Blind Flanges: Types, Uses, and Key Features

In industrial piping systems, blind flanges are indispensable components that act as an end cap to seal pipe openings. Essential in handling hazardous materials, maintaining pressure, or shutting off process lines in industries throughout the world, these disk-shaped components stand.

Blind flanges might look simple, but they are carefully engineered according to exacting safety and performance standards. As the difference between smooth operations and costly failures, their selection and application are important.

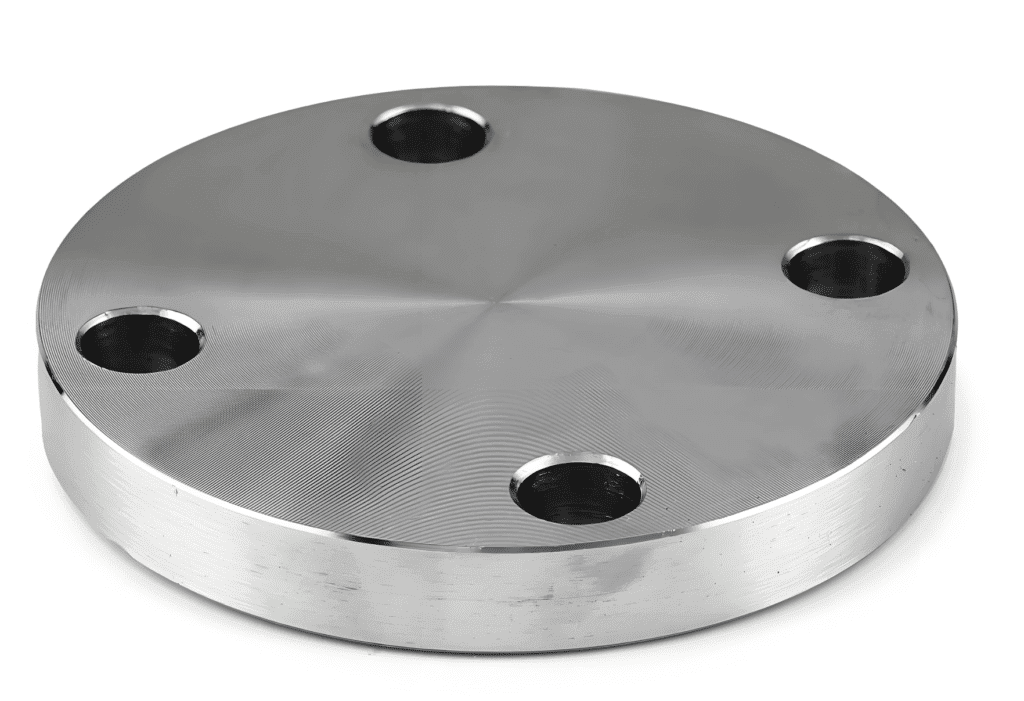

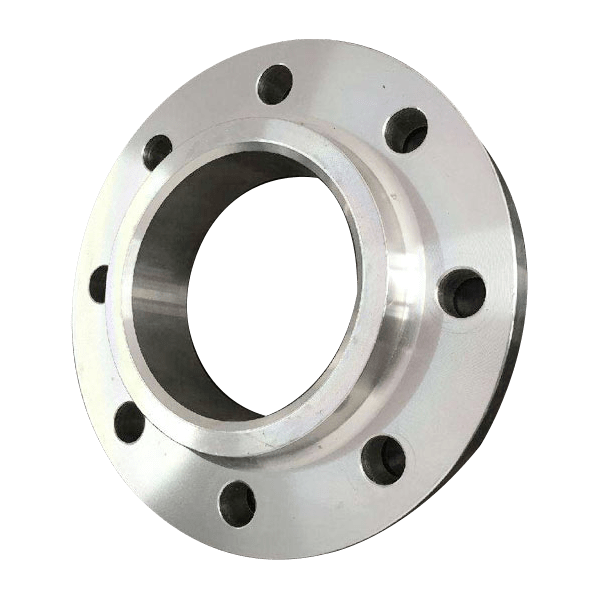

What are Blind flanges?

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints. This is easy to understand: there is no hole in the middle of the cover plate.

A blind flange is a flat circular plate used to close one end of a pipe, valve, or fitting in industrial piping systems. It is predrilled around its circumference with bolt holes that mate to a flange.

Blind flanges are made of different metals, such as carbon steel or stainless steel, and act as a strong, pressure-tight seal to prevent fluid or gas flow and serve as an end cap in piping networks.

