Project Case: Custom Socket welding & Neck Welding Flange | Kyrgyzstan

Project details

Order Details

In November 2025, Hebei Yanhao reached a cooperation agreement with a Kyrgyz client for a flange order covering multiple specifications and categories.

At the beginning of the cooperation, the client made clear and detailed requirements for product specifications, involving multiple categories such as 150-pound 2-inch to 16-inch necked flat-face flanges, flange covers, and socket weld flanges.

To ensure that every detail accurately matched the project requirements, our sales and technical teams collaborated closely with the client, conducting multiple rounds of detailed confirmation with key parameters such as flange outer diameter, thickness, and bolt hole diameter. The client also demonstrated a high degree of professionalism and patience, jointly ensuring the accurate transmission of technical requirements.

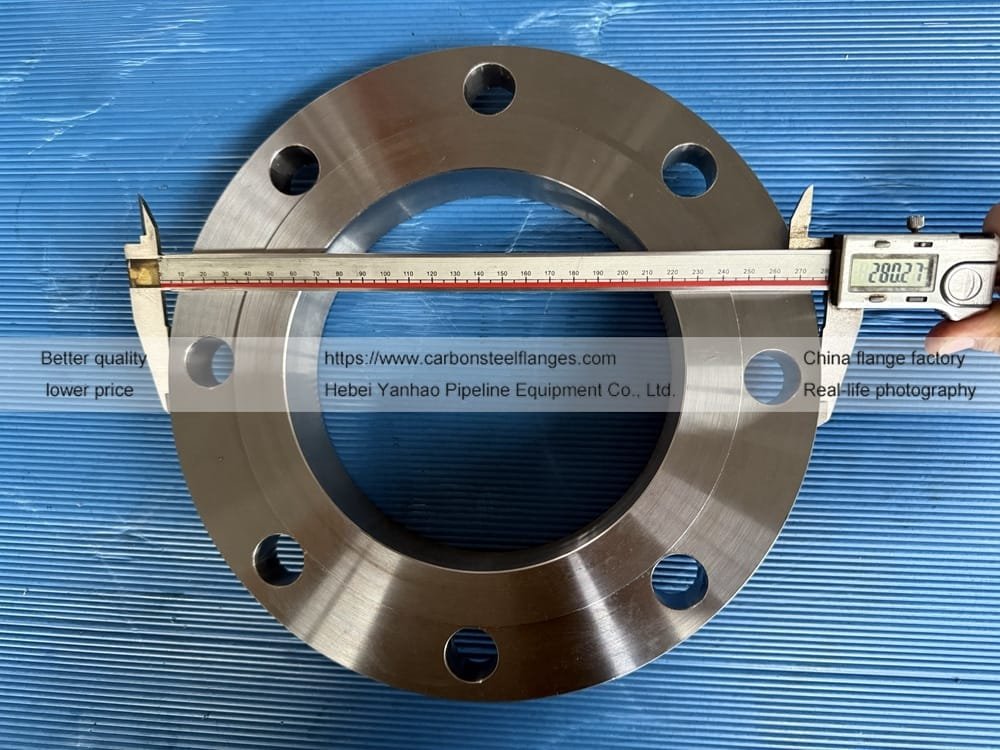

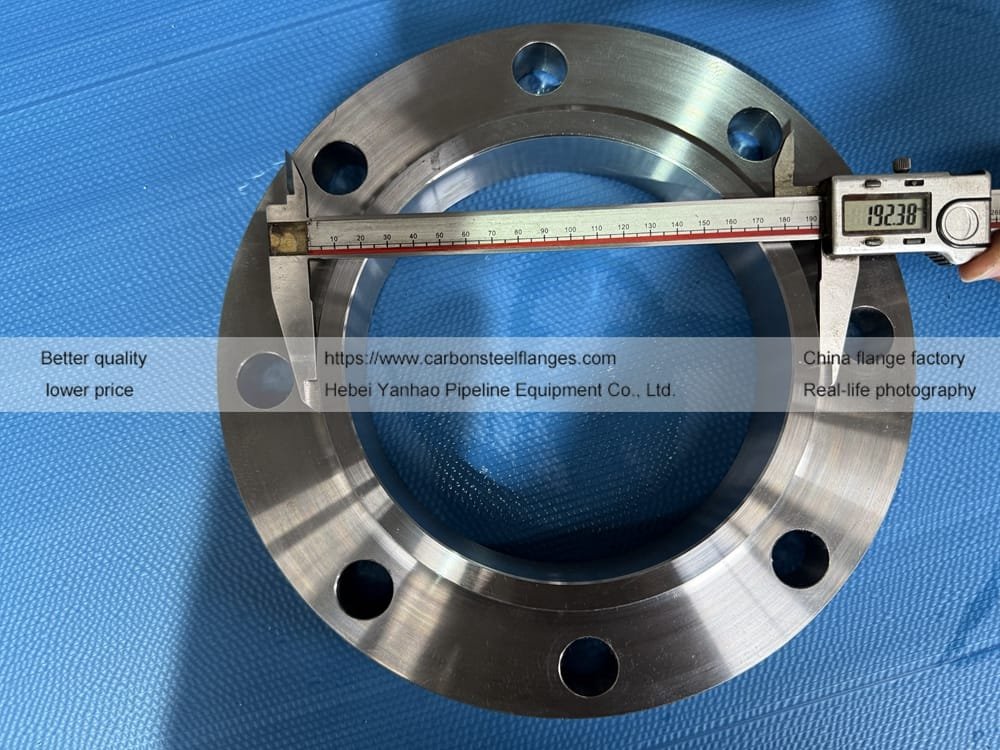

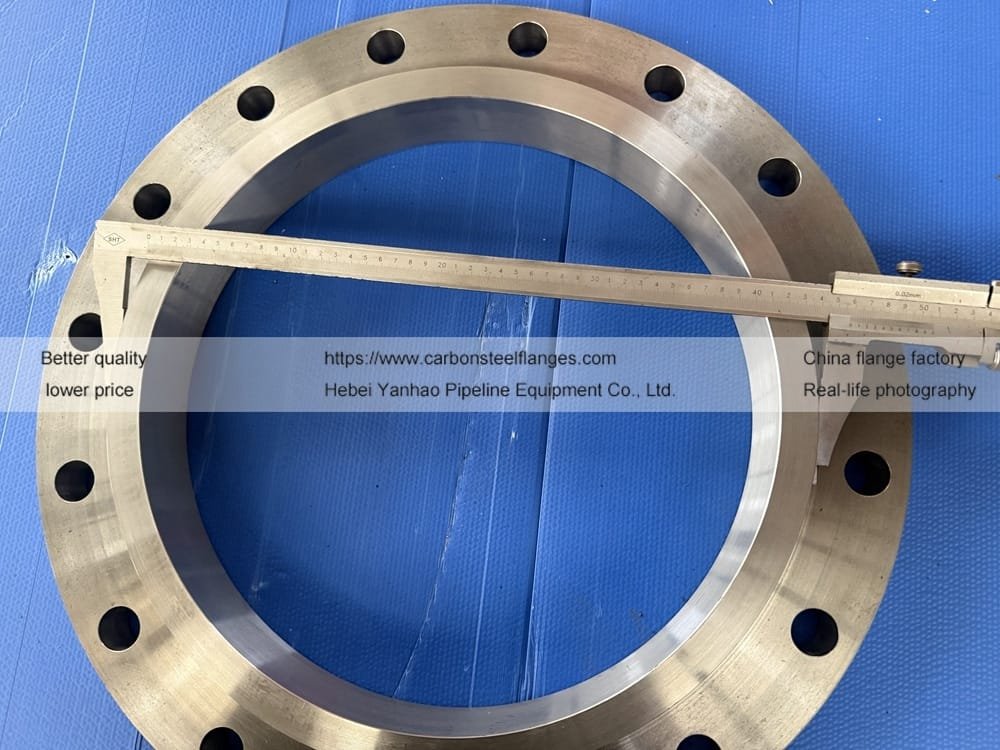

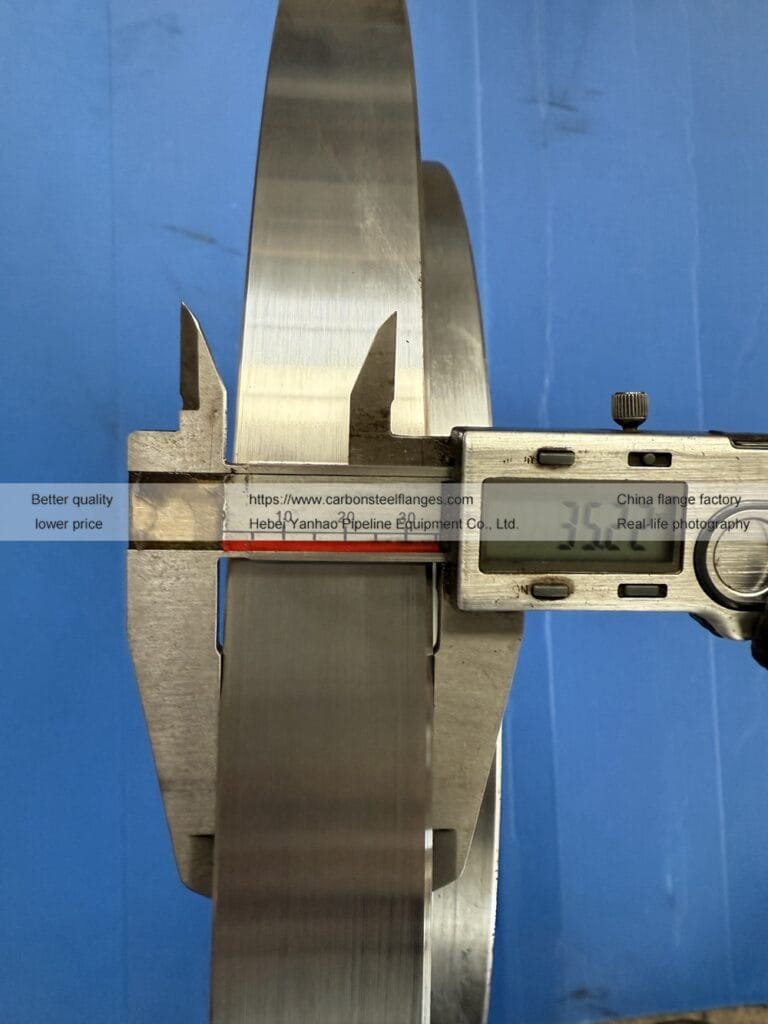

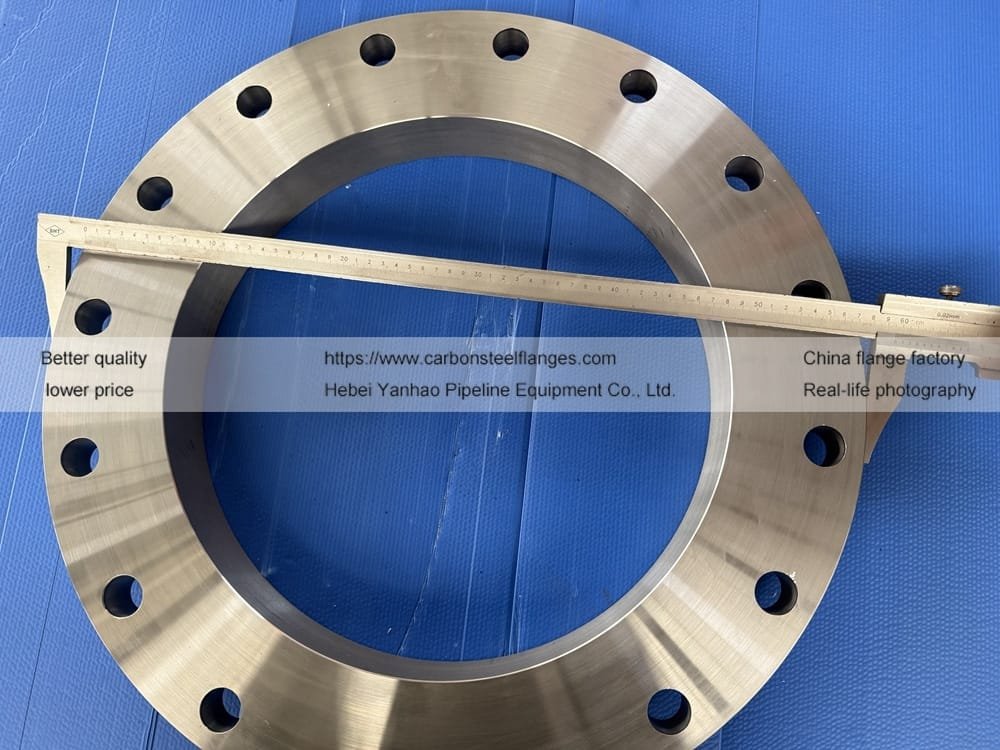

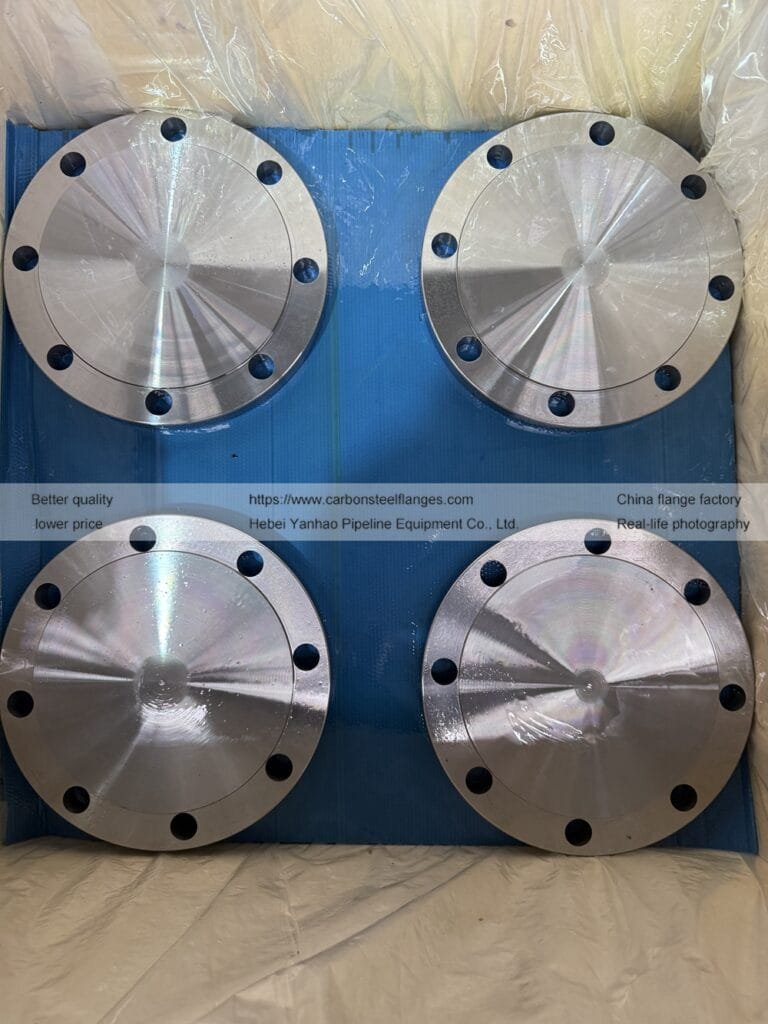

