Project Case: Weld Neck Flange & Pipe Cap | Serbia

Project details

Order Details

In the summer of 2025, we established a partnership with a client in Serbia. At that time, the customer was urgently seeking a batch of high-quality flanges for an industrial project. Among numerous suppliers, our reputation for technical expertise and consistent product reliability distinguished us as their preferred choice.

From the initial discussions, the client emphasized their stringent requirements for flange quality and precision, as these factors were critical to the safety and stability of their project. Our sales team responded promptly, presenting in detail our production processes, quality control procedures, and the reliable sources of our raw materials.

Despite this, the client still expressed concerns regarding dimensional accuracy and material strength. To address these issues, our engineers engaged in multiple rounds of in-depth communication, providing technical explanations and sharing proven case studies. This professional support reassured the client and ultimately led to the successful signing of the order.

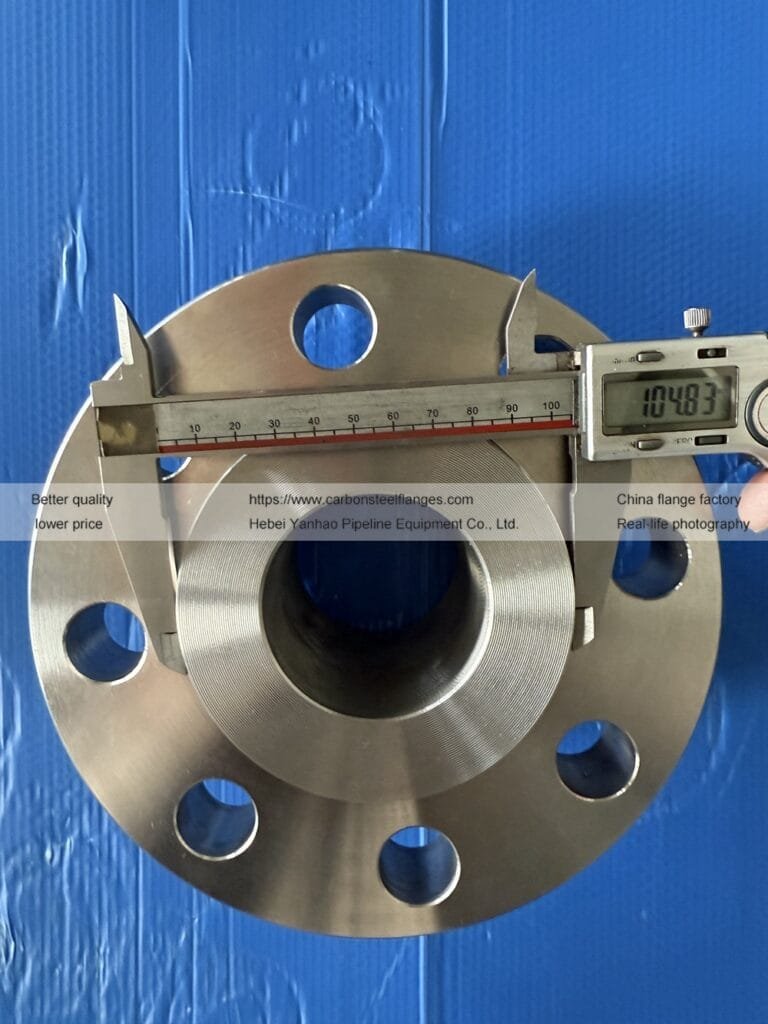

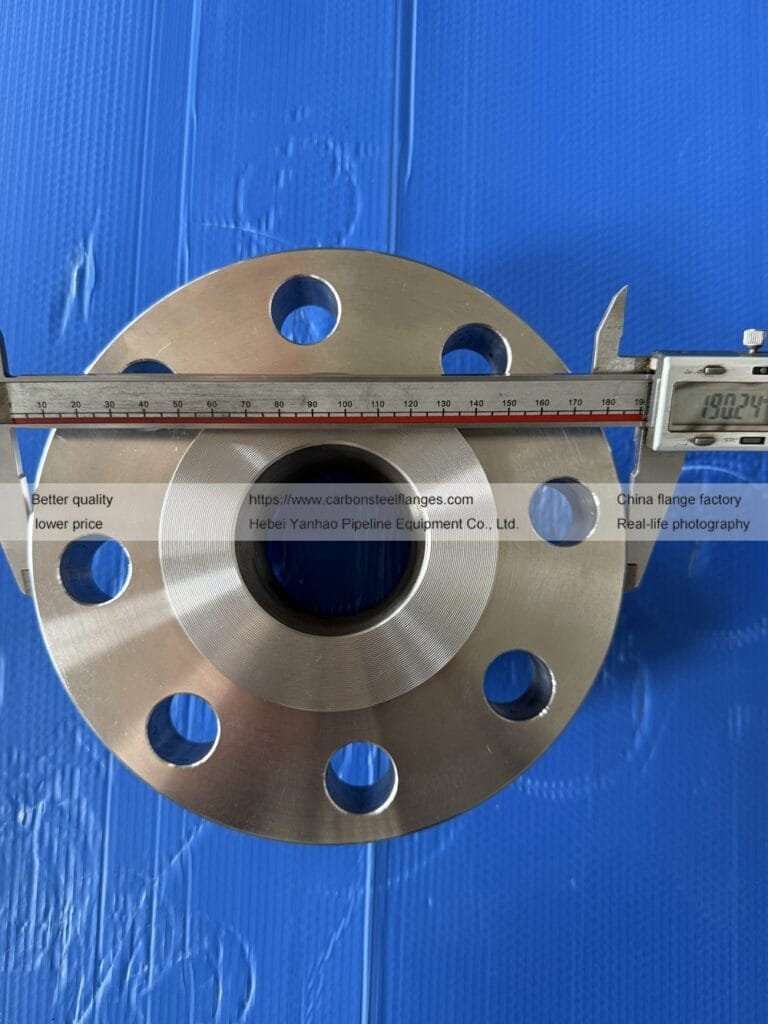

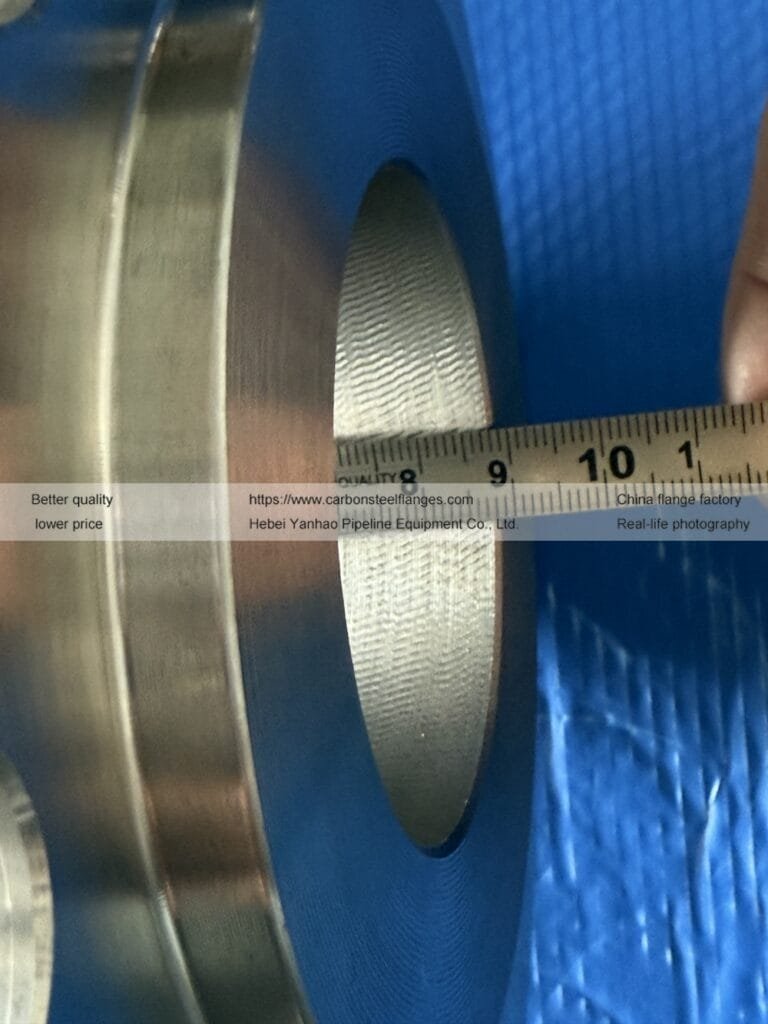

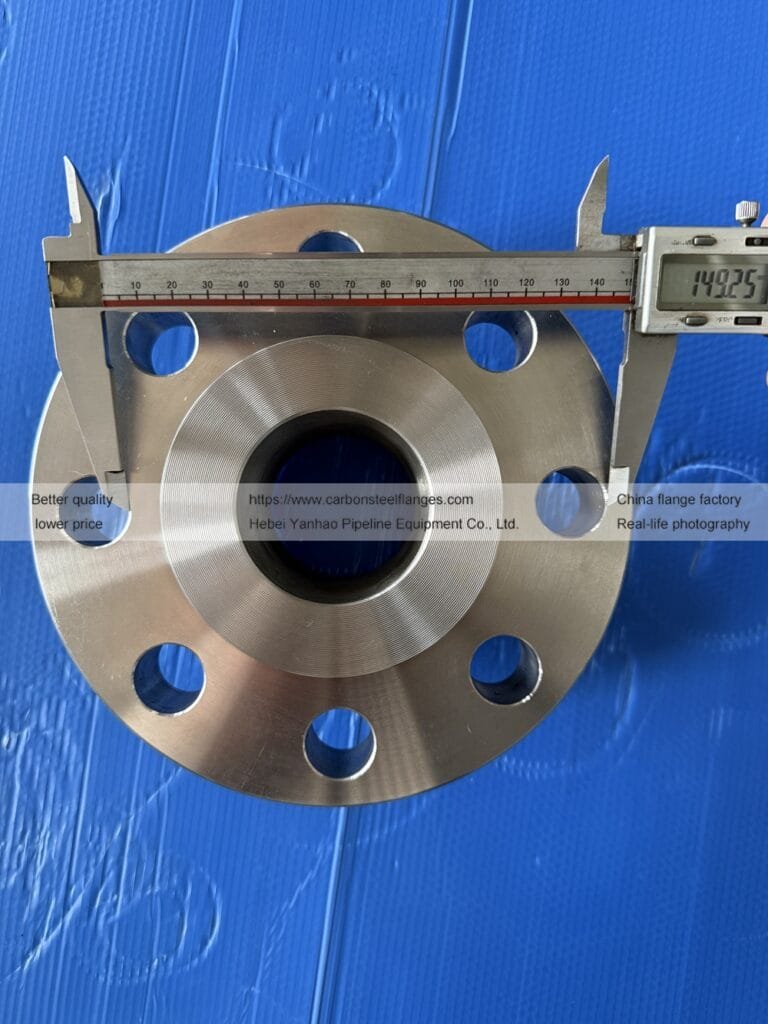

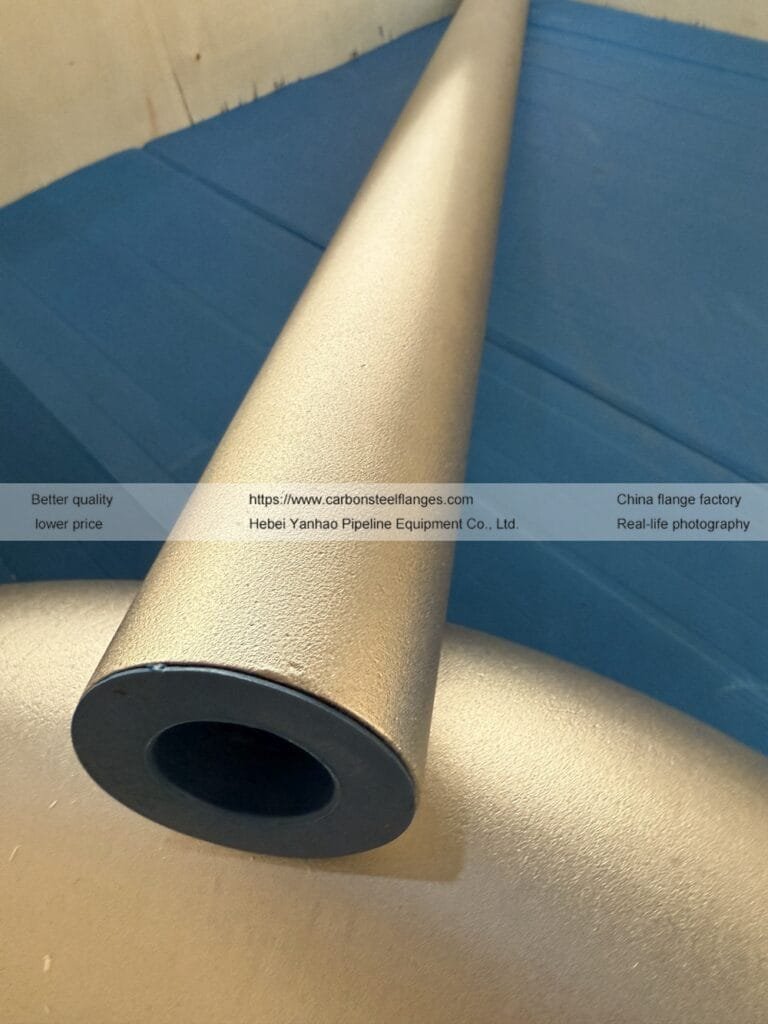

