Project Case: Custom Flanges, Reducers, Elbows | Iran

Project details

Order Details

Our cooperation with the Iranian client can be traced back to their on-site visit to China in 2024, which laid a strong foundation for mutual trust. The client spent a full week inspecting every aspect of our operations—from raw material storage, including Baogang and Laigang steel, to workshop equipment such as the medium-frequency pushing machine and hot die press, and finally to testing facilities equipped with magnetic particle flaw detectors and hydrostatic testing pumps.

Throughout the process, they raised detailed technical questions, which our engineering team addressed one by one, including how precision was ensured in production and how our testing standards aligned with international norms. At the conclusion of the inspection, the client expressed confidence in our manufacturing capabilities and quality control practices, which set the stage for later cooperation.

When formal discussions began, the client specified the need for a diverse range of pipeline fittings, including flanges, reducers, and elbows, with two critical requirements: all products had to undergo testing by a designated third-party agency, and the packaging needed to be reinforced to withstand long-distance transport to Iran.

We immediately confirmed these requirements and carefully aligned the inspection criteria—covering material composition, pressure resistance, and dimensional tolerances—to ensure full compliance.

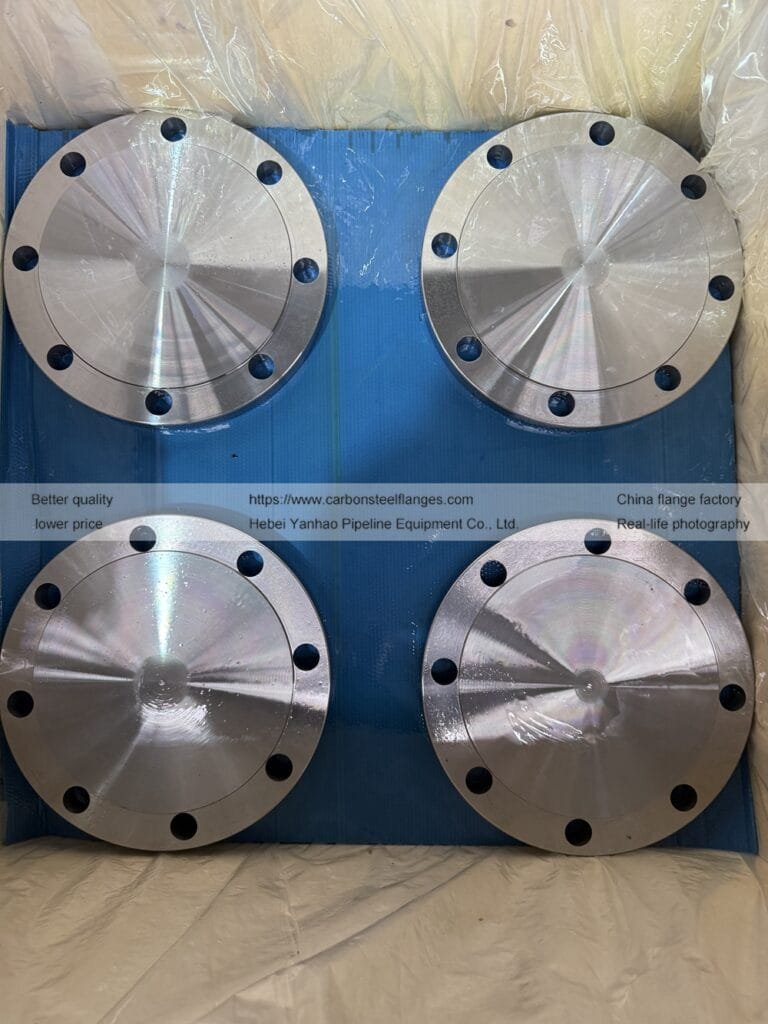

During production, strict precision standards were upheld. Flange sealing surfaces were ground to a smooth, even finish, with bolt-hole positions calibrated by CNC equipment to maintain millimeter-level accuracy. Reducers were manufactured with uniform wall thickness transitions to ensure unobstructed fluid flow, while elbows were formed precisely to the drawings, free from deformation or wrinkling. Quality control was carried out in three stages of internal inspection, followed by independent third-party testing. Certified reports were promptly delivered to the client, who acknowledged their confidence upon review.

Packaging was executed with equal attention to detail. Components were arranged systematically, with protective pads placed between layers to prevent collision and scratching during transport. Each product category was packed into custom-built wooden crates, with foam panels filling the internal gaps to eliminate movement. External markings clearly indicated product type, quantity, handling instructions, and directional signs to ensure safe loading, transport, and delivery.