Technical Specifications for Blind Flanges

| Technical Parameter | Specifications |

|---|---|

| Size Range | 1/2″ to 60″ (15mm to 1500mm) |

| Pressure Class | ANSI Class 150 to Class 2500 |

| Temperature Range | -196°C to 650°C |

| Material Options | Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel |

| Standards | ASME/ASNI B16.5, ASME/ASNI B16.47, EN 1092-1, BS 4504 |

| Surface Finish | 125-200 AARH32-125 AARH |

| Bolt Hole Pattern | ASME B16.5 standardized |

| Testing Methods | Hydrostatic TestingRadiographic TestingUltrasonic TestingPMI Testing |

| Hardness | Max 200 HB |

Types of Blind Flanges

Flat Face (FF) Blind Flanges

These flanges are completely flat and have a sealing surface across the face.

In simple words: a solid flange with a flat surface.

Used mostly in low-pressure applications up to Class 150, FF blind flanges are common in systems using cast iron and PVC piping.

Their design is simple and especially suited to applications using piping materials that are brittle since they distribute the bolt load and minimize pipe stress. Applications range from water treatment to general process lines operating under 150 psi.

a solid flange with a flat surface.

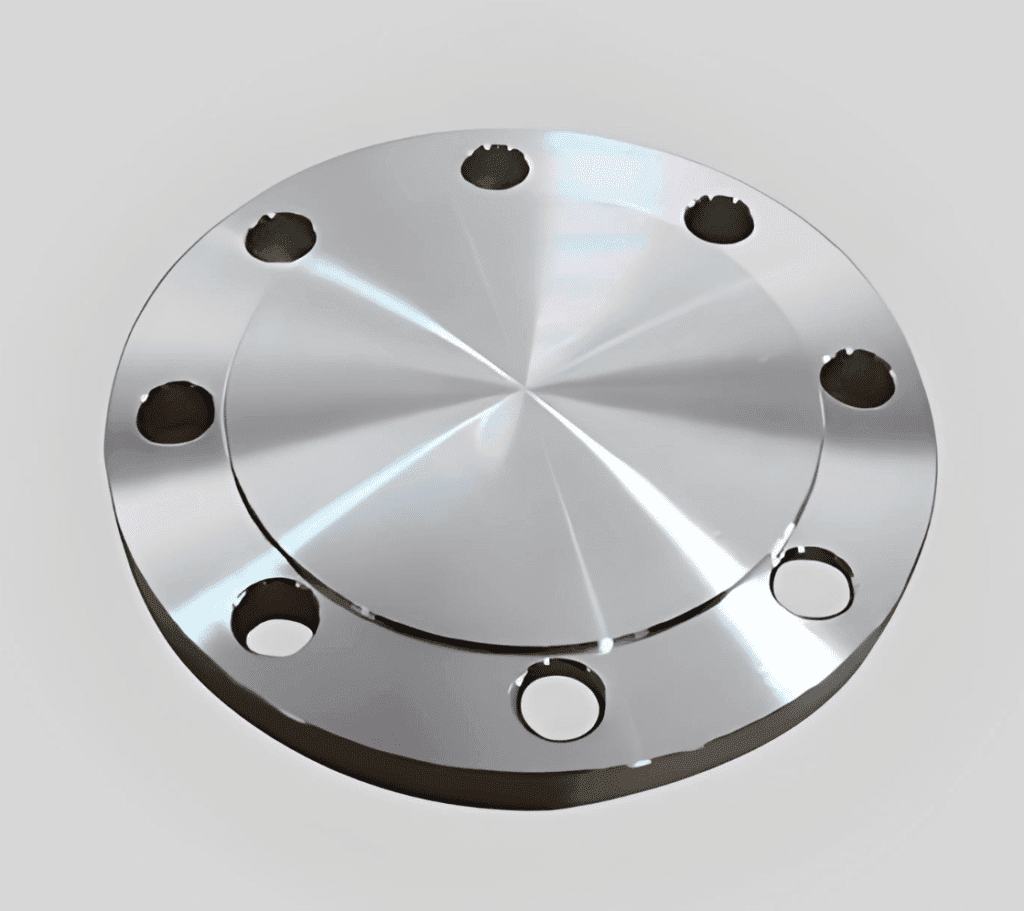

Raised Face (RF) Blind Flanges

Raised face blind flanges (RFBL) are the most common type in the industry. It has an elevated sealing surface that extends slightly above the bolt face. The raised portion is normally 1/16 inch for Class 150/300 and 1/4 inch for Class 400 and above.

a solid flange with a flat surface that extends slightly above the bolt face.

It provides improved sealing by allowing gasket compression to be concentrated. RF flanges handle pressures up to 2500# class and are standard in oil, gas, and chemical processing facilities.

a solid flange with a flat surface that extends slightly above the bolt face.