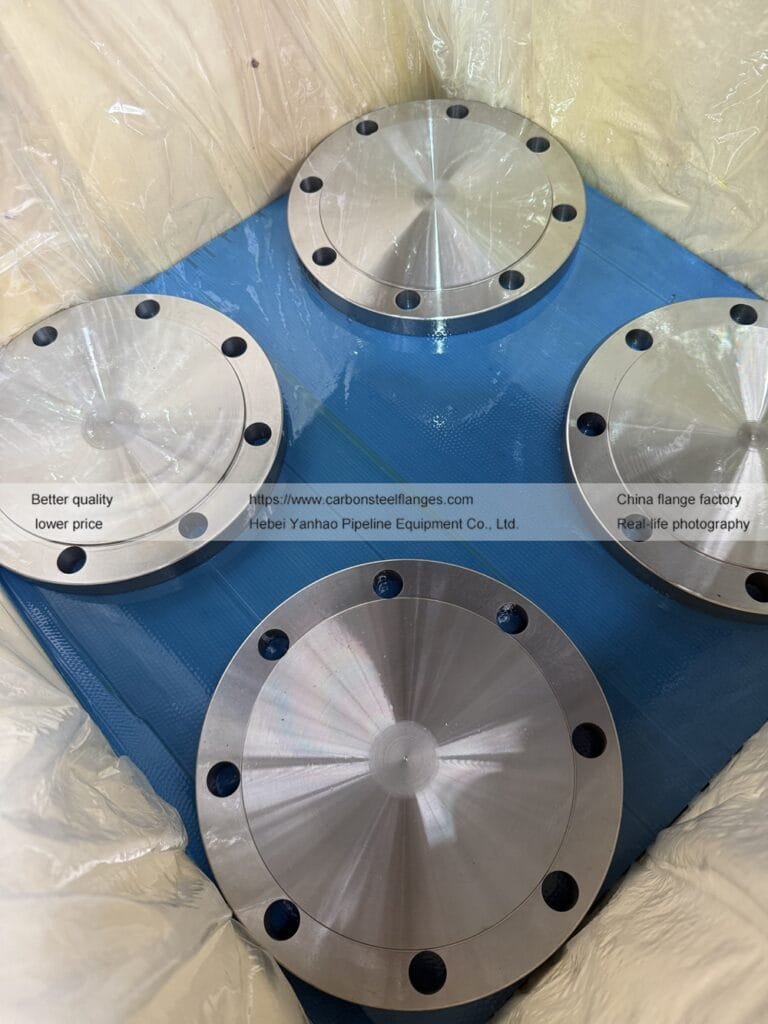

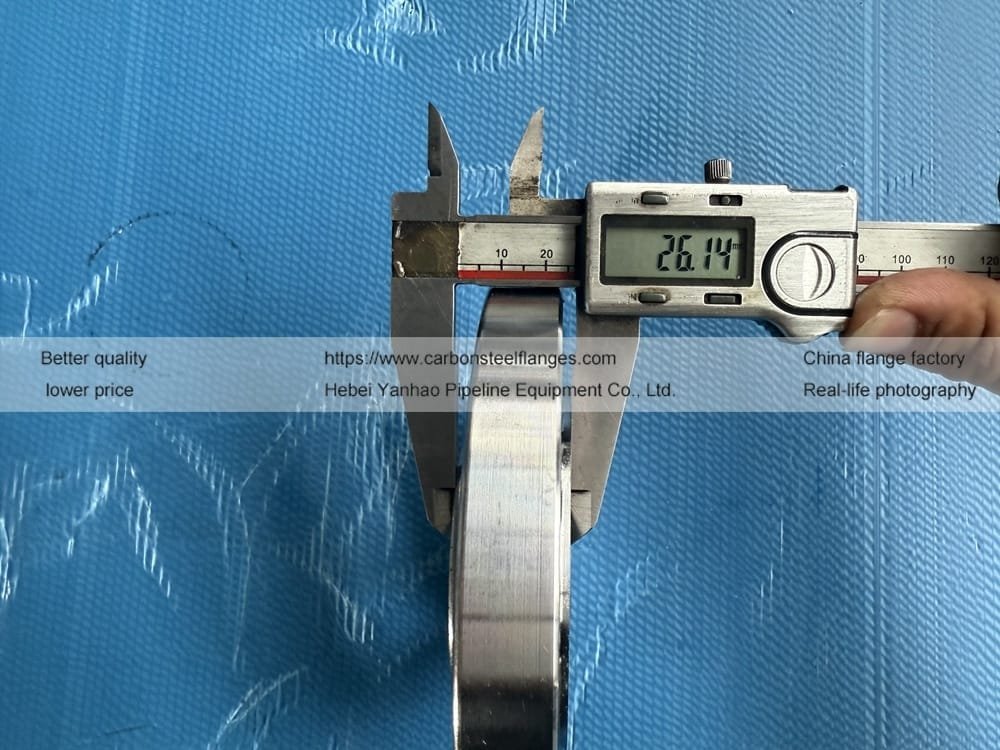

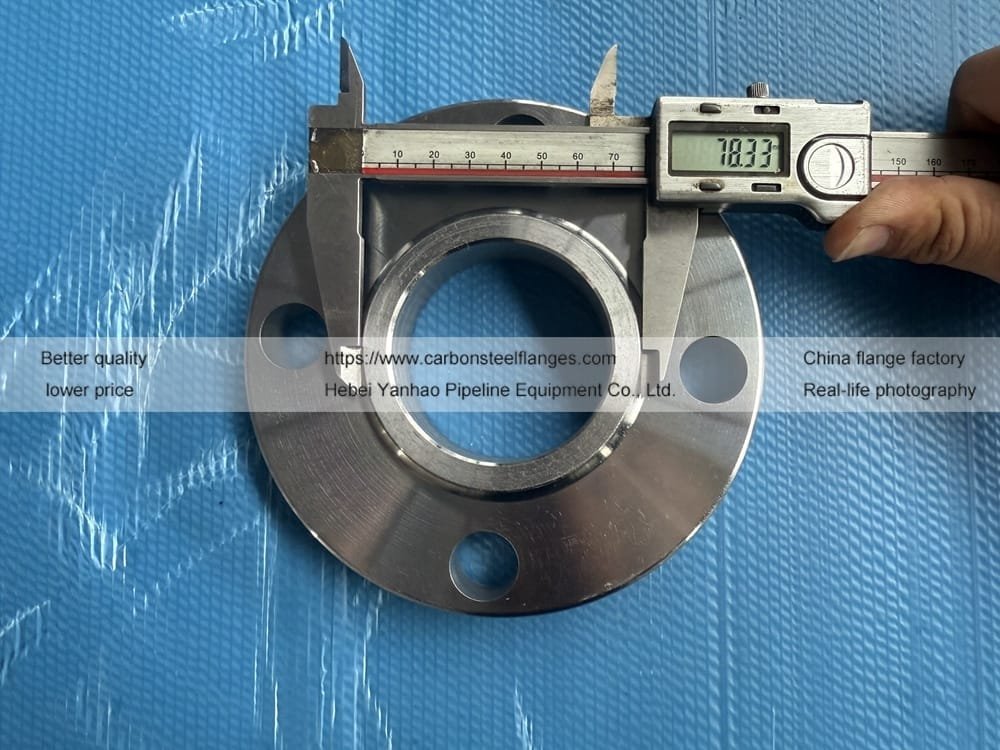

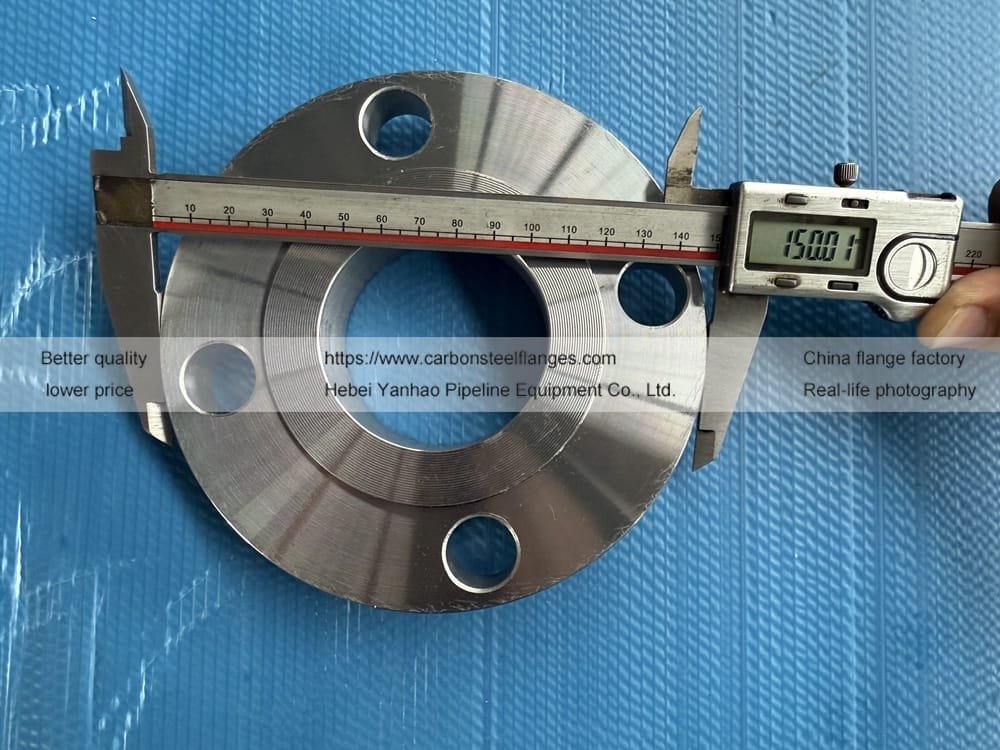

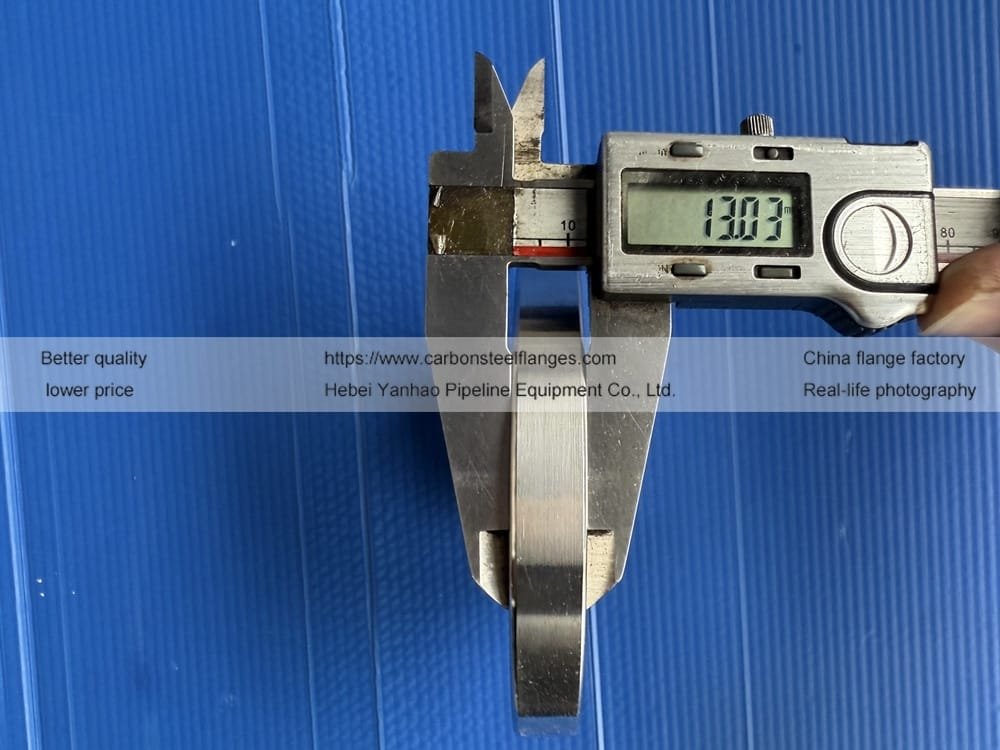

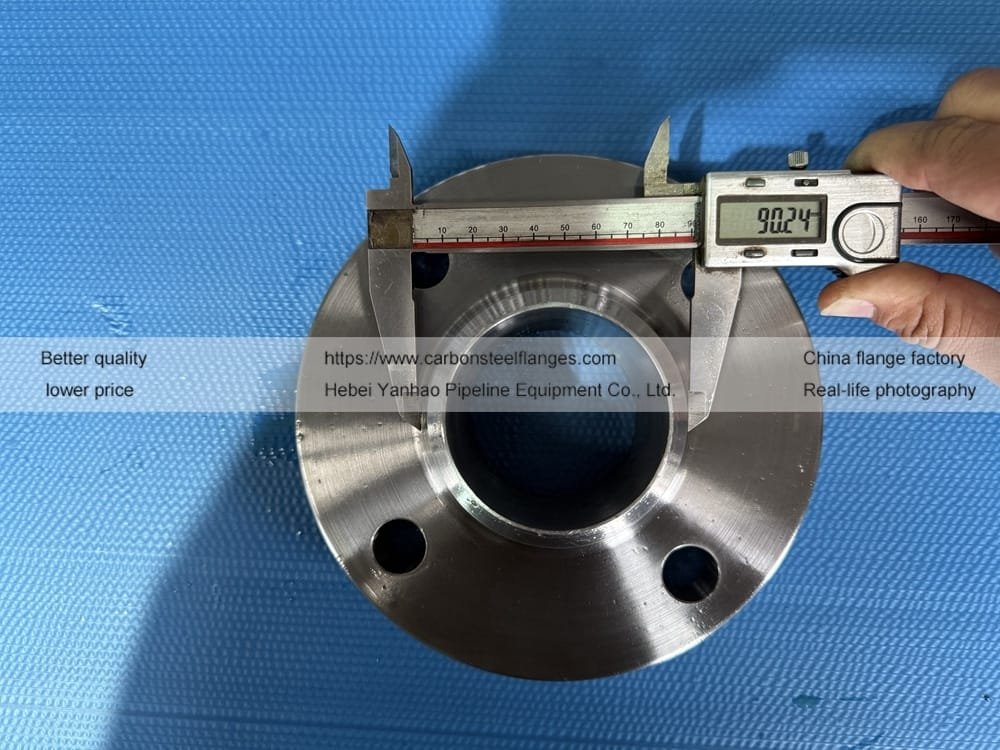

Once the order entered the production stage, the workshop team, based on mature processes and rich experience, carried out each stage of processing in an orderly manner. During the production process, we assigned dedicated personnel to follow up and regularly updated the client on the on-site status of key processes, including the process of using vernier calipers to accurately measure the flange inner and outer diameters. Taking a 150-pound 6-inch flange cover as an example, the team repeatedly calibrated the flatness of its sealing surface and the position of the bolt holes to ensure full compliance with standards.

