YANHAO Flange Precision Recognized by a Detail-Oriented Japanese Client

YANHAO recently established a deep partnership with a Japanese client known for their meticulousness. This client has extremely stringent requirements regarding the dimensional accuracy and surface finish of flange products. After the initial collaboration, they not only placed repeat orders but also proactively recommended us to their counterparts in Nagoya.

This all began last autumn. The client contacted us online, demonstrating a high level of professionalism from the outset, directly inquiring about specific indicators such as the diameter tolerance range of stainless steel blind flanges, the method for controlling bolt hole coaxiality, and whether the surface roughness could reach Ra1.6.

We responded with a quality inspection video of the actual production process, clearly demonstrating the use of a digital caliper to measure the flange hole diameter, with values accurate to two decimal places and fully conforming to international tolerance standards.

Learn More: Blind Flanges: Types, Uses, and Key Features

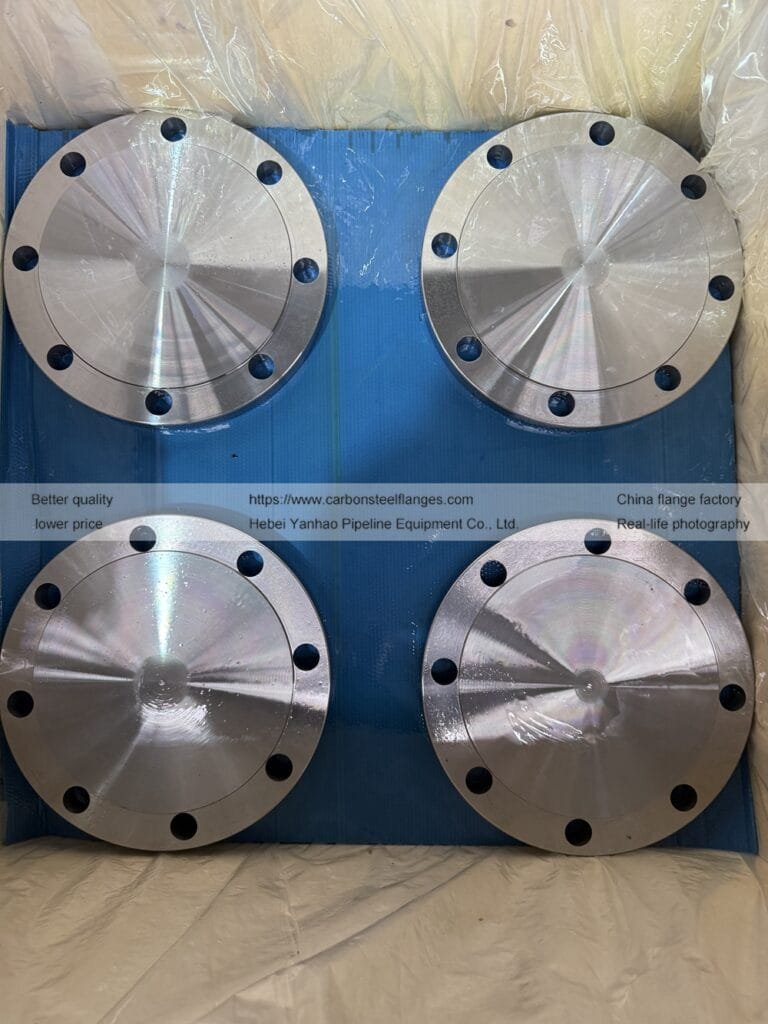

To further verify the quality, the client visited the factory last November. During the tour of the stainless steel processing area, they showed great interest in the mirror-finish sealing surfaces machined by CNC boring machines, examining them closely with a magnifying glass.

During the process, the customer paid particular attention to the measured bolt hole diameter – 30.12mm as displayed on the digital caliper, perfectly matching the 30mm + 0.15mm tolerance specified in the drawing. The customer expressed their approval, stating, “This level of craftsmanship surpasses many factories I’ve seen in Japan.”

The customer also highly praised Yanhao’s quality control process. We implement a “three-inspection system”: self-inspection, mutual inspection, and specialized inspection, ensuring that every flange, from raw material spectral analysis to dimensional recording during processing and final hydrostatic testing, is fully traceable and all data is clear and accurate.

The packaging also won the customer’s praise. Each flange was individually wrapped in bubble wrap and protected by a custom-made wooden crate with a detailed packing list specifying product specifications and quantity. After receiving the goods, the customer commented, “The packaging is professional; there was zero damage during long-distance transport. We felt your dedication.”

Currently, this customer has established a long-term cooperative relationship with Hebei Yanhao and has actively recommended the company to other industry peers. As stated in their recommendation email, “Yanhao’s flanges boast high precision and stable quality, making cooperation a very reliable partnership.”

We firmly believe that no matter where our clients come from, only by consistently adhering to the highest quality and providing attentive service can we earn lasting trust. If you are looking for a reliable flange supplier or wish to inspect our production processes in person, you are welcome to visit Hebei Yanhao at any time—we are happy to showcase every detail and establish cooperation based on our strength and sincerity.

Case & News

Author: Lewis Liu

Hello, my name is Lewis Liu, and I’m a professional sales engineer with over a decade of expertise in the flange fittings sector.

I am quite informed about flange selection, installation, and maintenance. I am passionate about providing customers with the greatest solutions for keeping their pipeline systems running smoothly, safely, and dependably.

If you have any queries or concerns concerning flange fittings for your pipelines, whether they are about selection, material choice, specification requirements, or anything else, please contact me at any time. I am dedicated to providing expert advice and assistance to help you make educated decisions and reach your objectives.