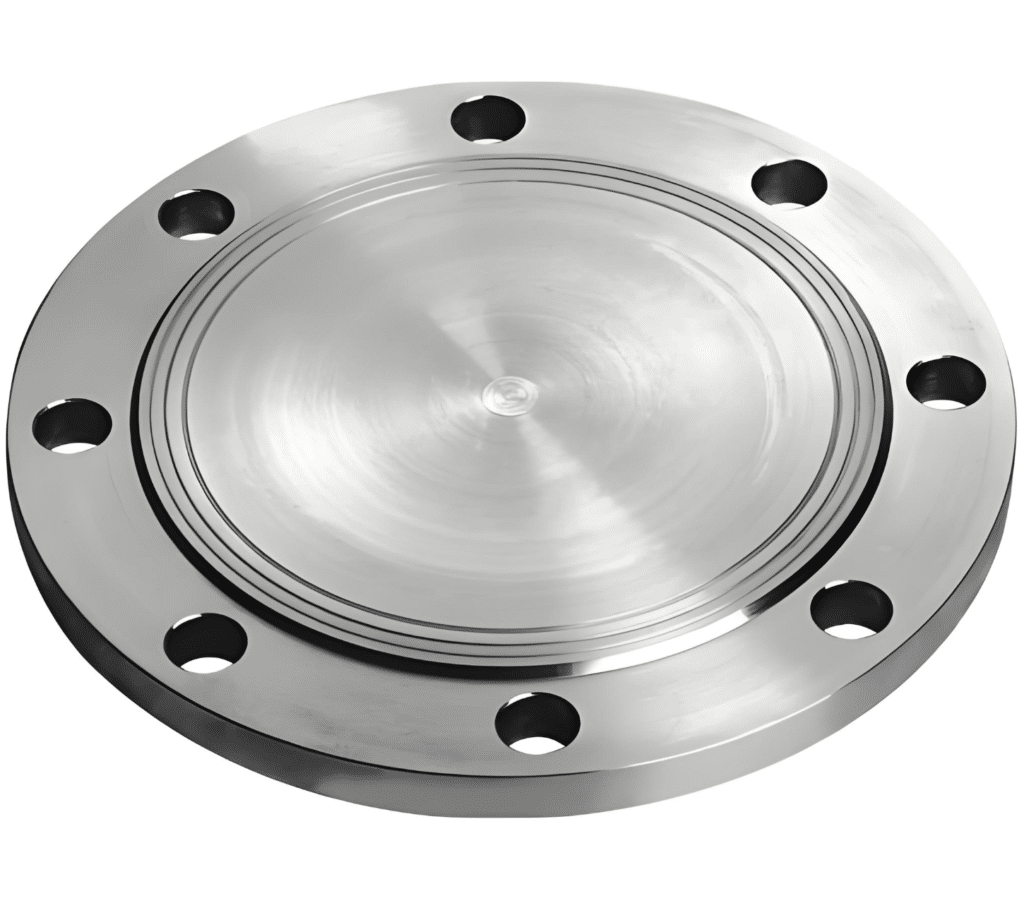

Ring-Type Joint (RTJ) Blind Flanges

RTJ blind flanges are machined with a precise groove on the face to accommodate a metallic ring gasket. The operating pressures and temperatures can be as high as 5000 psi and 1200°F.

Simple words: a blind flange that uses a metal ring to create a seal between two flanges.

A metal-to-metal seal makes it suitable for critical services both in petrochemical plants and offshore platforms. The surface finish in the groove area is carefully controlled at 32 AARH for optimum sealing.

a blind flange that uses a metal ring to create a seal between two flanges.

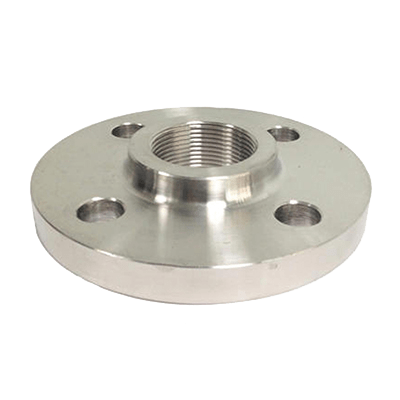

Threaded Blind Flanges

The variety of these flanges includes internal threads, which allow them a direct connection to the threaded pipes without any need to weld or other fittings.

The threaded blind flange is common up to 4 inches for quick installation and removal for temporary closure or test points.

In particular, they are invaluable in maintenance operations and small-diameter utility systems requiring frequent access.

Key Features of Blind Flanges

Blind flanges have many necessary features that make them indispensable in industries. These components are designed with precision, keeping safety and reliability in mind for harsh environments.

Design and Construction

The robust construction and interior of the blind flange eliminate weak points. Each flange is precisely machined to specifications.

Guaranteed perfect fit with connection flange. The thickness has been carefully calculated to meet specific pressure and temperature requirements while maintaining its structural integrity.

Structural Integrity and Strength

Its high tensile power and robust construction make blind flanges able to withstand severe pressure masses.

The strategic thickness distribution ensures even pressure distribution without warping or deformation under pressure.