Customer Testimonials

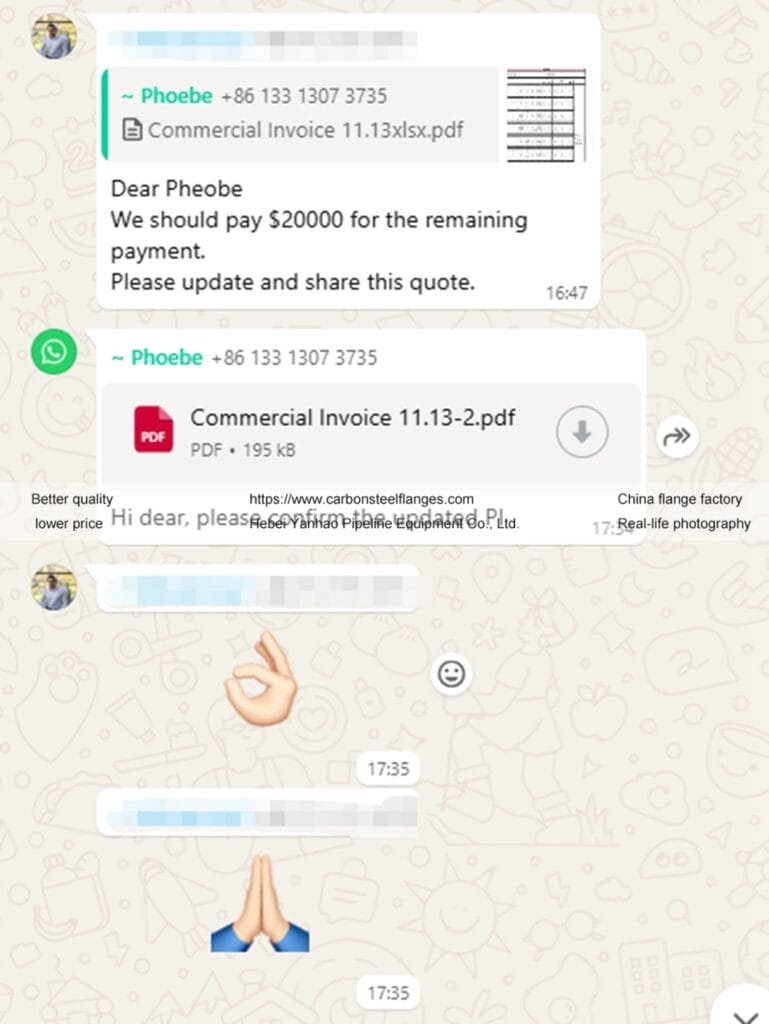

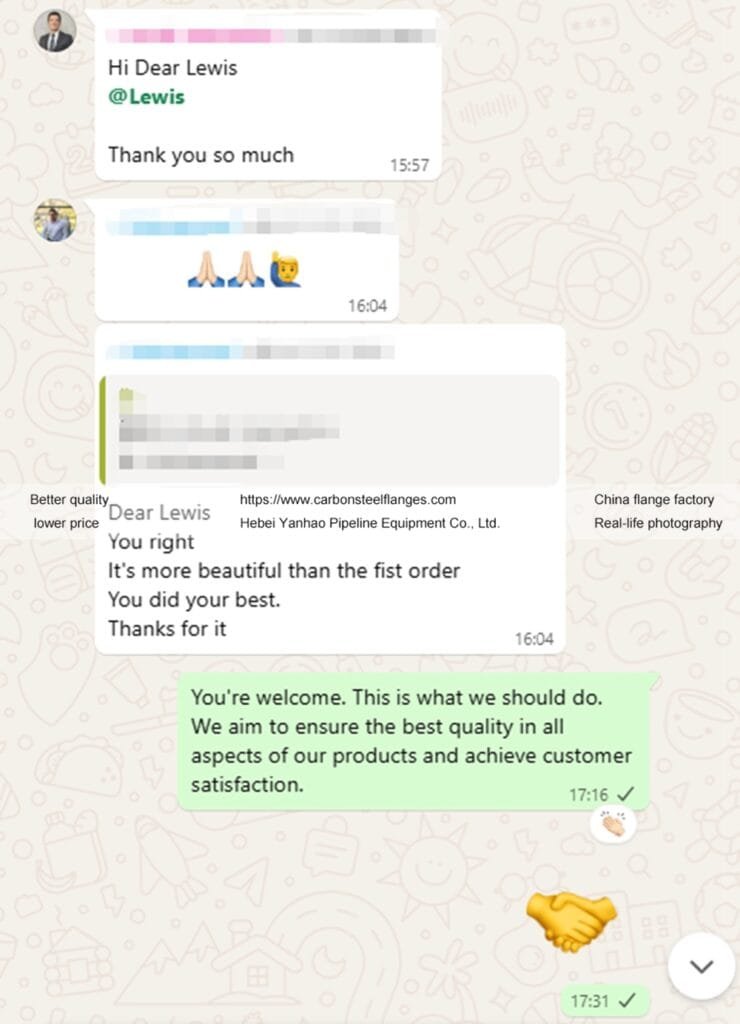

Once the customer received the product, they quickly sent us feedback: first, they praised the packaging, saying, “It’s sturdier than expected, and the accessories are intact after unpacking.” Then they added, “The product is even better than our first experience together. You truly did your best.” During the payment process, after seeing our updated commercial invoice, the customer immediately confirmed the final payment of $20,000 and even said, “I’ll contact you if I need anything later.”

Case & News

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.