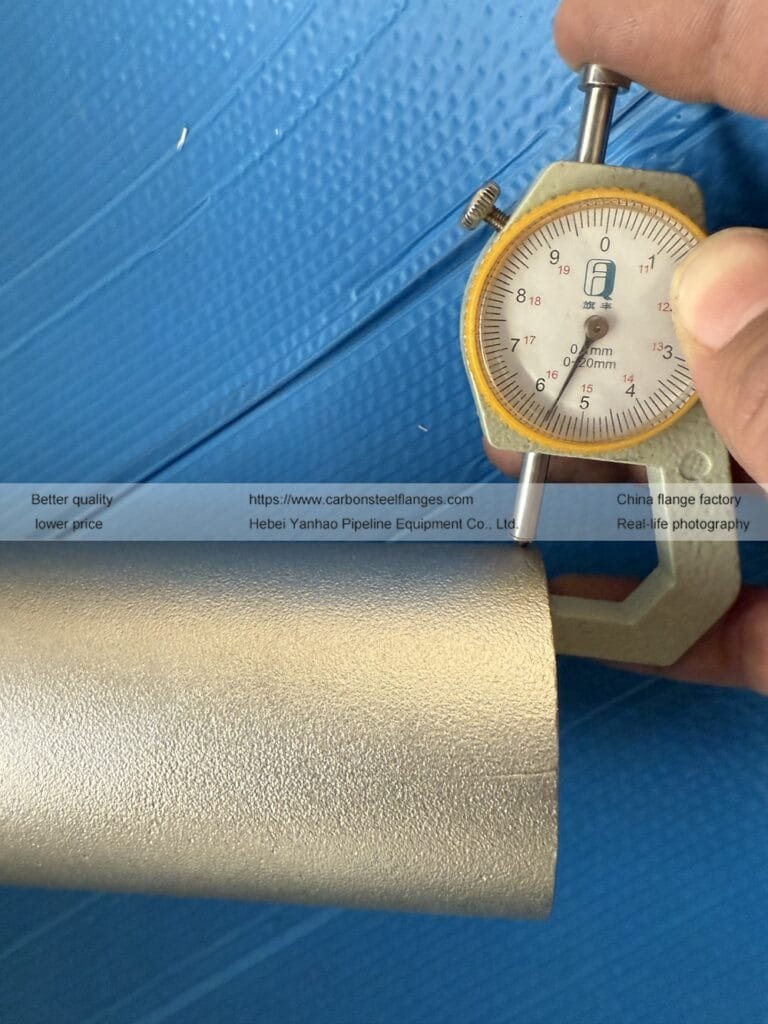

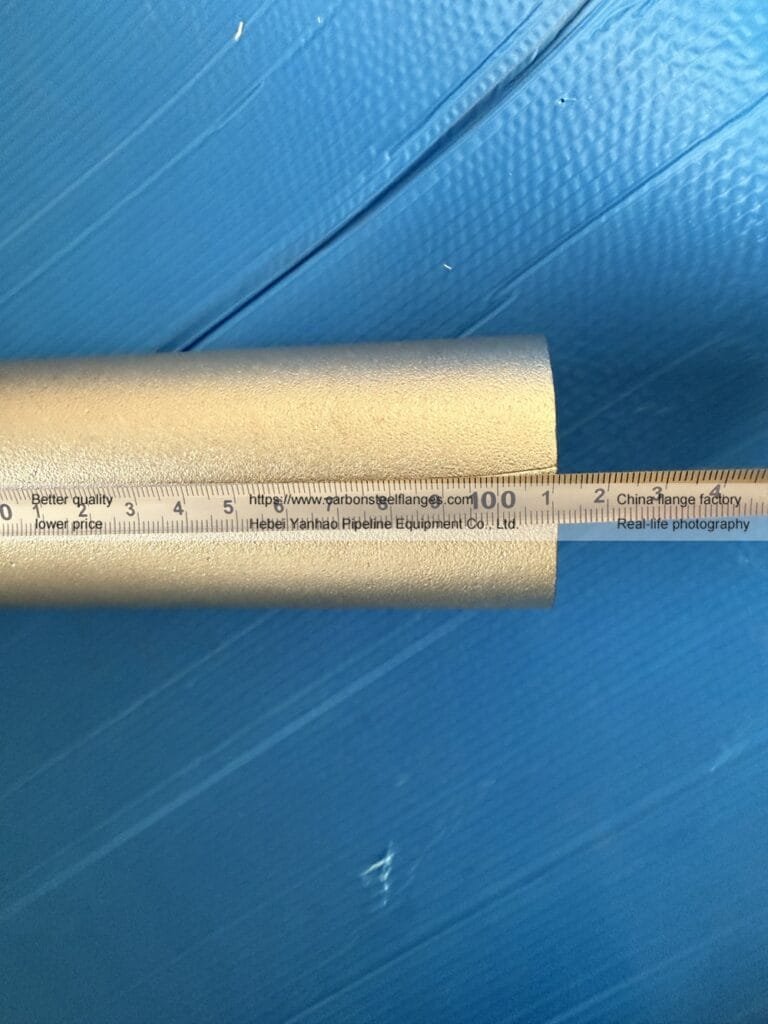

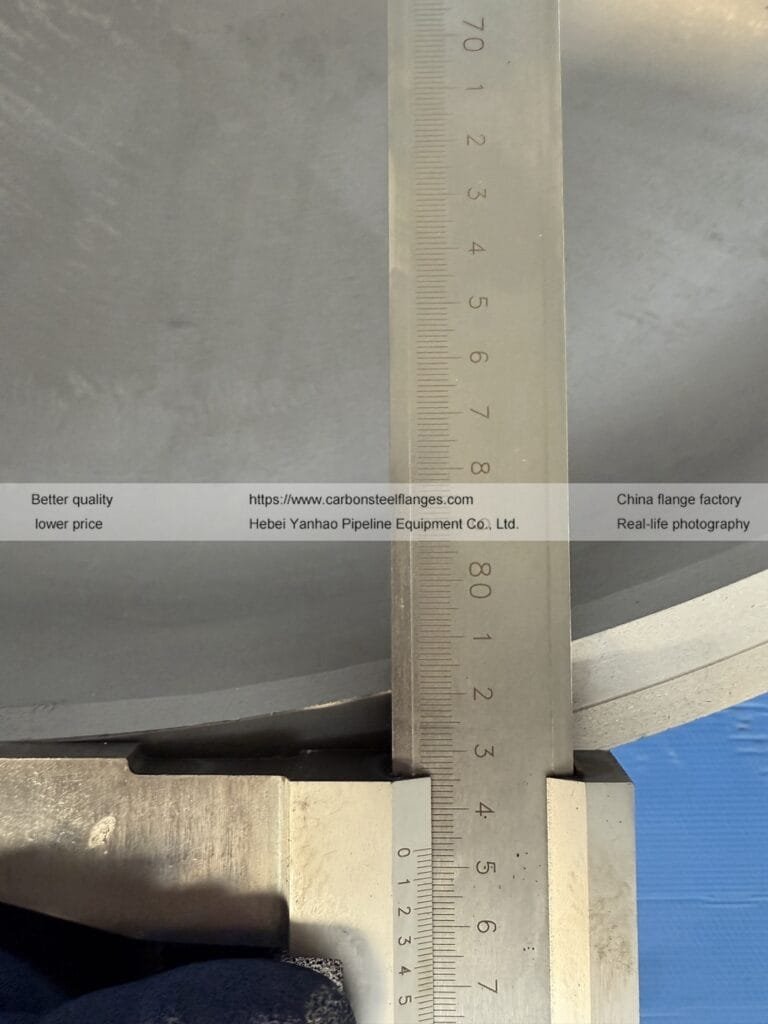

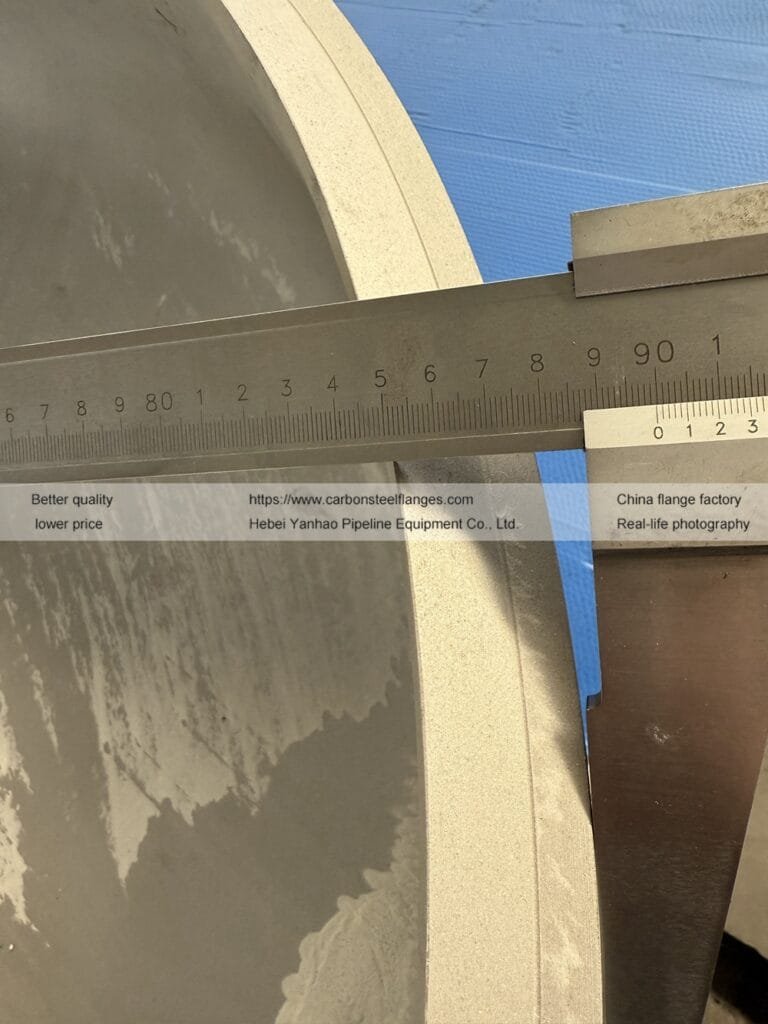

Once the order was confirmed, production began without delay. Each stage of the process was executed with meticulous attention to detail. Premium-grade steel was selected, and advanced CNC machining equipment was used to ensure precise manufacturing. During machining, precision measurement tools such as vernier calipers were employed to continuously check and adjust key dimensions—including inner and outer diameters, thickness, and bolt-hole sizes—ensuring complete accuracy.

