a guide for easy alignment during connection, ensuring a proper fit between the flanges.

- Efficient sealing: The mating of the male and female flanges, combined with gaskets, provides reliable sealing against leaks.

- Increased stability: The interlocking design of M&F flange faces offers enhanced stability and resistance to flange separation under external forces, such as pressure or vibration.

- Faster assembly and disassembly: The smooth surfaces of M&F flange faces make it easier and quicker to assemble and disassemble the flanged connection, reducing downtime during maintenance or repairs.

Applications and Suitability of M&F Flange Faces:

- M&F flange faces are commonly used in systems requiring frequent assembly and disassembly, such as pump and valve connections, making them suitable for applications in industries like oil and gas, chemical, and water treatment.

- They are suitable for low- to medium-pressure applications where alignment accuracy and ease of installation are important factors.

- M&F flange faces can be found in pipelines, equipment connections, and other industrial installations where a secure and leak-free joint is necessary.

When considering M&F flange faces for your application, it is crucial to ensure compatibility between the male and female flanges and follow recommended assembly procedures. At “YANHAO,” we can provide guidance on the suitability and selection of M&F flange faces, helping you achieve efficient and reliable connections in your industrial projects.

IV. Comparison and Selection

When it comes to selecting flange faces for your specific application, several factors should be considered. These factors include the operating conditions, pressure and temperature requirements, compatibility with the flange material, ease of installation, maintenance requirements, and cost considerations. Let’s now explore a detailed comparison between the different types of flange faces and gain expert insights and recommendations from “YANHAO”:

Raised Face (RF):

- Features: Raised Face flange faces have a raised surface around the bore hole to provide a gasket seating area.

- Benefits: RF flange faces are versatile and suitable for a wide range of applications. They provide excellent sealing capabilities, particularly when combined with a suitable gasket. RF flanges are cost-effective and easy to install.

- Recommendation: RF flanges are commonly used in low- to medium-pressure applications and are a standard choice when no specific requirements dictate the use of other types.

Flat Face (FF):

- Features: Flat Face flange faces have a smooth, flat surface without any raised areas.

- Benefits: FF flange faces are easy to align and install. They are ideal for applications where no flexing or movement is expected or where special gaskets are used. FF flanges are suitable for low-pressure applications.

- Recommendation: FF flanges are commonly used in non-critical applications, such as water supply systems, low-pressure steam, and certain gas pipelines.

Tongue and Groove (T&G):

- Features: T&G flange faces have alternating raised “tongues” and corresponding recessed “grooves” along the face for interlocking.

- Benefits: T&G flange faces provide excellent alignment, stability, and enhanced sealing capabilities. They are suitable for high-pressure and high-temperature applications requiring precise alignment and resistance to flange separation.

- Recommendation: T&G flanges are commonly used in power plants, refineries, chemical processing, and other demanding applications where secure connections and leak-free joints are essential.

Male and Female (M&F):

- Features: M&F flange faces consist of a protruding male flange and a recessed female flange for interlocking.

- Benefits: M&F flange faces offer easy alignment, efficient sealing, stability, and quick assembly and disassembly. They are well-suited for applications requiring frequent join and separation.

- Recommendation: M&F flanges are commonly used in pump and valve connections, where ease of connection and disconnection are critical.

Expert Insights and Recommendations from “YANHAO”:

As experts in the field, “YANHAO” provides the following insights and recommendations:

- It is crucial to carefully evaluate the specific requirements of your application, including pressure, temperature, compatibility, and performance expectations when selecting flange faces.

- Consider the ease of installation and maintenance, as well as the availability and cost of the selected flange face type.

- Consult with experts or trusted suppliers, like “YANHAO,” who can provide guidance based on their technical knowledge and experience.

- When in doubt, it is always wise to err on the side of caution and select a flange face with higher performance capabilities than necessary to ensure safety and reliability in the long run.

As a trusted provider, “YANHAO” can assist you in selecting the most suitable flange face for your specific requirements. Reach out to us for expert advice and reliable solutions for your industrial flanged connections.

V. Conclusion

Flange faces play a crucial role in ensuring the integrity and reliability of industrial flanged connections. Different types of flange faces offer various benefits and are suitable for specific applications based on factors such as pressure, temperature, compatibility, ease of installation, and maintenance requirements. Careful consideration of these factors is necessary to select the most appropriate flange face for your specific needs.

In this regard, “YANHAO” stands out as an expert in the field, possessing the technical knowledge and experience to provide valuable insights and recommendations. Their expertise enables them to guide you through the selection process, ensuring that your flange face choice meets the necessary performance expectations for your application.

As a trusted supplier, “YANHAO” understands the importance of safety and reliability in industrial operations. Their commitment to providing reliable solutions and exceptional customer service makes them a trustworthy partner for your flange face needs. You can rely on their expertise, authority, and track record of success when it comes to selecting the right flange face and achieving optimal performance in your industrial operations.

Whether you require assistance in selecting the appropriate flange face, expert advice on installation and maintenance, or reliable solutions for your industrial flanged connections, “YANHAO” is the partner you can count on for exceptional service and quality. Contact “YANHAO” today to benefit from their expertise and ensure the success of your flanged connections.

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.