Key strain factors are bolstered to preserve machine integrity in the course of thermal cycling and pressure fluctuations.

Sealing Capabilities

Engineered sealing faces, whether flat, raised, or RTJ fashion, provide leak-tight connections.

Gasket surfaces are machined to specific roughness values, ensuring the most excellent gasket compression and sealing overall performance.

The layout comprises diverse gasket types, from primary non-metallic to state-of-the-art metal alternatives.

Pressure Resistance Properties

Blind flanges are rated in pressure classes ranging from 150# to 2500#, making them suitable for a range of operating conditions.

In such pressure-bearing capability, the basis is a calculated thickness and selection of materials that have safety factors well above operating requirements.

Material Composition Benefits

From carbon steel to exotic alloys, material selection offers specific advantages:

- Cost-effective strength is offered by carbon steel

- Perfect corrosion resistance is ensured by stainless steel

- Alloy steels provide high-temperature performance

- Corrosion resistance and strength are both combined in duplex grades

Standardized Bolt Patterns

Industry-standard bolt patterns ensure compatibility and proper load distribution. Bolt holes are exactly drilled to hold proper alignment or even gasket compression.

This standardization simplifies setup and renovation approaches across exceptional producers.

Surface Finish Importance

Controlled surface finishes on the sealing faces provide for optimum gasket performance.

Specific roughness values eliminate damage to gaskets while providing seals. Special finishes to provide improved corrosion resistance may be specified or to accommodate specific gasket materials.

Applications of Blind Flanges

Oil and Gas Pipeline Systems

Blind flanges play a crucial role in the pipeline systems of oil and gas by capping off unused branches, isolating sections for maintenance, and creating a secure endpoint in high-pressure lines. On offshore platforms, they seal the pipe ends with crude oil and natural gas at up to 2,500 psi while allowing for easy access for the cleaning of pipelines and inspection.

Chemical Processing Plants

In chemical processes, blind flanges provide safe dead ends in process lines transporting corrosive chemicals, acids, and alkalis. Flanges made of stainless steel and special alloys withstand chemical attack while preserving system integrity. They become indispensable in the isolation of reactor vessels, storage of hazardous materials, and quick process modifications.

Water Treatment Facilities

Blind flanges are used for capping distribution lines at water treatment plants, closing unused ports on storage tanks, and isolation sections for maintenance. They are usually chlorinated water with treatment chemicals, so the materials used have to be duplex stainless steel for longevity. Without them, maintaining pressure in the system and keeping contamination out is impossible.

Power Generation Plants

Power plants utilize blind flanges in steam systems, coolant circuits, and fuel lines. Specialized material handling at high temperatures for up to 1000°F is required. They are especially relevant in boiler systems, where they seal high-pressure steam lines and provide access for periodic boiler maintenance.

Petrochemical Industries

Petrochemical plants have blind flanges throughout their processing systems. From reactor vessel sealing to the isolation of distillation columns, the components have to deal with a variety of hydrocarbons and chemicals. Special considerations include extreme temperature cycling, high pressures, and exposure to aggressive chemicals, often calling for chrome-moly steel or specialized alloys.

YANHAO: Leading Manufacturer of Blind Flanges

YANHAO, as a leading flange manufacturer, has well-deserved fame for its quality and innovative contributions to the flange production industry. It boasts advanced manufacturing with eight pipe fitting and five flange production lines, reaching an annual output of more than 80,000 tons.

The company specializes in a wide range of blind flanges made from carbon steel, stainless steel, and alloy materials for various international standards, such as ASME/ANSI and DIN.

YANHAO ensures strict quality control with comprehensive testing processes, becoming a trusted supplier within industries such as oil and gas, chemical processing, and power generation.

Bottom Line

Blind flanges are critical components within piping systems, providing seals efficiently for different industries. The robustness of their design and the wide range of available materials make them reliable and safe, hence indispensable in view of assuring the efficiency of the fluid transport systems.

The ability to avoid leakages and provide easy access during maintenance makes blind flanges very important in terms of overall industrial integrity.

Other Types of Flanges

Weld Neck Flanges (WN)

WN flange, also known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, the rim, is fitted around the circumference.

China welding neck flange products >>

Slip-on Flanges (SO)

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

China slip-on flange products >>

Socket Weld Flanges (SW)

Socket Weld Flanges (SW) are similar to Slip-on Flanges (SO). The difference is that there is an extra piece in the middle.

China socket weld flange products >>

Blind Flanges (BF)

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints.

China blind flange products >>

Lap joint flange (LJ)

Consisting of two components: a stub end and a lap joint ring flange. The respective stub end is slid into the flange’s bore, and the stub end is joined to the pipe through butt welding.

China lap joint flange products >>

Threaded Flanges (TF)

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe. The installation does not involve welding

China threaded flange products >>

Recommended Readings

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.