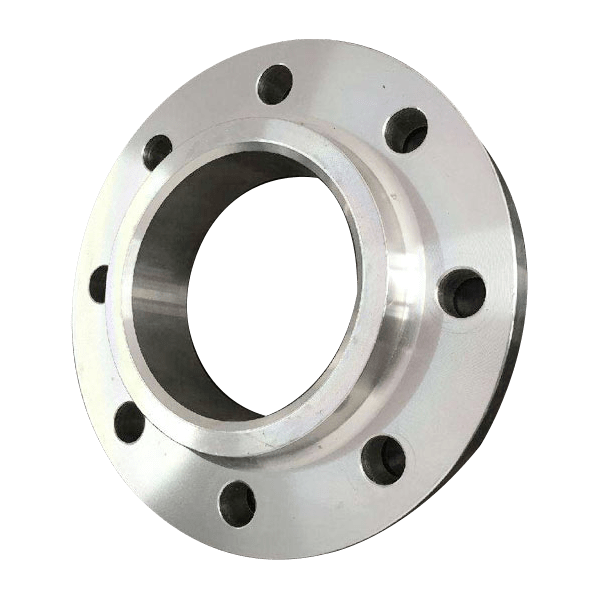

150-pound, 2-inch neck flat-face welding flange

150 lb, 8-inch weld neck flange

150 lb, 6-inch flange cover

150 lb, 1-inch socket weld flange (304)

150 lb, 2.5-inch weld neck flange

150 lb, 3-inch flange cover (304)

150 lb, 6-inch slip-on flange with neck

150 lb, 16-inch slip-on flange with neck

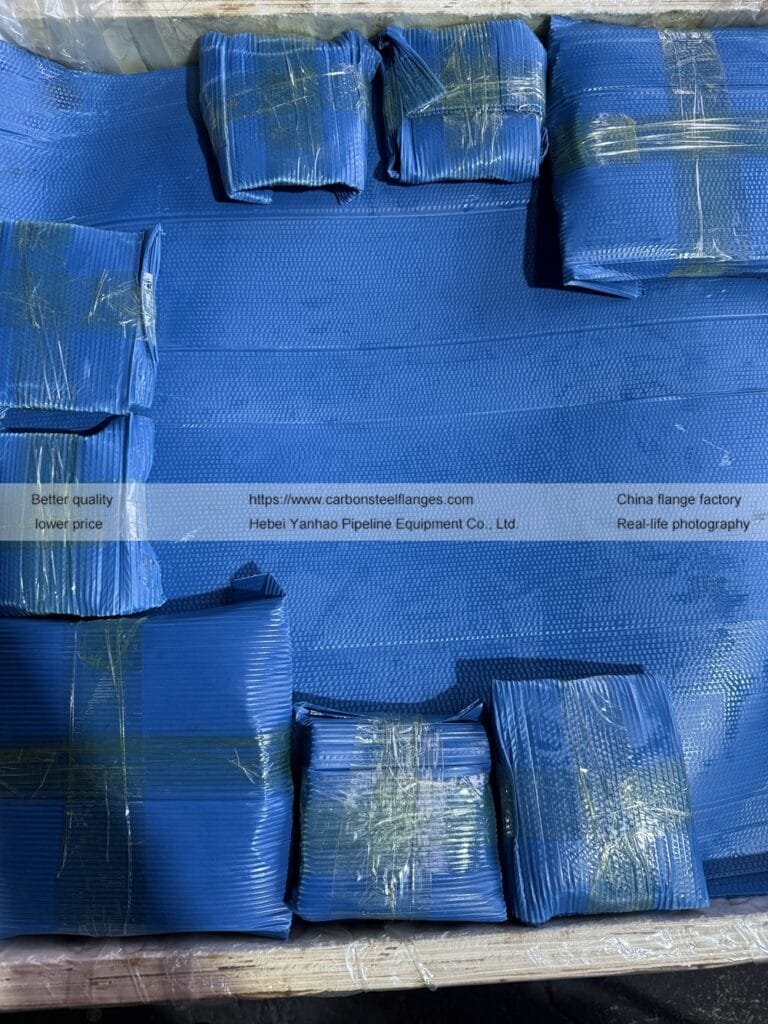

The packaging process also strictly adhered to long-distance transportation standards. To ensure the product arrived in Kyrgyzstan undamaged, we used custom-made wooden crates with professional filling and securing measures to effectively prevent potential bumps and deformations during transport.

After the goods were shipped, we immediately shared the logistics information with the customer, allowing them to monitor the transportation status in real time. Upon receiving the product, the customer expressed high satisfaction with both the flange quality and the professional packaging.

This cooperation further confirms that only by treating every detail with a professional attitude and responding to every trust with reliable quality can we win the continued recognition of our customers. Hebei Yanhao will continue to uphold this philosophy, providing global customers with even higher quality flange and pipe fitting products and services.

Case & News

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.

-768x1024.jpg)

-1-768x1024.jpg)