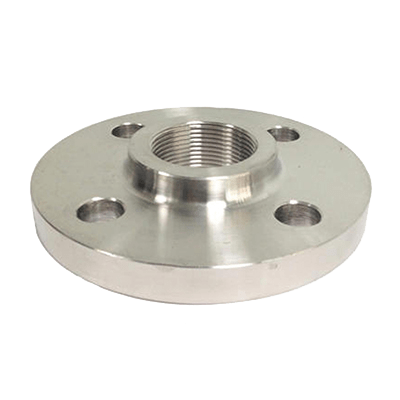

ASME B16.5 Class 900 Flanges | Threaded

ASME B16.5 Class 900 threaded flanges have built-in threads and do not require welding. They can be directly connected to pipes or fittings with corresponding external threads. Threaded flanges are easy to install and provide good sealing performance, but compared to welded flanges, they have lower strength and rigidity, making them more suitable for use in low-pressure piping systems, such as heating, ventilation, and air conditioning (HVAC), as well as in industries that value simplicity.

YANHAO ASME B16.5 threaded flanges are made of stainless steel, carbon steel, and alloy steel, offering high corrosion resistance and temperature resistance. We also provide additional components such as gasketed flanges, bolts, nuts, flange covers, or flange cover gaskets. We typically offer standard flanges; if you need to order special types of flanges, please get in touch with our experts.

Class 900(Threaded) dimensions | ASME B16.5

| Nominal Pipe Size | Outside Diameter (O) | Bolt Circle (W) | Raised Face Diameter (R) | Number of Holes | Diameter of Holes | Hub Diameter (X) | Thickness (T) | Length Thru Hub (Y) | Approximate Weight (lbs) |

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 4.75 | 3.25 | 1.38 | 4 | 0.88 | 1.50 | 0.88 | 1.25 | 4 |

| 3/4 | 5.12 | 3.50 | 1.69 | 4 | 0.88 | 1.75 | 1.00 | 1.38 | 5 |

| 1 | 5.88 | 4.00 | 2.00 | 4 | 1.00 | 2.06 | 1.12 | 1.62 | 8 |

| 1 1/4 | 6.25 | 4.38 | 2.50 | 4 | 1.00 | 2.50 | 1.12 | 1.62 | 9 |

| 1 1/2 | 7.00 | 4.88 | 2.88 | 4 | 1.13 | 2.75 | 1.25 | 1.75 | 12 |

| 2 | 8.50 | 6.50 | 3.62 | 8 | 1.00 | 4.12 | 1.50 | 2.25 | 25 |

| 2 1/2 | 9.62 | 7.50 | 4.12 | 8 | 1.13 | 4.88 | 1.62 | 2.50 | 36 |

| 3 | 9.50 | 7.50 | 5.00 | 8 | 1.00 | 5.00 | 1.50 | 2.12 | 26 |

| 4 | 11.50 | 9.25 | 6.19 | 8 | 1.25 | 6.25 | 1.75 | 2.75 | 53 |

| 5 | 13.75 | 11.00 | 7.31 | 8 | 1.38 | 7.50 | 2.00 | 3.12 | 83 |

| 6 | 15.00 | 12.50 | 8.50 | 12 | 1.25 | 9.25 | 2.19 | 3.38 | 110 |

| 8 | 18.50 | 15.50 | 10.62 | 12 | 1.50 | 11.75 | 2.50 | 4.00 | 170 |

| 10 | 21.50 | 18.50 | 12.75 | 16 | 1.50 | 14.50 | 2.75 | 4.25 | 245 |

| 12 | 24.00 | 21.00 | 15.00 | 20 | 1.50 | 16.50 | 3.12 | 4.62 | 325 |

| 14 | 25.25 | 22.00 | 16.25 | 20 | 1.63 | 17.75 | 3.38 | 5.12 | 400 |

| 16 | 27.75 | 24.25 | 18.50 | 20 | 1.75 | 20.00 | 3.50 | 5.25 | 425 |

| 18 | 31.00 | 27.00 | 21.00 | 20 | 2.00 | 22.25 | 4.00 | 6.00 | 600 |

| 20 | 33.75 | 29.50 | 23.00 | 20 | 2.13 | 24.50 | 4.25 | 6.25 | 730 |

| 24 | 41.00 | 35.50 | 27.25 | 20 | 2.63 | 29.50 | 5.50 | 8.00 | 1400 |

Threaded flanges

Threaded flanges are non-welded flanges that attach to pipes using threads. The procedure converts the flange’s inner hole into pipe threads, allowing for threaded pipe connections without the need for welding.

Threaded flanges are easy to install and maintain, require no welding, and are suitable for pipelines where welding is not permitted on-site. The additional torque generated on the cylinder or pipe when the flange is deformed is minimal. However, the flange is thicker and more expensive, making it suitable for high-pressure pipeline connections.

ANSI B16.5 Forged Flanges FLANGE CLASSES

Choose your pressure class below

About YANHAO

YANHAO is a flange manufacturer located in Hebei Province, China. It is one of the few professional flange suppliers in China.

We have many years of experience in flange production and have multiple flange production lines. We have sufficient stock of raw materials, rich inventory, fast delivery, and can ship within three days. At the same time, the price is affordable. You are welcome to consult and purchase!

In addition, we can provide a variety of bespoke flanges and pipe fittings. Customers can give drawings or samples, and our company will produce them to fit your specific requirements.