Neck Welding Flange

| CLass600 DN15 (0.5 inch) |

| CLass600 DN25 (1 inch) |

| CLass600 DN50 (2 inch) |

| CLass600 DN65 (2.5 inch) |

| CLass600 DN80 (3 inch) |

| CLass600 DN100 (4 inch) |

| CLass600 DN400 (16 inch) |

| CLass600 DN400 (16 inch) |

Seamless Pipe

| Dia 21.34×3.73 |

| Dia 33.4×4.55 |

| Dia 60.33×5.54 |

| Dia 73.03×7.01 |

| Dia 88.9×7.62 |

| Dia 114.3×8.56 |

| Dia 355.6×12.7 |

Pipe Cap

| Dia 900 |

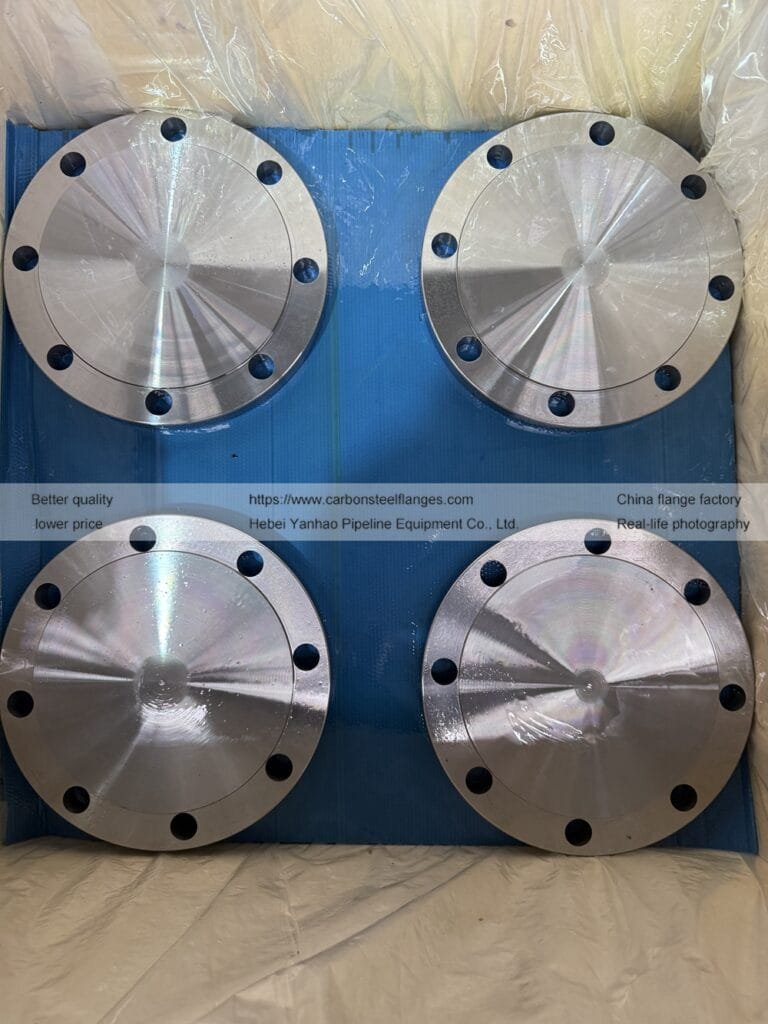

Equal care was applied to surface treatment. After processing, the flanges exhibited a smooth, mirror-like finish with a uniform metallic texture. This not only enhanced their appearance but also significantly improved resistance to corrosion and wear.

Upon completion, the products were packaged according to the client’s specifications. Reinforced wooden crates were used, with comprehensive protective measures inside each package to guarantee the flanges remained undamaged during long-distance transport.

Customer Testimonials

After receiving the product, the customer quickly sent us feedback. In the email, they happily stated, “Looks good. Thank you for fast work. You can arrange delivery.” They highly praised our product quality and work efficiency, and specifically mentioned that our flanges exceeded their expectations.

Case & News

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.